HCL CAMWorks 2025 full cracked release

$ 170.00

HCL CAMWorks 2025 represents the newest version, a robust CAM software designed for CNC programming that seamlessly integrates with SOLIDWORKS, 3DEXPERIENCE SOLIDWORKS, and Solid Edge. This latest iteration introduces enhancements that directly address user feedback, thereby increasing the software’s capabilities and user-friendliness. Numerous improvements have been incorporated into CAMWorks 2025, further elevating its performance and efficiency…

Description

CAMWorks and SOLIDWORKS CAM, created by HCL, offer sophisticated CAD/CAM solutions designed to enhance programming efficiency and accelerate machining processes. These technologies include capabilities such as feature-based programming, automatic feature recognition, and knowledge-based machining, utilizing the TechDB to document and leverage your most effective practices.

Features

- Seamlessly integrated within 3DEXPERIENCE SOLIDWORKS or SOLIDWORKS desktop

- Feature-based machining

- True model associativity

- Knowledge-based machining

- High-speed machining strategies

Benefits

- Eliminates time-consuming CAM system rework due to design updates

- Eliminates hours of complex programming through Automatic Feature Recognition

- Automatically accommodates changes to the part model

- Automatically generates accurate toolpaths at the click of a button

- Increases machining productivity

CAMWorks for 3DEXPERIENCE SOLIDWORKS, CAMWorks for SOLIDWORKS desktop, and SOLIDWORKS CAM offer a comprehensive, integrated CAD/CAM solution tailored for machine shops of varying sizes. SOLIDWORKS CAM, which is powered by CAMWorks, is included with every subscription of SOLIDWORKS version 2018 and later. This software features 2.5 and 3-axis milling capabilities, with additional options for 5-axis simultaneous milling, mill-turn, wire EDM, nesting, simulation, and shop floor solutions available in higher tiers of SOLIDWORKS CAM and CAMWorks.

By utilizing a fully integrated CAD/CAM system, you can significantly reduce programming time, as there is no need to import or export CAD files into your CAM software. This integration allows for the storage of all part data in a single file, eliminating the need for separate CAD and CAM files. The software’s feature-based programming and automatic feature recognition enhance efficiency by leveraging CNC intelligence to identify necessary operations, tools, and feeds/speed rates. Furthermore, knowledge-based machining and the TechDB facilitate consistent, high-quality manufacturing by capturing and reapplying best practices. Tolerance-based machining further ensures superior tolerance and surface finish by interpreting MBD and PMI data to select appropriate machining strategies that align with specified tolerances.

CAMWorks for 3DEXPERIENCE SOLIDWORKS

- HCL CAMWorks has been officially authorized by Dassault Systèmes to develop, support, and promote add-ins for all SOLIDWORKS applications working with the cloud-based 3DEXPERIENCE platform

- HCL CAMWorks is seamlessly integrated with 3DEXPERIENCE SOLIDWORKS, facilitating the power of data management and cross-discipline collaboration in the cloud

- CAMWorks for 3DEXPERIENCE SOLIDWORKS is fully compatible with the CAMWorks and SOLIDWORKS CAM data from the SOLIDWORKS desktop version

