Lantek Workshop (Manager, Wos, Capture)

$ 150.00

The MES software that will boost the productivity of your factory

Lantek Workshop is the family of Lantek products intended for companies who wish to acquire a complete and competitive solution to manage and optimize their manufacturing processes, having real time control of all the different activities taking place in the workshop.

Description

Lantek Manager

Lantek Manager simplifies and speeds up all the manufacturing processes and optimizes the assigned costs and the delivery dates to the maximum.

Lantek Manager simplifies and speeds up all the manufacturing processes and optimizes the assigned costs and the delivery dates to the maximum.

Lantek Manager is designed for companies interested in a complete and competitive solution capable of enhancing its manufacturing processes and integration with CAD/CAM solutions.

Imagine being able to know, in real time, the status of each one of the parts or/and customer manufacturing orders. Imagine being able to have an optimized view considering different key variables in the workshop: delivery date, customer, sales order, machine, material and thickness, among other things.

The system takes into account different types of manufacturing requirements: planned from the management solution or from geometries like DWG, DXF files etc.

Product Specifications

Product Specifications

Monitoring of the manufacturing process

For monitoring of a manufacturing order, the system has advanced functions for grouping the parts according to different criteria, such as: machine, material, thickness, delivery date, sales order, customer, etc.

The user can check, in real time, the status of the manufacturing product and discover whether it is: stand-by, nesting, under production or finished. All statuses are graphical and managed intuitively. Through different graphic indicators, it is possible to view the manufacturing evolution.

-

.jpg)

2D job planning

Times and costs optimization

Considering the machine load, it is possible to optimize the launching of orders and the generation of CAD/CAM jobs.

The system takes into account different types of manufacturing requirements either planned from the management solution, or imported from geometry like DWG, DXF files, etc.

-

.jpg)

Production order time & cost

Workshop management

Lantek Manager has the ability to monitor the volume of work, to manage completed operations, and to optimize resources, such as employees, machines, and sub-contracting centers. From the office, it is possible to reserve materials for a specific job or to give priority to other jobs.

Lantek Manager connects with third party workshop data solutions and allows the logging of times and real material consumption for each nest and production process.

-

.jpg)

Workshop management

Analysis and history of products

Lantek Manager performs a comparison between estimated costs and true costs for selected manufacturing orders. It also allows specific evaluation of those orders and their associated products. Customers can enter and continuously update costs data, as well as capture industry costs from the web.

Lantek Manager provides powerful business analytics tools which arm managers with the information they need to continually improve production times and methods. These tools cover manufacturing orders, incurred costs, volume of work, change orders, etc.

Lantek Manager provides manufacturers with technology tables that they populate based on machines and their features. It also contains an advanced sales manufacturing history record management.

-

.jpg)

Production history

-

.jpg)

Reporting history

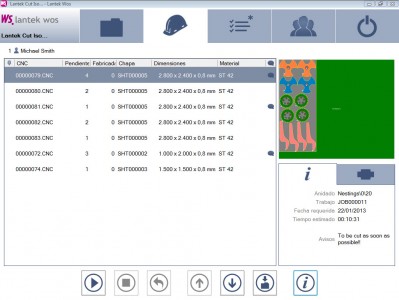

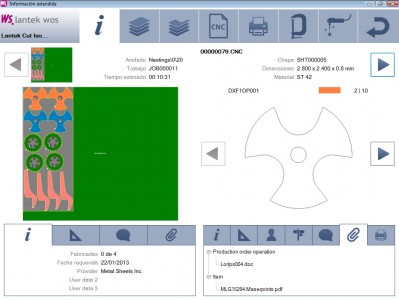

Lantek Wos

Lantek Wos is designed specifically to meet the needs of companies working with sheet metal. It is a system created to help control and monitor production. This system provides all the tools necessary to collect data during the production process, i.e., status, manpower, materials, machines, inventory, etc.

Lantek Wos is designed specifically to meet the needs of companies working with sheet metal. It is a system created to help control and monitor production. This system provides all the tools necessary to collect data during the production process, i.e., status, manpower, materials, machines, inventory, etc.

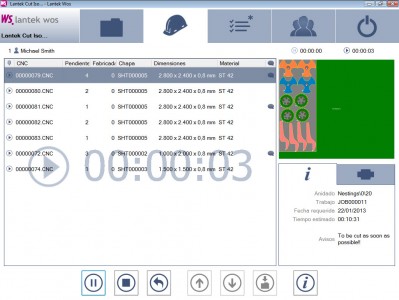

The system is updated from the workshop with validated data, in real time, and provides management with an accurate and current view of the information.

Lantek Wos can be installed on a PC. The system offers options for choosing different machine tools and work centers for production processes. It is also possible to communicate from remote locations to the machine controls in the workshop.

With Lantek Wos, the work center operators have all the information related to work in progress on hand. They also have the ability to consult and/or monitor warehouse inventory.

Product Specifications

Product Specifications

Easy to Use

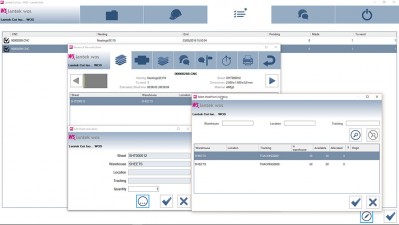

The main goal of Lantek Wos is to provide an easy to use and efficient solution for workshop data input. With intuitive screens and a minimal need for data entry, information is clear.

Anyone is capable of interaction with WOS, even without previous knowledge of the system.

