CGTech VERICUT 9.4.0.4 fully cracked release

$ 170.00

VERICUT is the standard for CNC machine simulation for traditional milling and turning machines, additive hybrid machines, and composites. Companies, universities, trade schools, and government agencies of all sizes use VERICUT.

Description

New Module: CNC Machine Monitoring

CNC Machine monitoring allows you to live stream and monitor what your machines in the shop are doing, in real time, within VERICUT.

Check which NC program or subroutine is running

Monitor machine axis motions and spindle activity

Check if spindle or feedrate overrides are applied

See which tool is loaded and see active tool and work offsets

New Application: CNC Precheck

This new standalone app allows machinists to ensure that key aspects of the machine setup match what was verified in VERICUT, without checking out a VERICUT Verification license. Differences identified can then be investigated and resolved before running the machine and risking problems resulting from those differences.

Check that parameters from your physical machine and VERICUT’s virtual machine match

Verify that job setup information on the machine (NC programs, subprograms, work offsets, etc.) matches with corresponding VERICUT setups

Verify cutting tools and their length offsets match with VERICUT

VERICUT Tool Data has been expanded to include HSS and Ceramic cutters, as well as serrated edge types. With just one-click, the “Provide New Default Tool Data” feature provides industry standard cutting data for all Cutters (or Inserts) that can use VERICUT’s Stock Material Records. Default Tool Data for each cutter is specific to how that cutter size and type is used to machine the current stock material.

- Access built-in cutting data from well-known tool suppliers, for a variety of cutter types used to machine most common stock materials

- Verify that tools are being used within acceptable ranges

- Easily adjust tool data such as cutting limits and other values according to individual machining preferences

CNC Machine Connectivity

New Module: CNC Machine Monitoring

CNC Machine monitoring allows you to live stream and monitor what your machines in the shop are doing, in real time, within VERICUT.

- Check which NC program or subroutine is running

- Monitor machine axis motions and spindle activity

- Check if spindle or feedrate overrides are applied

- See which tool is loaded and see active tool and work offsets

New Application: CNC Precheck

This new standalone app allows machinists to ensure that key aspects of the machine setup match what was verified in VERICUT, without checking out a VERICUT Verification license. Differences identified can then be investigated and resolved before running the machine and risking problems resulting from those differences.

- Check that parameters from your physical machine and VERICUT’s virtual machine match

- Verify that job setup information on the machine (NC programs, subprograms, work offsets, etc.) matches with corresponding VERICUT setups

- Verify cutting tools and their length offsets match with VERICUT

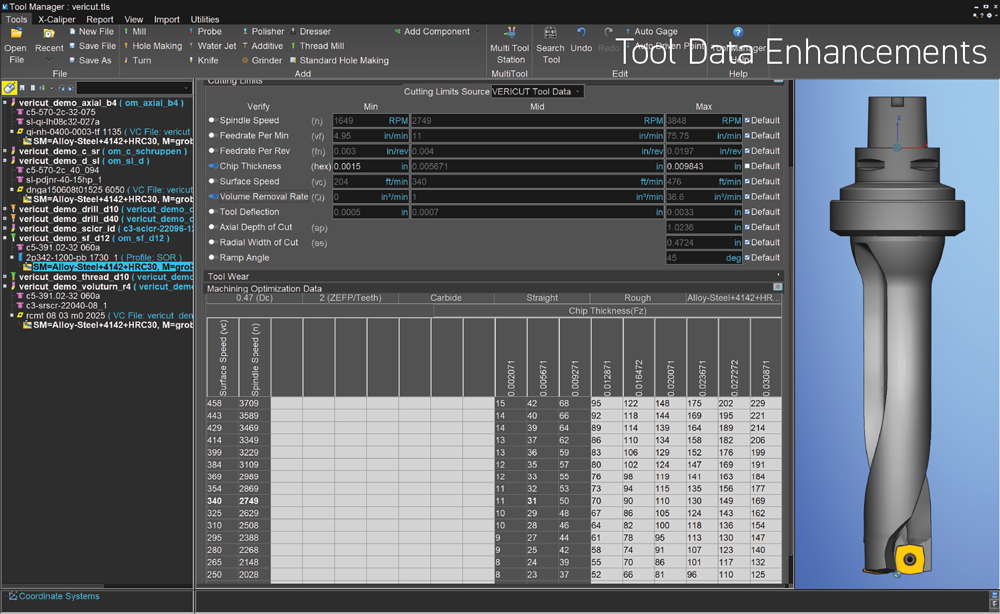

Tool Data Enhancements

VERICUT Tool Data has been expanded to include HSS and Ceramic cutters, as well as serrated edge types. With just one-click, the “Provide New Default Tool Data” feature provides industry standard cutting data for all Cutters (or Inserts) that can use VERICUT’s Stock Material Records. Default Tool Data for each cutter is specific to how that cutter size and type is used to machine the current stock material.