Experience Better and Faster HCL CAMWorks

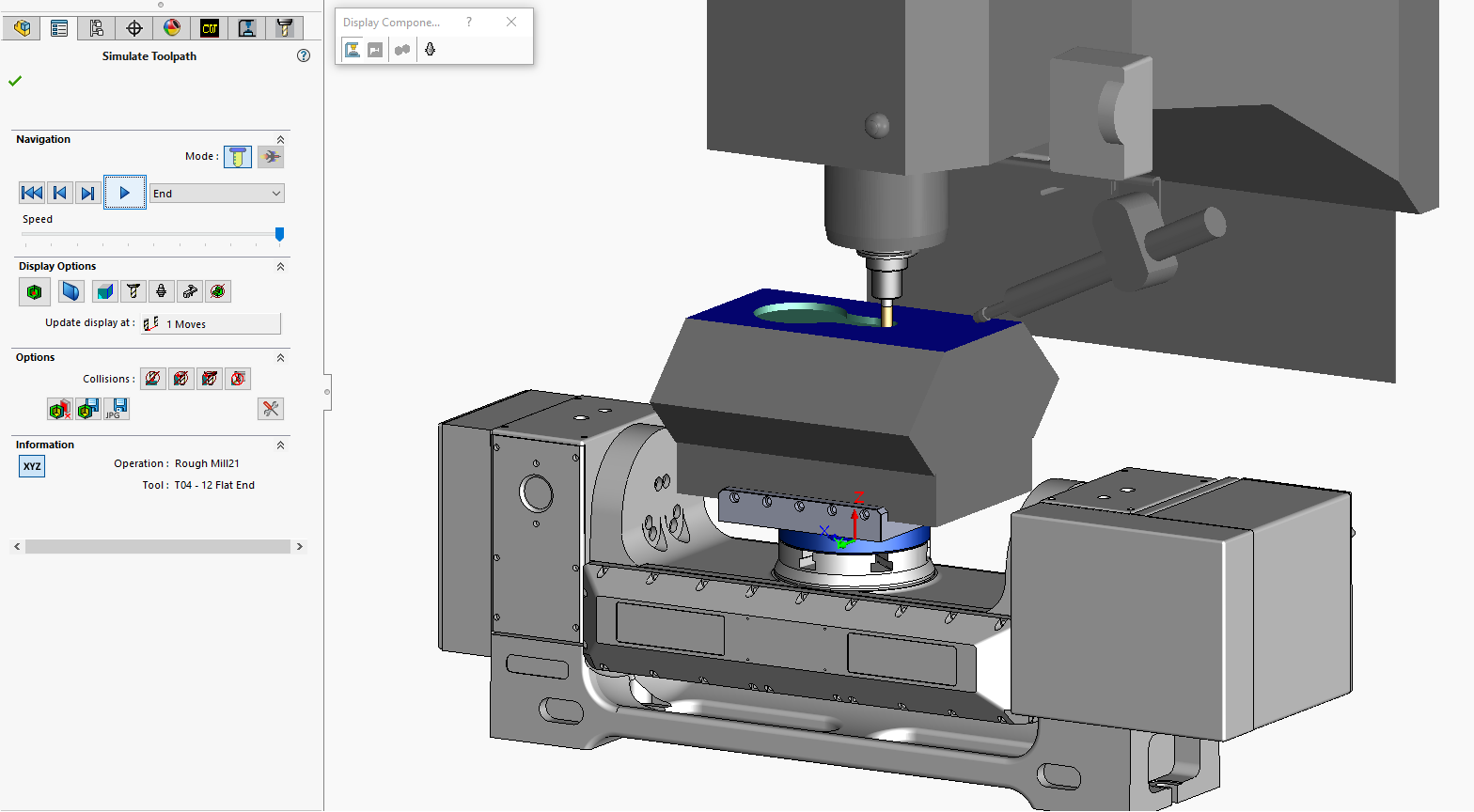

Machine Aware Programming Extended with Machine Components in Simulation

- Ability to display loaded turrets in full simulation as well as step through simulation

- Supports collision detection to prevent machine downtime and crashes

- Displays the spindle head in milling

- Includes the option to reset the customized simulation machine data in the Machine Definition dialog box back to the original state

