Camtek PEPS CAD/CAM System 2023 cracke release

$ 150.00

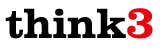

The PEPS suite of software is a Computer Aided Manufacturing (CAM) system based upon an integrated suite of software with facilities for designing geometrical models with its in-built CAD drawing tools or importing models from external CAD systems, and CNC part programming. The PEPS system takes a central part in fully integrated CAM installations, but is also ideally placed to provide an affordable solution to the CNC part programming needs of engineering businesses of all sizes.

Description

With over 40,000 installations and over 25 years of market presence, PEPS is one of the leading CAD/CAM systems. With its user-friendly Windows interface and intuitive user guidance, PEPS enables the user to work pleasantly, productively and successfully after a short training period. Due to the simple operation and the high degree of automation, even complex projects can be realised in a very short time with PEPS. Thus, the use of PEPS contributes to an increase in efficiency of your company after a short training period.

PEPS CAD/CAM systems are used in mould and tool making, mechanical engineering, contract manufacturing and CNC sheet metal working.

Due to its modular design, a PEPS CAD/CAM system can be configured in such a way that the requirements and wishes of the CAD/CAM programmer are taken into account in the system equipment.

In addition to the individual PEPS machining modules, there are numerous apic additional modules and PEPS add-on modules that make programming with the PEPS CAD/CAM system easier for the user.

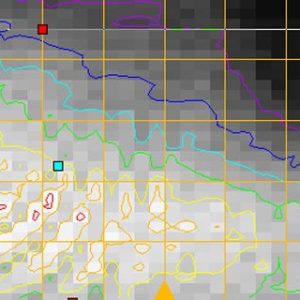

PEPS Wire EDM

Advanced CADCAM Software Solutions For The Manufacturing Industry

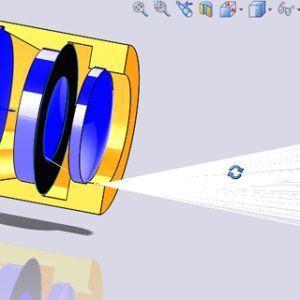

PEPS Wire is an industry leading Wire EDM CAD/CAM system developed specifically for the precision engineering, tool-making, mould & die, press and extrusion tool industries. It offers an intuitive environment for the comprehensive programming of all Wire EDM machines tools.

Features at a glance:

- Intuitive graphical user interface

- Extensive range of CAD interfaces; both for import and export

- Comprehensive machine and postprocessor database

- Feature recognition from solid models with projection onto cutting planes

- Roughing and finishing cuts easily applied to multiple punches / dies

- Variable land heights for extrusion dies and clipping tools

- Solid and Wireframe projection wizards

- Multiple tagging options with auto tag removal

- Reverse cutting with offsets and cutting technology changes

- Knowledge-based cutting schemes

- Multiple strategies for corner types; including square ISO and conic

- No-core pocket destruction of round and irregular shapes

- Full Solid 3D simulation, part sectioning and part comparison

- Option involute gear design module (for ISO / AGMA) and formed turning tool module available

PEPS Pentacut Laser

Advanced CADCAM Software Solutions For The Manufacturing Industry

PEPS Pentacut Laser is an industry leading 5 axis Laser CAD/CAM system developed specifically for the general engineering, automotive and aerospace industries. It offers an intuitive environment for the comprehensive programming of multi-axis laser or water-jet cutting machines.

Features at a glance:

- Intuitive graphical user interface

- Extensive range of CAD interfaces; both for import and export

- Comprehensive machine and postprocessor database

- Locate large parts with simplified part location system

- Automated Fixture Design

- ‘One-click’ application of toolpath for inner and outer profiles

- Manual application of toolpath for selected areas

- Edit cut technology and nozzle setting at unlimited positions

- Total control of nozzle angle; either interactively or explicitly

- Create and apply saved technology data at any point

- Inter- and Intra-cut collision detection

- Full Solid 3D simulation of machine, nozzle and part

PEPS Tubecut Laser

Advanced CADCAM Software Solutions For The Manufacturing Industry

PEPS Tubecut Laser is an industry leading Laser CAD/CAM system for rotary and multi axis cutting machines developed specifically for tube cutting and manipulation industry. The intuitive programming system allows tubes or sections to be parametrically defined from a library of standard shapes, which are then displayed as rendered solid images into which cutting apertures and profiles can be defined.