- Access built-in cutting data from well-known tool suppliers, for a variety of cutter types used to machine most common stock materials

- Verify that tools are being used within acceptable ranges

- Easily adjust tool data such as cutting limits and other values according to individual machining preferences

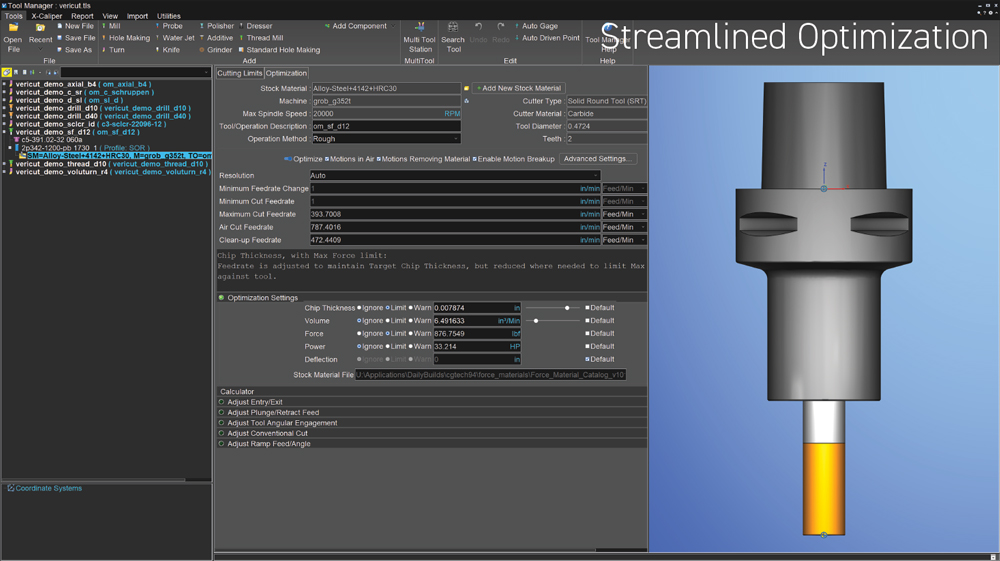

Streamlined Optimization

All VERICUT users, even those without the Force module, benefit from the enhancements to optimization in VERICUT 9.4. Streamlined setup and the settings provided by VERICUT Tool Data gives users an opportunity to quickly optimize their NC programs, without having to search for starting values when it comes to materials and cutting tool parameters. Users can also import cutting data with cutting tool assemblies, such as those from tool vendor sites and repositories like MachiningCloud, TDM, ZOLLER and more.

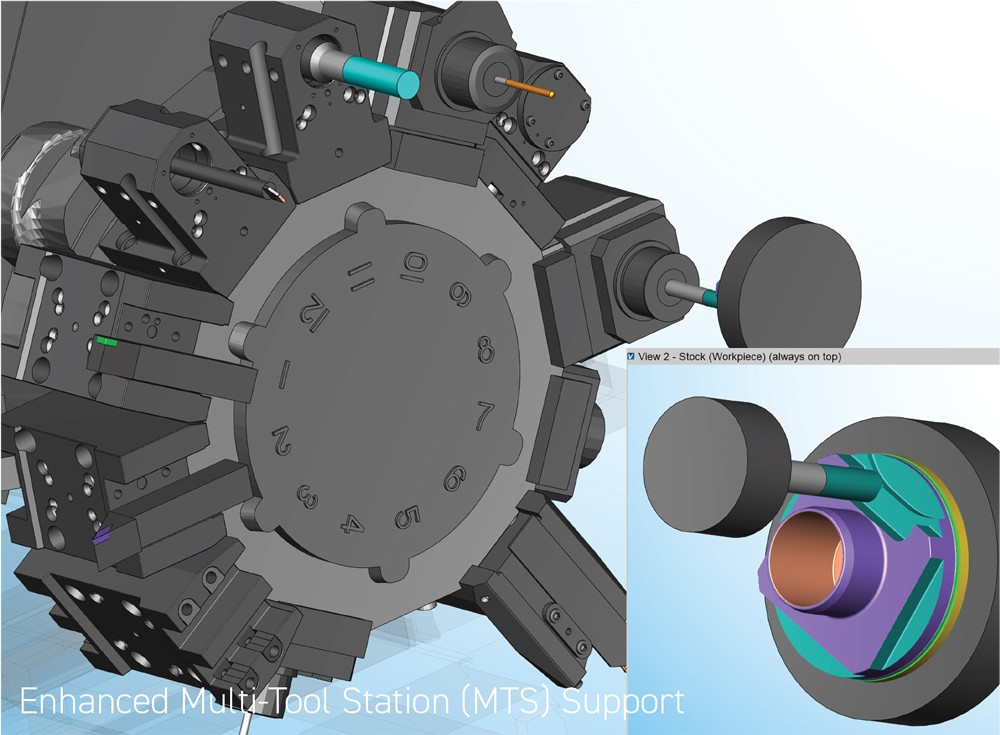

Enhanced Multi-Tool Station (MTS) Support

Enhanced support for NC programs and machines that utilize tools mounted in multi-tool stations (MTS). For each tool (known as a SubTool) mounted in an MTS, users can:

