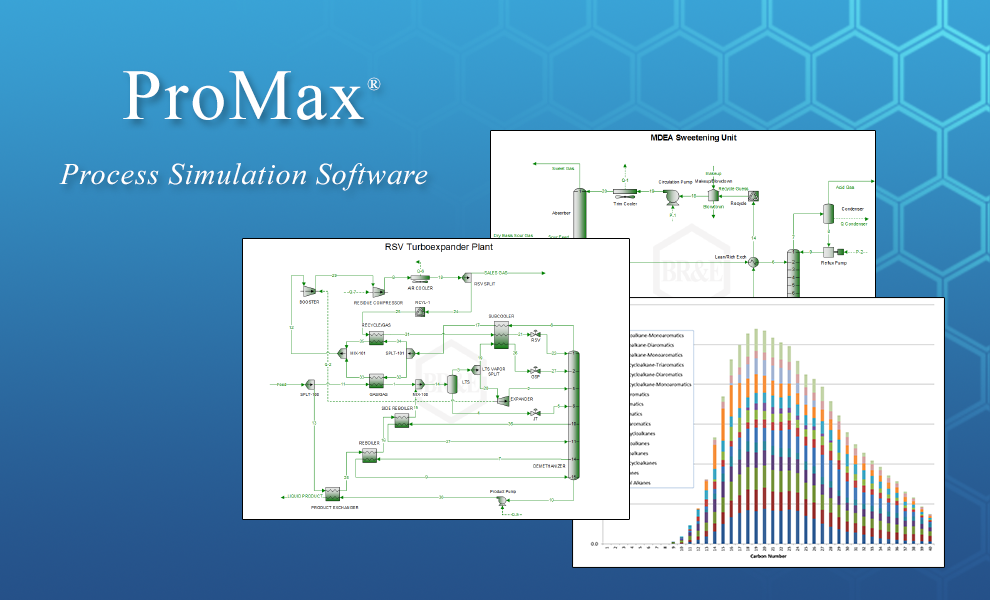

ProMax 6.0 full cracked version

$ 220.00

Together we can build a more sustainable future and help you reach your energy transition goals.

ProMax is a multifaceted process simulation software package that is made by engineers for engineers. It is designed to optimize gas processing, refining, and chemical facilities. With the newest version we have emphasized sustainable technologies such as green hydrogen, renewable natural gas, renewable diesel, and carbon-capture. The new Data Exchange feature allows read/write access to your historian to monitor your plant operations and calculate valuable performance information. Our goal is to support our clients in reducing emissions to help build a more sustainable future that will equip future generations to succeed…

Description

New Features in ProMax 6.0 Relative to ProMax 5.0

Data Exchange:

- The Data Exchange component allows ProMax to retrieve and store user selected content in the following external data sources: AVEVA PI, OPC-HDA, ODBC compatible databases, Microsoft Excel, and custom deployed solutions.

Optimization Tool™:

- The Optimization Tool allows users to create, solve, and analyze the solution of optimization problems. It automatically searches for a local minimum or maximum of a user-specified objective function by adjusting one or more user-defined variables. The objective function can be a ProMax property, value of a cell in Excel, or mathematical expression of one or more variables. Variables can be linked to ProMax properties or Excel cells. The Optimization Tool can be integrated with the Data Exchange feature to import from/export to data sources before/after each Optimization Tool run.

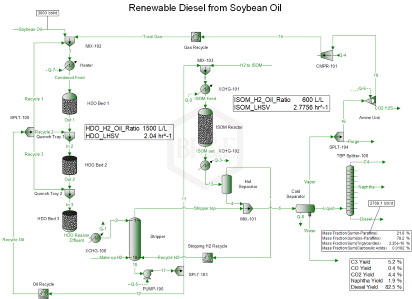

AutoKinetic Reactors:

- New reactions added to the Hydrotreating and Hydrocracking reaction sets: deoxygenation for triglycerides, carboxylic acids, and alcohols, methanation, water gas shift, and carbon monoxide adsorption to model biofuel production processes.

New Blocks/Unit Operations:

- AP-42 Tank Losses: The block allows users to calculate flashing, working, standing, and loading losses using EPA’s AP 42 equations. Air Emissions can also be calculated on a short-term basis using TCEQ’s equations.

- Water Electrolysis: The Water Electrolysis block simulates Hydrogen production based on water electrolysis technology and calculates the relationships between four important parameters: current density/overpotential, area of the membrane, hydrogen production, and the power required for the process. The block supports three different water electrolysis technologies:

- Polymer Electrolyte Membrane (PEM) Electrolysis

- Alkaline Water Electrolysis

- High-temperature Electrolysis (Solid Oxide)

- Relief Valve: Used to calculate relief scenarios.

- Adsorber block

Calculators:

- A new Quick Specifier and Quick Solver option has been added to simplify the creation of Specifiers and Solvers that only involve a single variable. The Quick Specifier provides a linear relationship with a single variable. The Quick Solver drives a single variable to a setpoint. Neither require creation of a script.

