hyperMILL 2025 by OPEN MIND + update3

$ 180.00

hyperMILL 2025 by OPEN MIND – advanced CAM software for high-precision 5-axis machining, automated deburring, and optimized toolpaths. Boost CNC efficiency today!

Description

hyperMILL 2025 by OPEN MIND – The Next Evolution in Intelligent CAM Software

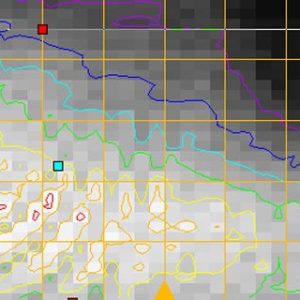

hyperMILL® 2025 from OPEN MIND Technologies is the newest generation of high-end CAM (Computer-Aided Manufacturing) software, delivering powerful new tools and intelligent automation for optimized CNC machining. Tailored for advanced 3-axis to 5-axis milling, turning, mill-turn, and hybrid manufacturing environments, hyperMILL 2025 significantly boosts programming speed, machining accuracy, and production flexibility.

Ideal for industries including aerospace, automotive, mold & die, medical device manufacturing, and precision engineering, this release represents a major leap forward in toolpath innovation, surface quality, and CAM automation.

🆕 What’s New in hyperMILL 2025?

hyperMILL 2025 introduces several game-changing enhancements that bring greater performance and automation to your CAM environment:

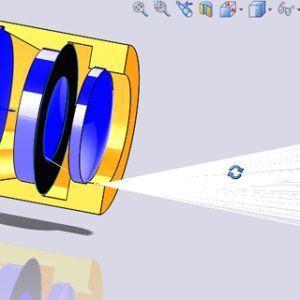

🔹 1. Automatic 5-Axis Tool Orientation

This intelligent feature pre-analyzes the full machining job and identifies where indexed or simultaneous 5-axis movement is most effective. The result is a smarter, safer, and more efficient toolpath—automatically generated with fewer collisions and smoother transitions.

🔹 2. Comprehensive 5-Axis Deburring Strategies

Three new deburring strategies, including one tailored for holes and hole intersections, ensure fully automated edge finishing. hyperMILL automatically detects sharp edges and applies precise tool movements to remove burrs on complex 3D and 5-axis geometries.

🔹 3. Dynamic Stock Model Technology

Real-time, continuously updated stock models are now integrated across all machining operations. This ensures optimal toolpath linking, avoids unnecessary air cuts, and minimizes cycle times—especially effective in rest machining and rework scenarios.

🔹 4. New 5-Axis ISO Surface Machining Cycle

This new function allows machining along defined ISO surface curves (U and V directions), delivering unmatched control over finishing strategies for complex surface topologies. Perfect for high-precision mold and aerospace part production.

🔹 5. Revised 5-Axis Profile Milling Cycle

With an updated algorithm, this cycle supports faster programming and more accurate results. New options for lead angle, contact point control, and collision avoidance make it a must-have for high-quality part finishing.

🖥️ New and Improved CAD Functions

hyperMILL 2025 isn’t just a CAM upgrade—it also boosts CAD functionality with modernized workflows and speed enhancements:

-

Advanced Tessellation Algorithm: Enhances model loading and viewing performance, especially with large STL files or complex solid models. This improves efficiency across the design-to-manufacturing pipeline.

-

Redesigned Linear Sweep Function: Create inclined surfaces with automatic trimming and boundary control. Ideal for mold design, electrodes, and multi-surface extrusion.

-

Layer Visibility Performance Boost: The new “Switch all layers to non-selectable” feature dramatically improves performance when opening large assemblies or importing heavy geometry data.

⭐⭐⭐⭐⭐5/5

“Super impressed with hyperMILL 2025! The new 5-axis tool orientation and deburring features save me a ton of time on complex parts. Stock model tracking is spot on, and the updated CAD performance is noticeably faster. Perfect for high-precision CNC work—absolutely worth the upgrade!”— Alex D., CNC Programmer

💡 Key Benefits of Upgrading to hyperMILL 2025

-

Drastically reduced programming and machining times

-

Enhanced 5-axis automation and collision avoidance

-

Improved surface finishes and precision machining

-

Greater control over toolpaths with dynamic stock-aware linking

-

Better performance with large CAD assemblies

-

Seamless integration with leading CAD platforms

-

Fewer manual edits with intelligent automation and edge detection

-

More reliable post-processing for machine-specific optimization

⚙️ System Requirements

Ensure optimal performance with the following recommended setup:

-

Operating System: Windows 10 (64-bit), Windows 11 (64-bit)

-

CPU: Multi-core processor (64-bit architecture), Intel i7/i9 or AMD Ryzen recommended

-

Memory (RAM): 16 GB minimum, 32 GB or more recommended

-

Graphics Card: OpenGL-compatible GPU with 4 GB dedicated memory (NVIDIA Quadro or RTX preferred)

-

Hard Disk Space: 50 GB free space minimum for installation

-

Display Resolution: 1920×1080 minimum (4K supported)

-

Supported CAD Integrations:

-

Autodesk® Inventor® 2023–2025

-

SOLIDWORKS® 2023–2025

-

OPEN MIND hyperCAD®-S

-

🛠️ Bug Fixes and Performance Enhancements

hyperMILL 2025 includes multiple stability, reliability, and performance improvements, such as:

-

Improved robustness in 5-axis collision checks

-

Corrected simulation discrepancies in complex milling cycles

-

Faster load times and reduced memory usage for large model files

-

Stability fixes for tool database import/export operations

-

Enhanced compatibility with the latest postprocessor frameworks

-

Eliminated rare crashes during dynamic stock calculations

💬 Why Choose hyperMILL 2025?

Trusted by world-class manufacturers, hyperMILL 2025 combines precision, automation, and flexibility in one powerful CAM platform. Whether you’re aiming to reduce machining time, eliminate rework, or handle increasingly complex part geometries, hyperMILL gives you the tools to stay ahead of the competition.

Get hyperMILL 2025 today and experience next-generation CAM technology built for the future of smart manufacturing.

➡️ Order now and take full control of your CNC processes with hyperMILL’s intelligent automation and unmatched precision.