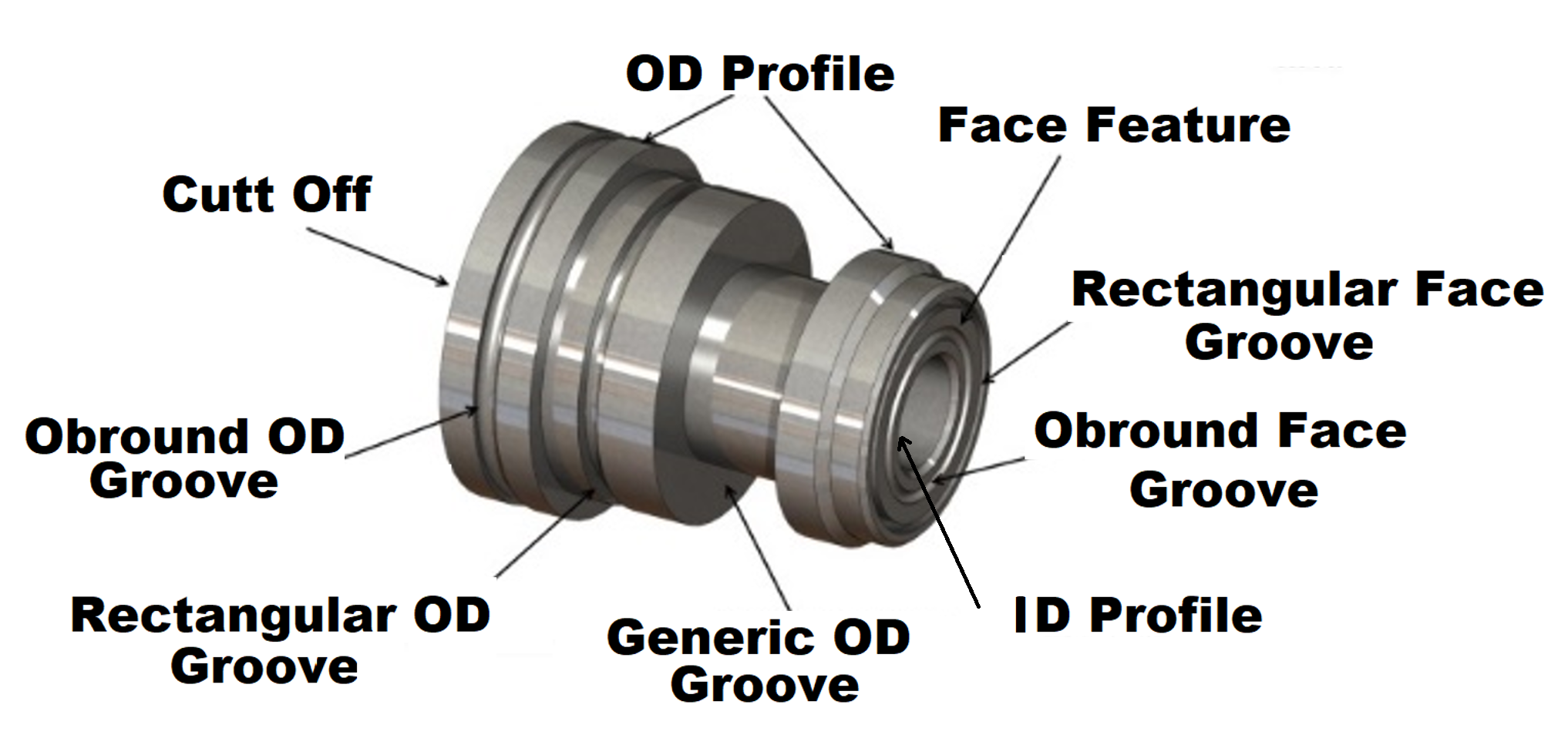

New Options for Automatic Feature Recognition of Turn Features

- Users can control which Turn features are to be recognized with Automatic Feature Recognition, saving time with part programming

- For example, a cutoff feature or face feature can be unchecked so that it is not included when Extract Machinable Features command is executed