Distillation Column:

- Multiple draws can be added to a stage for a single phase.

- A new option to display either the minimum or maximum value of any chosen property has been added for column specifications that are stage based: phase property, phase composition, hardware property, and mass transfer property (when applicable). ProMax will display both the value of the selected property as well as the stage where the minimum or maximum is found in the specifications tab of the column.

- Liquid-liquid columns now report the following hydraulic properties:

- General: Diameter, fraction flooding, and liquid load

- Sieve tray: Fraction active area, weir side width, and tray pressure drop

- Random/Structured packing: Dispersed phase holdup

- Calculates the mass of the column given the wall thickness or the maximum allowable working pressure of the vessel, including the mass of the internals.

- Raschig packings are available for hydraulic and mass transfer calculations.

- Offers a flooding, holdup and pressure drop correlation from Raschig for Raschig random and structured packings.

- Provides many new sizes and types of Raschig packing.

- Includes a new ‘Raschig’ option for mass transfer correlation.

- Added MellapakPlus 352.Y and Intalox Ultra T, A, L, X packings.

- Updated the KGPackCalc packing calculation module from Koch-Glitsch.

- Mass + Heat Transfer columns now give the column partial pressure driving force and approach to equilibrium for all components and stages.

Sulfur Plant Reactors:

- A new Gibb’s set “Claus Furnace Flame Zone” has been added. Additionally, the reactor block now has the option to select a built-in reaction set to simulate: “Claus Furnace Anoxic Zone”, “Claus Converter”, and “Hydrolyzing Claus Converter”.

- The “Claus Furnace Flame Zone” Gibb’s set, together with the “Claus Furnace Anoxic Zone” built-in reaction set, are used to model the front-end furnace of Claus units.

- The “Claus Furnace Flame Zone” Gibb’s set comes with a default constraint for CS2 formation, as well as additional constraints for CO, H2, Benzene, Toluene, and p-Xylene that may be added. COS and NH3 are left unreactive in the Flame Zone, as they are handled by the Anoxic Zone reactions.

- The “Claus Furnace Anoxic Zone” built-in reaction set contains kinetic parameters and reactions for CS2 destruction, COS formation/destruction, NH3 destruction, and other reactions that occur in the Claus furnace.

- The “Claus Converter” and “Hydrolyzing Claus Converter” model the catalytic beds of the Claus unit and they contain different sets of kinetic parameters for the Claus and hydrolyzing reactions.

- Kinetic parameters and catalyst activity for the built-in reaction sets may be adjusted in the new ‘Parameters’ tab of the reactor.

Environment and Property Packages:

- New solvent based liquid phases are present in both stream views and external physical property requests complement the original density-based phases. This extends the number of possible distinct coexisting liquid phases to any combination of three preset phases (Aqueous, Sulfur and Mercury phases), two customizable and one nonspecific phase.

- Added EOS-LNG

- Eastman AdapT solvents have been added.

- The following UCARSOL™ solvents have been added:

- HS-101, HS-102, HS-115

- AP-802

- LE-713, LE-777, LE-801

- COS reactive absorption in amines has been added.

- Glycine and sarcosine are now dissociating, CO2-reactive amino acids.

- Bicine, L-proline, thiocyanic acid, oxalic acid, and glycolic acid are now dissociating compounds.

- DEEA (N,N-Diethylethanolamine) and DMEA (N,N-Dimethylethanolamine) are now dissociating, CO2-reactive amines.

- Improved properties of DIPA-Ox degradation products.

- Added the following triglycerides: tripalmitin, trilinolein, trilinolenin, tristearin.

- Added a typical plant-oil mixed species.

- The prediction of viscosity of high piperazine concentration solutions has been improved.

Pipeline:

- New Multiphase Flow Correlations have been added in the Line Sizing Analysis and Pipeline:

- TUFFP Unified and TUFFP Vapor-Liquid mechanistic models.

- Petalas and Aziz mechanistic model for vapor-liquid flow.

- Hagedorn-Brown is an empirical correlation for upward vertical or nearly vertical vapor-liquid flow.

- Homogeneous is a no-slip model which assumes that the gas and liquid travel at the same velocity.

- Flow Regime Map plots are now available.

Project Connection Tool:

- The Project Connection Tool provides an interface for controlling and connecting multiple ProMax projects. Multiple ProMax files can be opened, solved, connected, and manipulated, all from a common interface. This allows for the connection and control of multiple ProMax projects, while keeping them saved in separate files.

PVT Tool:

- The PVT Tool allows users to simulate a laboratory Pressure-Volume-Temperature (PVT) study on a gas or oil reservoir fluid, and display the results in a formatted, customizable Excel-based report. Given the composition of a reservoir fluid from a bottomhole sample or the compositions of the gas and oil streams from a 1st stage production separator with a recombination gas-oil ratio, the PVT Tool can model the analyses performed in a standard PVT study. It can calculate and output key PVT study parameters within minutes, whereas a laboratory PVT study can take several days and significant monetary cost to perform.