Lantek Wos represents the perfect balance between ease of use, power and function, all critical requirements in the production sector.

Lantek Wos includes multiple options that are associated with nesting and manufacturing operations for full display of information. To list a few options:

- 2D nest design

- A status list of pending nests

- The ability to re-order the sequence of jobs

- The ability to change the machine tool

- Turret configuration (for punching machines)

- Numerical control (CNC) of the nests

- Parts data review

- Users may check each of the parts that comprise the nest and their quantity, length, height, related order, etc.

- Process and machine times

- Graphic and intuitive displays of operations and nests status

-

Interface

Monitoring and Validation of the Manufacturing Process

Designed for integration with Lantek Expert, our CAD/CAM programming system, Lantek Manager, our production management system, and Lantek Integra, ERP system, Lantek Wos allows the production manager to specify which work center or machine is to carry out each job.

These solutions make it possible to monitor nesting in real time and verify the production of any order at any given time. The operator can display all the necessary information to validate the pending and assigned work.

-

Job view

-

Job monitoring

Warehouse Management

Lantek Wos allows the user to select the actual sheet used to cut the nest and retain traceability. Lantek Wos automatically updates the warehouse. Cut sheets are registered and removed from inventory. Parts and remnants are registered and accounted for also.

Parts that have been lost during the production process can be registered to help manage processing and quality control.

-

Sheet selection

Productivity Increase

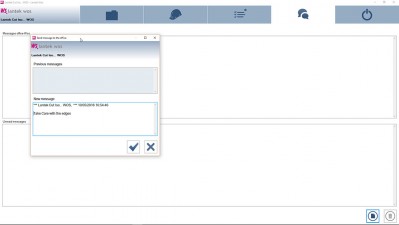

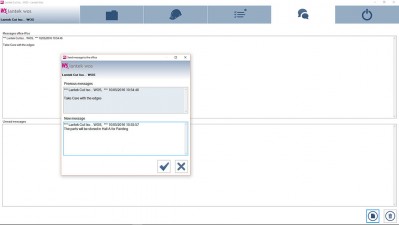

Lantek Wos registers and updates all data immediately, making the system an essential decision-making tool. Paper use is minimal and unnecessary administrative tasks are removed. Lantek Wos helps optimize productivity and reduce manufacturing costs.

-

Office-Operator communication

-

Office-Operator communication

Lantek Workshop Capture

Lantek Workshop Capture is a data capture software program that is fully integrated with Lantek Integra. The various operations performed in the company workshop can be managed and monitored using this software. Plant operators can enter data in real-time from any location, e.g. production time, downtime, job status and information on the operations to be performed.

Lantek Workshop Capture is a data capture software program that is fully integrated with Lantek Integra. The various operations performed in the company workshop can be managed and monitored using this software. Plant operators can enter data in real-time from any location, e.g. production time, downtime, job status and information on the operations to be performed.

Product Specifications

Product Specifications

Main features

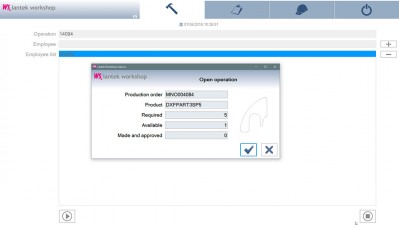

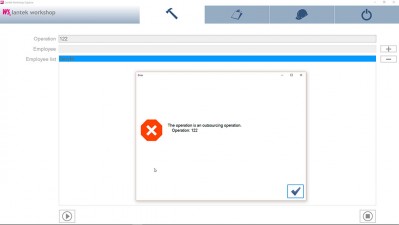

Lantek Workshop Capture has features which include adaptation to mobile devices (smartphones and tablets) and basic bar code readers, compatibility with various Windows platform-based operating systems, and the capability to validate operations from anywhere by connecting to the server from a mobile device.

There are two ways to identify the user who is due to start work in the workshop and to transmit information: Either the touch screen can be used (where work to be performed or completed can be typed in by hand) or the bar code reader can be used. In this way, data is easily captured on the factory floor without causing errors or any downtime.

-

Operation validation

Essential tool for decision-making times

This is the main goal sought by Lantek Workshop Capture. By redesigning its graphical interface, the application now has clear screens, easy access, and minimal data for the operator to enter. This ensures that factory floor data is registered correctly at the time when it is produced – eliminating superfluous tasks and transcription errors.

Another advantage that facilitates decision-making is that the required information is sent to the manager as soon as it is produced and data is updated in real time.

A management system aims to provide authenticated information when necessary. For that to happen, the system must be supplied with valid and updated data, which is fully achievable with this application.

Lantek Workshop Capture can be used to integrate all the company´s operations within a single system and to report on what happens in the workshop. The operator can halt the process or identify deviations at the time when they occur.

Lantek has fully developed this factory floor data collection system such that it does not require the addition of third-party applications and ensures full integration with Lantek Integra.

Additionally, this tool is not only designed for cutting operations, but for all operations that exist within the company. It can even be used to record the entry and exit times of employees, or the beginning and end of a job or a task. Thus, all the processes carried out in the factory are monitored, while a comprehensive record is kept of everything that occurs in the workshop.

Thanks to Lantek Workshop Capture, developed by Lantek and fully integrated with Lantek Integra, workshop-related data and information can be received by companies that process sheet metal, tubes, and profiles. The data is in real-time and received in an easy, flexible way, including via mobile devices. Lantek Workshop Capture offers complete data management and analysis and supports the informed decision making process.

-

Operator support