- Cutoff feature has bar stock and other stock type options

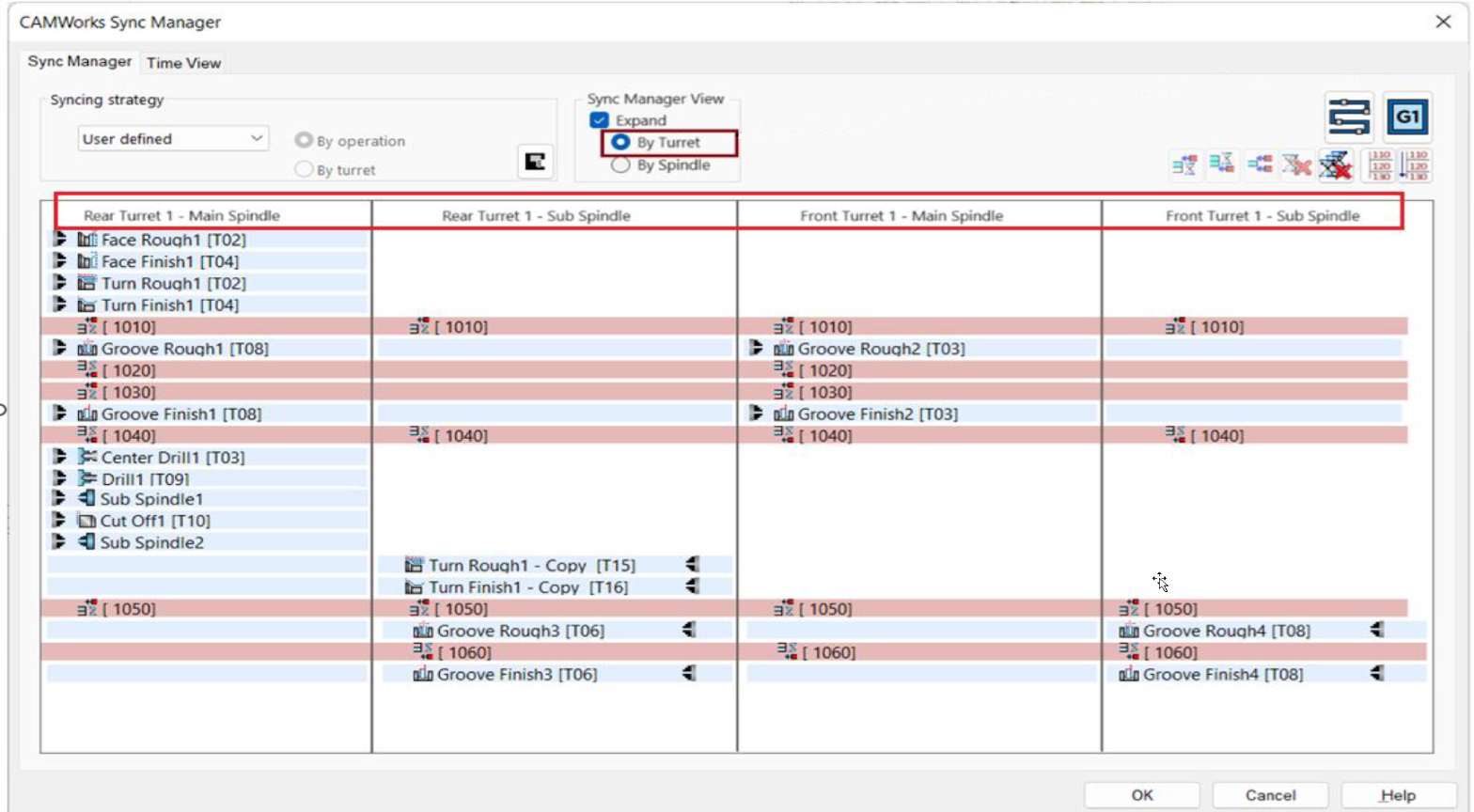

New Sync Manager Turret and Spindle Views

- An expanded view of the Sync Manager provides complete visualization of synchronized operations that includes turret and spindle data

- Enables users to visualize the synchronization of operations by sorting them into columns by the turret or by the spindle-turret combinations, assigned to the tools used for the operations

