WORKNC 2025.2 relrease 25

$ 170.00

WorkNC CAD/CAM Software – Advanced CNC Programming Solution

WorkNC is a powerful CAD/CAM software for 2 to 5-axis CNC machining, widely used in automotive, aerospace, mold, and dental industries. Automate toolpath generation, optimize machining efficiency, and reduce setup time with advanced collision detection, high-speed milling, and multi-part machining capabilities. Compatible with major CAD formats like CATIA, SolidWorks, STEP, and IGES. Perfect for precision manufacturing and complex geometries…

Description

WorkNC 2025 CAD/CAM Software – Complete CNC Programming & High-Precision Machining Solution

WorkNC 2025 is the latest professional CAD/CAM software from Hexagon, specifically designed for high-precision CNC machining in automotive, aerospace, mold & die, tooling, medical, and dental industries. Renowned for its intelligent automation and reliability, WorkNC streamlines CNC programming, reduces setup time, and optimizes machining efficiency across 2 to 5-axis operations.

WorkNC is a comprehensive CAD/CAM software suite developed by Sescoi, now part of Hexagon Manufacturing Intelligence. Since its inception in 1988, WorkNC has been a leading solution for automating CNC programming, particularly in industries requiring high-precision machining, such as automotive, aerospace, and tooling.

🔧 Key Features of WorkNC

-

Multi-Axis Machining: Supports 2 to 5-axis CNC programming, including simultaneous 4 and 5-axis toolpaths, ideal for complex geometries like impellers, turbine blades, and molds

-

Automated Toolpath Generation: Offers intelligent automation for toolpath creation, reducing manual input and programming time

-

Advanced Toolpath Strategies: Includes high-speed machining techniques such as trochoidal roughing and rest material finishing

-

Collision Detection: Ensures safety by detecting potential collisions during the machining process

-

Integration with CAD Systems: Seamlessly integrates with leading CAD software for enhanced design and workflow compatibility

-

Advanced Parallel Processing: Utilizes multi-threading to calculate up to four toolpaths simultaneously per work zone, significantly reducing processing time

🛠️ Specialized Modules

-

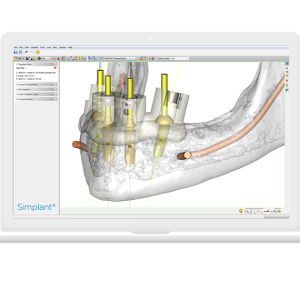

WorkNC Dental: Tailored for dental applications, this module automates the machining of prosthetic appliances, implants, and crowns, supporting 3 to 5-axis toolpaths and offering an open system compatible with various CAD platforms.

-

WorkNC MPM (Multi-Part Machining): Allows simultaneous machining of multiple parts on the same machine, optimizing tool changes and reducing setup time.

-

WorkNC LMP (Layer Milling Process): Enables layer-by-layer machining, ideal for deep and narrow cavities, enhancing precision and reducing material waste.

📂 Supported CAD Formats

WorkNC is compatible with a wide range of CAD file formats, including:

-

DXF

-

STEP

-

IGES

-

CATIA V4 & V5

-

Unigraphics

-

SolidWorks

-

SolidEdge

-

Pro/E

-

Parasolid

-

STL

🏭 Industry Applications

WorkNC is widely used in industries such as:

-

Automotive

-

Aerospace

-

Mold and Die Manufacturing

-

Tooling

-

Medical Device Manufacturing

-

Dental Laboratories

Its versatility and automation capabilities make it a preferred choice for manufacturers requiring high-precision and efficient CNC programming solutions.

New Features & Highlights

-

Advanced Multi-Axis Machining: Fully supports 2 to 5-axis CNC programming, including simultaneous 4- and 5-axis toolpaths, enabling machining of complex shapes such as turbine blades, impellers, molds, and intricate dental components.

-

High-Speed Machining (HSM) Strategies: Enhanced trochoidal roughing, adaptive rest material finishing, and high-speed pocket milling for smoother cuts, longer tool life, and faster production.

-

Automated Toolpath Generation: Intelligent algorithms automatically generate collision-free, optimized toolpaths with minimal manual input, reducing programming errors and production delays.

-

Multi-Part Machining (MPM): Efficiently machine multiple components simultaneously on a single setup, significantly increasing productivity and minimizing tool changes.

-

Layer Milling Process (LMP): Precise layer-by-layer machining for deep cavities or narrow features, reducing material waste and improving machining accuracy.

-

Parallel Processing & Performance Optimization: Multi-threading allows up to four toolpaths to be calculated simultaneously per work zone, speeding up processing and reducing waiting times.

-

Collision & Safety Enhancements: Advanced detection systems prevent crashes, protect expensive tools, and maintain optimal machining conditions.

-

Seamless CAD Integration: WorkNC 2025 supports a wide range of CAD formats including CATIA V4/V5, SolidWorks, SolidEdge, Pro/E, Unigraphics, STEP, IGES, Parasolid, STL, and DXF, ensuring smooth integration with existing design workflows.

-

Customizable Machining Templates: Save frequently used machining strategies and setups to streamline repeat projects and ensure consistent results.

System Requirements

-

Operating System: Windows 10 or 11 (64-bit recommended)

-

Processor: Intel Core i7 / AMD Ryzen 7 or higher for optimal performance

-

RAM: Minimum 16 GB, recommended 32 GB for large projects

-

Graphics: Professional graphics cards (NVIDIA Quadro or AMD Radeon Pro) with updated drivers

-

Storage: At least 10 GB of free disk space, SSD recommended for faster load times

-

Additional Requirements: High-speed internet for software updates and license verification; optional 3D mouse for enhanced navigation

Bug Fixes & Performance Improvements

-

Resolved calculation errors during complex 5-axis machining operations.

-

Enhanced collision detection for multi-axis and multi-part setups.

-

Improved software stability, reducing crashes when simulating large or complex parts.

-

Optimized memory management for faster loading, rendering, and project switching.

-

Improved high-speed machining strategies to maintain surface finish quality while reducing machining time.

Benefits of WorkNC 2025

-

Maximize machining efficiency with intelligent automation.

-

Minimize errors and tool wear with advanced collision and toolpath optimization.

-

Reduce setup and programming time, allowing faster production cycles.

-

Achieve high-precision results for complex geometries in demanding industries.

-

Compatible with most industry-standard CAD systems, making integration seamless.

WorkNC 2025 is the ideal CAD/CAM software for manufacturers, mold makers, and CNC programmers seeking a reliable, high-performance solution for 2- to 5-axis machining. Whether producing automotive components, aerospace parts, molds, dies, medical devices, or dental prosthetics, WorkNC 2025 ensures precision, safety, and efficiency while reducing production time and costs.

⭐️⭐️⭐️⭐️⭐️5/5

“As a CNC programmer with over 10 years of experience in automotive and aerospace manufacturing, I have used multiple CAD/CAM solutions, and WorkNC 2025 stands out as one of the most powerful and reliable. The software’s advanced 2- to 5-axis machining capabilities, combined with intelligent toolpath automation, have significantly reduced my programming time and eliminated costly errors.

I particularly appreciate the high-speed machining strategies and multi-part machining features, which optimize efficiency while maintaining exceptional precision. Integration with major CAD formats like CATIA, SolidWorks, and STEP makes my workflow seamless, and the parallel processing feature drastically improves performance for complex projects.

The stability and collision detection improvements in this latest version give me confidence when working on intricate molds, dies, and aerospace components. WorkNC 2025 is a must-have for any professional CNC programmer seeking precision, efficiency, and reliability in high-demand manufacturing environments.”