- Access cutting information and track machining metrics

- Simulate and optimize cutting

- Gather statistics for use in graphs

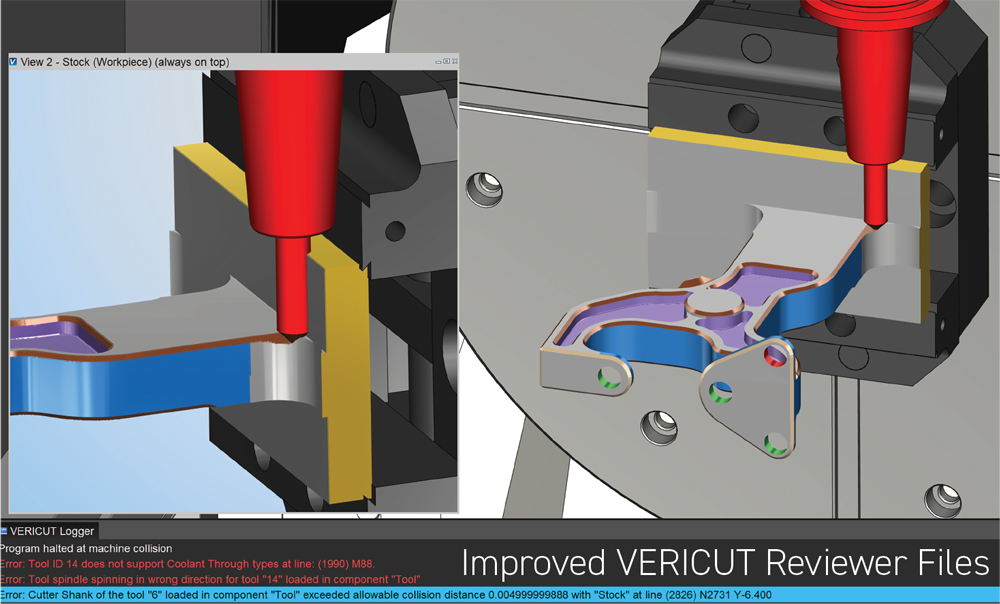

Improved VERICUT Reviewer Files

Machinists, Engineers, Quality Assurance and more can review NC programs prior to running them on the machine without tying up a VERICUT license using the free downloadable Reviewer App.

- Reviewer files have been reduced by 50% or more, for shorter load & save times, and easier transport to other departments

- New “Skip” option further reduces Review file sizes and increases playback speed for ease of use

- Measure part features and interrogate cuts to identify corresponding NC program, program line or codes, and cutting tool responsible for machining

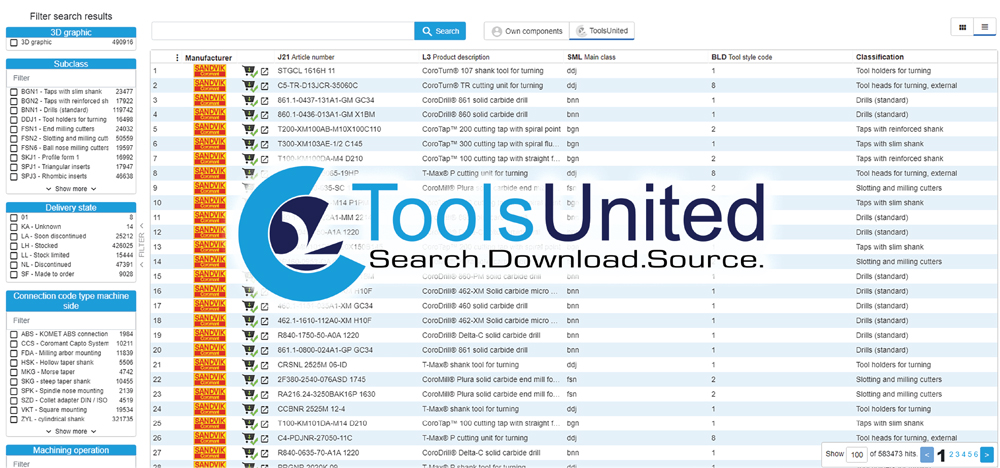

New ToolsUnited Interface

The new ToolsUnited interface is the most recent addition to VERICUT’s cutting tool connectivity options, and provides access to tool and cutting data from over 40 tooling vendors. VERICUT users can directly read 3D tool assemblies and their cutting data, and use them in VERICUT simulation and optimization.