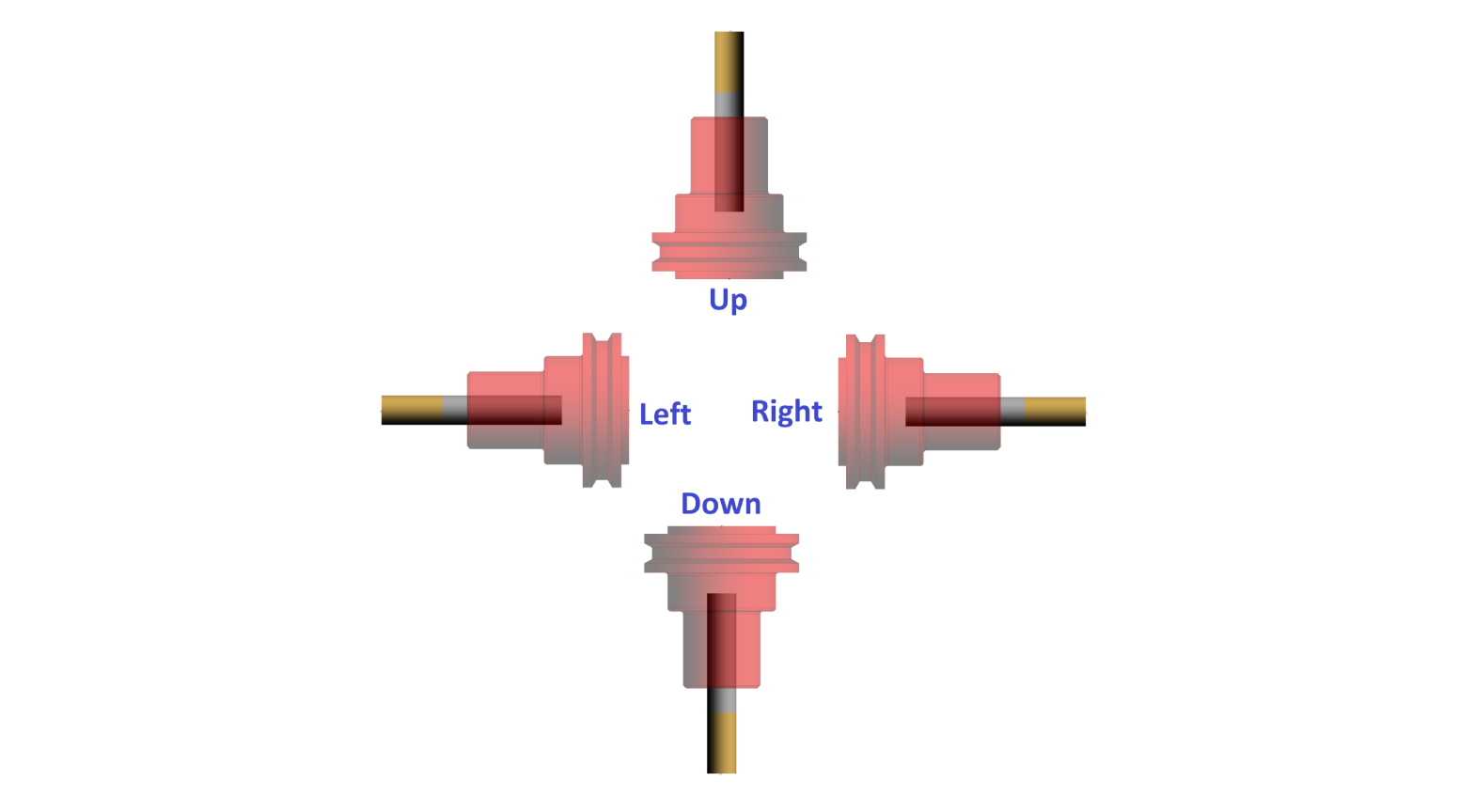

Defining Orientation for Milling Tools

- Ability to define the orientation of milling tools present in mill-turn tool cribs

