ICAM CAM-POST NC Post-Processing Solution V18 cracked

$ 185.00

CAM-POST is an advanced independent single source NC post-processing development, management and deployment technology supporting all major CAD / CAM / PLM systems, CNC controllers and machine tools.

CAM-POST incorporates over 35 years of industry leading NC expertise to deliver the most advanced, intuitive and flexible system architecture available.

Description

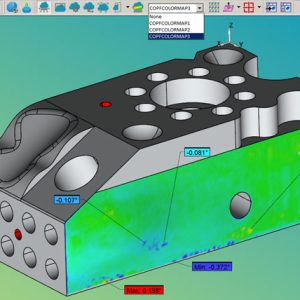

Advanced Post-Processing & Multi-Axes Specialization

Embedded CNC optimization technology delivers improvements to part quality, production output and reduced cycle time – the real measure of a post-processor can be taken from the quality of NC Code it produces. Several of CAM-POST® most powerful standard features, providing the user with on-demand access to advanced functionalities in the multi-axes machining world, are outlined below.

Advanced linearization… provides the user with controls at the tool tip as well as tool wobble (angular) controls. Linearization can be performed based on the expected tool gauge length. The user can optionally linearize RAPID motions as well.

Rotary-turn-around (RTA)… is logic that can retract a tool from the material and reset to the alternate pose when rotary or linear travel is exhausted during continuous machining. Rotary axis winding and pre-positioning features provide extended uninterrupted 5D cutting. Preferred rotary positioning can be used to ensure better operator visibility or to enforce a consistent 5-axes pose where possible.

Path planning… uses look-ahead to automatically select the best path during the rapid positioning motion, to avoid the requirement for rotary-turn-around if possible. Path planning also prepositions rotary axes that are parallel to the tool if it discovers that they must be rotated midway through a continuous cut.

Rotating Tool Center Point (RTCP)… is a feature of advanced controllers that permit the user to output tool tip coordinates instead of control point coordinates. RTCP programming supports actual axes, vector, dual point, Euler, RPY or virtual axes rotary control methods. The control computes the kinematics and handles linearization, with the benefit of simpler and more transportable programs, as well as full 5D tool compensation.

Local Coordinate Frame Transformation (LCS)… CAM-POST supports translation, rotation, scale, mirror and additive transformations. Activation of coordinate frames can be set automatically, whenever the tool orientation changes, or can be set on demand. LCS also includes recognition of preferred coordinate frame hints from the CAM system. All travel, feed and timing calculations continue to be based on the true physical configuration of the machine.

CAM-POST® V18 offers an array of new features to its end-users including:

- Rotary head support for 5-axes Mill / Turn machines

- New polar interpolation (TRANSMIT, G12.1…) & emulation support for Mill/Turn & Mill machines

- Rotary axis “singular positioning” optimization to avoid linear axis over-traveling conditions

- Automatic switching between Cartesian (xyz) and Polar (zxc) to avoid linear axis over-traveling

Technical Specifications

CNC Machine Tools

All classes of CNC equipment supporting any combination of rotary heads and/or rotary tables: Mills, Lathes, Horizontal/Vertical Machining Centers, Merging Lathes, Multi-Tasking Mill/Turns, Punch Presses, Wire EDMs, Water Jet Cutting Machines, Laser Cutting Machines, Plasma & Flame Cutters, Hybrid and Special CNCs.

CAD/CAM/PLM Systems

CATIA V4, CATIA V5, PLM Software (NX), PRO ENGINEERING, MASTERCAM, CADDS 5 NC, CIMATRON, DUCT, GIBBSCAM (APT), I-DEAS MASTER SERIES, NCL, OPEN MIND HYPER MILL (APT), POWERMILL, SURFCAM, WORK NC.

APT Processors: CAM-APT-SURF, HMS-APT, APT-AC, EX-APT, WS-APT

CAM-POST Advanced Features |

|

|

|

Computer hardware platforms: Hewlett-Packard Inc, HP9000 (HP-UX), International Business Machines Corp (AIX), Sun Microsystems (Solaris 2), Windows XP / 2003 / Vista

Industrial Sectors: Aerospace. Mechanical Parts Manufacturing, Electronics, Automotive, Research, Defense, Education, Machine Tool Manufacturing, Chemical, Mold Making, Heavy Equipment Manufacturing, Furniture, Construction , etc.

CAM-POST Benefit Highlights

Ease of use takes the front seat for a quick & efficient implementation…

CAM-POST includes over 200 NC controller quick-start defaults, which can be selected to simplify and speed post-processor creation. Also, as a standard feature, CAM-POST includes a unique comprehensive “point and click” Wizard that allows even the most novice users to generate advanced NC post-processors quickly and effectively.

The Wizard easily guides users through all the various steps involved when creating NC post-processors by using illustrated sets of instructions, which provide an intuitive graphical interface for effortless definition of machine kinematics, axis sign conventions, travel limitations and rotary pivot distance offsets.

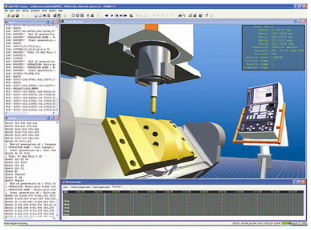

Virtual Machine® for Integrated machine tool simulation during post-processing…

Implementing Virtual Machine as an integrated option to CAM-POST, delivers a powerful graphical machine tool simulation solution that enables NC programmers to graphically simulate and test programs against collisions easily and automatically during post-processing.

The machine tool and controller data for both Virtual Machine and CAM-POST are stored and managed in the same database. This eliminates the error-prone and time consuming alternative of entering the same machine and control data twice when using a non-integrated solution .

An instinctive, knowledge-based methodology…

CAM-POST provides a “Navigator” that organizes post development into broad categories and more specialized subcategories. A “Modification Wizard” provides access to a subset of the complete development environment, exposing only those post-processor specifications most likely to require review. CAM-POST’s extended depth enables customers to handle complex situations by providing simple responses, rather than having to design and develop logic using macros.

Increased NC Programmer productivity and manufacturing process efficiency…

The CAM-POST “Visual Debugger” traces and synchronizes the CL file input, NC code output, macro code and diagnostic messages produced during post-processing. The user can view or change any post-processor variable on the fly, in a single integrated workbench. Breakpoints can be set and cleared with the mouse pointer on CL records, macro source, when variables change or when certain blocks are output.

CAM-POST management capabilities include: full do/undo to support for multiple revisions of the post-processor to compare different post versions with “links” to directly jump to differing post specifications; full-time on-line help and a “quick test” button to immediately see the NC code effect on changes for easy experimentation.