- Allows unused tools to be shown in the correct orientation

- Options include left, down, right, up, and undefined

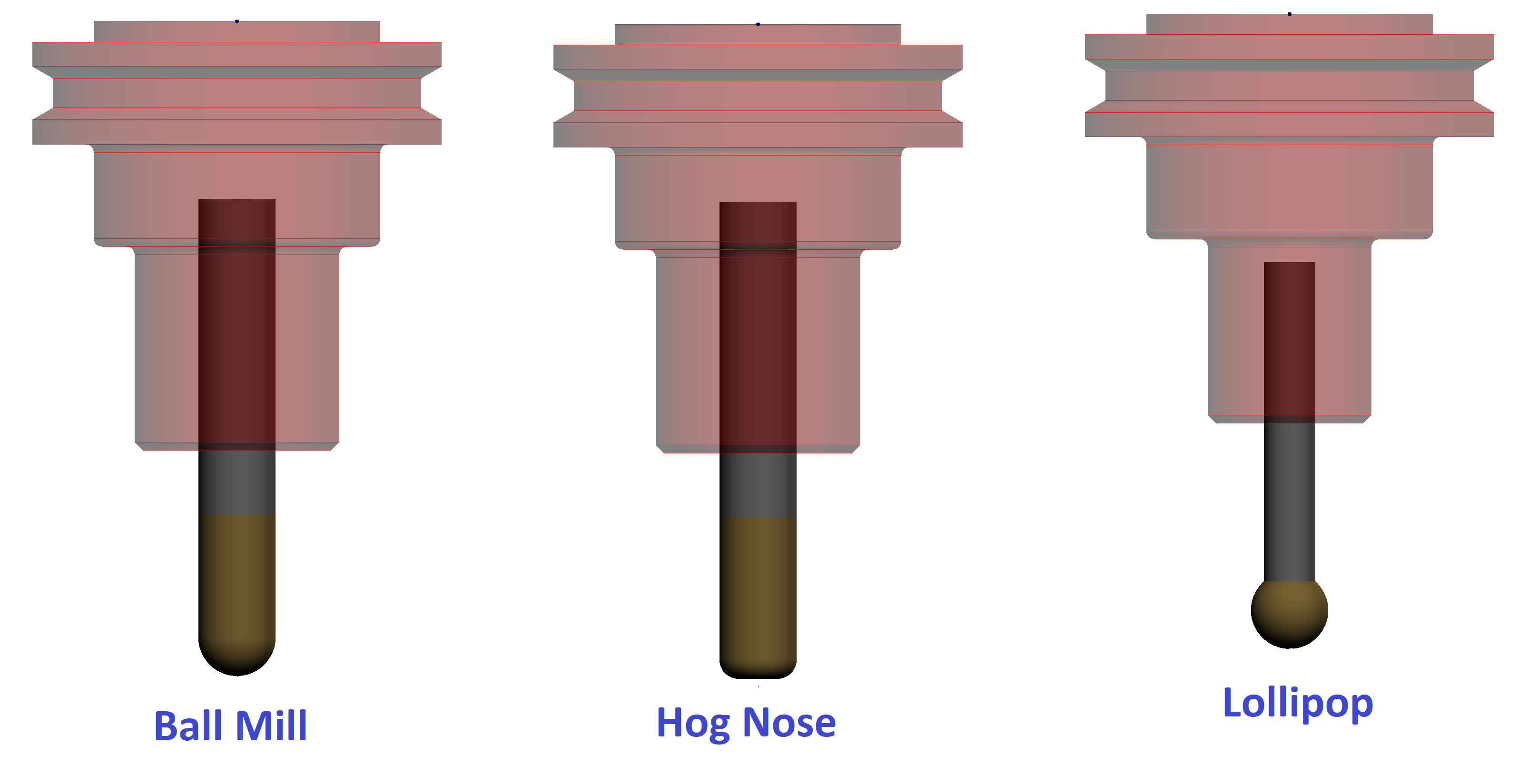

Additional Tools for Deburring and Chamfer Machining

- Option to select a Ball Nose, Hog Nose, or Lollipop tool for deburring and chamfer machining in contour milling operations

- Provides expanded tool options for users with these tool types

Collets as Work Holding Device

- Option to define a collet as the work holding device on a turn and mill-turn to machine a part model or assembly

- Users can assign a desired collet saved in the TechDB to the turn or mill-turn machine

- Collets are capable of producing a high clamping force and accurate alignment

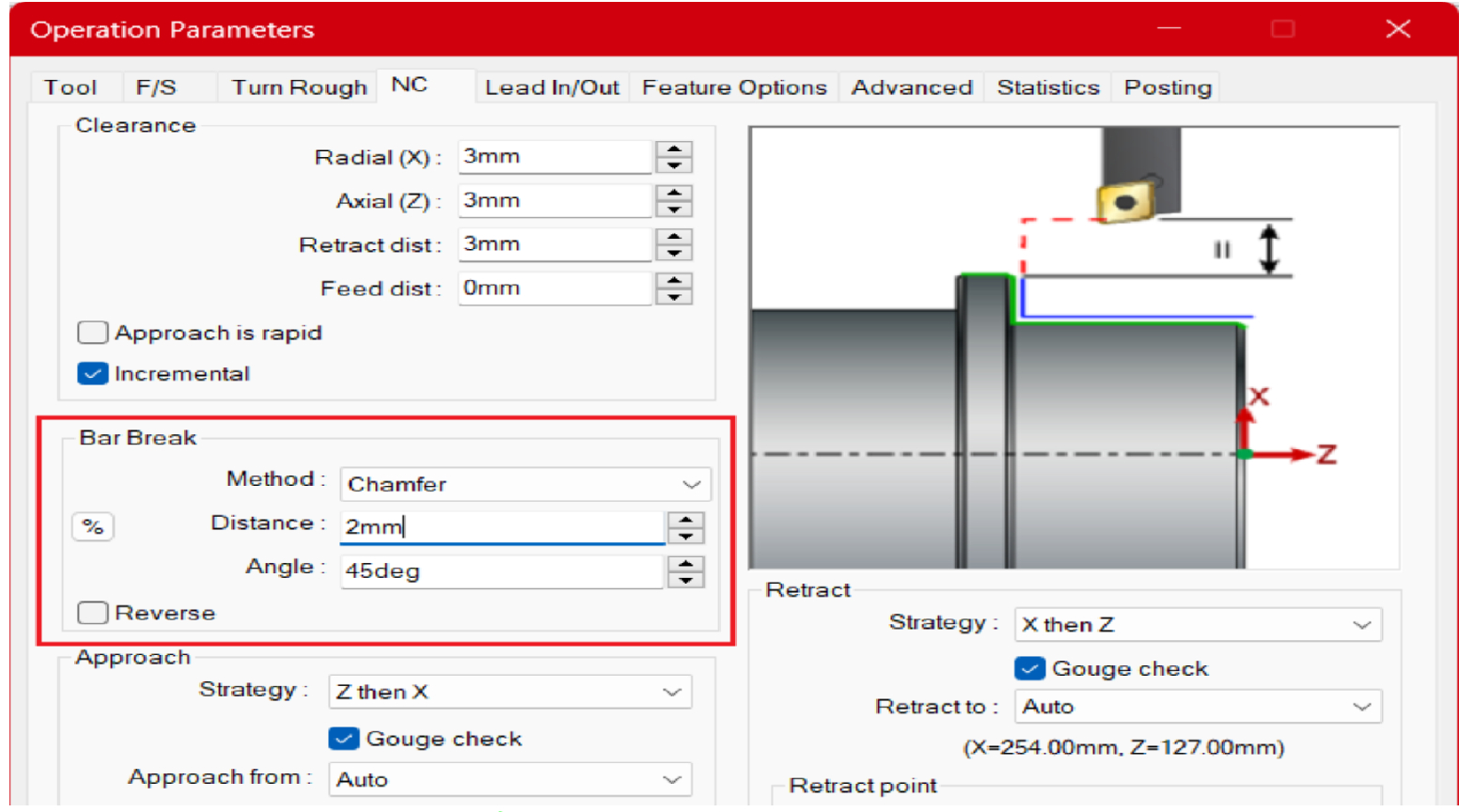

Bar Break Chamfering Option in Turn

- Support for bar break chamfering of the stock in turn toolpaths to prevent and eliminate burrs that can potentially damage machine components

- Option is available for turn roughing and finishing, groove roughing and finishing of OD feature, and face roughing and finishing

TechDB and Interface Enhancements

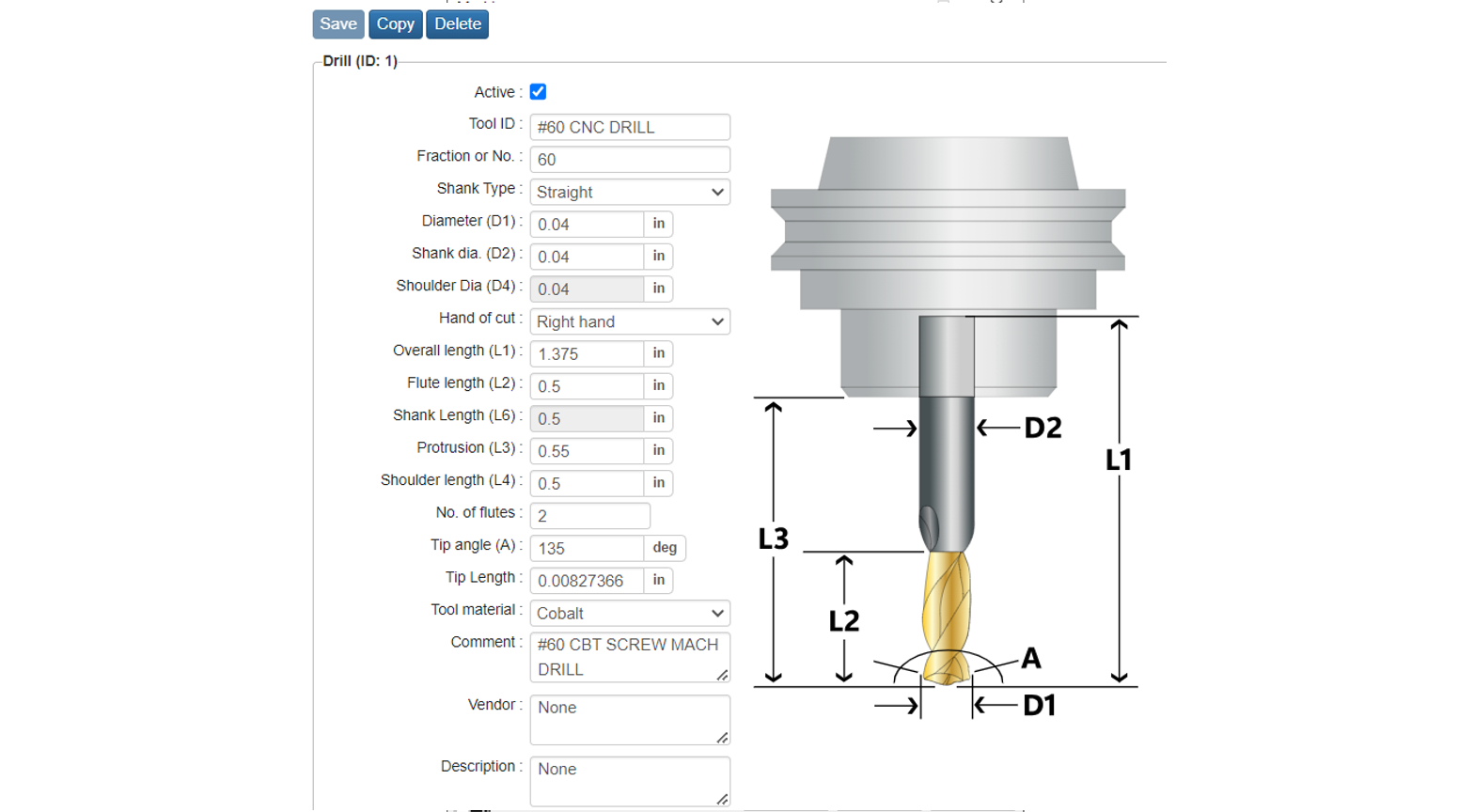

- Ability to highlight focused parameter dimensions in the tool image, making it easier to identify and read tool data

- Ability to resize the tool grid to make the tool image larger for ease of viewing