SPACE-E v5.11R2 cracked release

$ 150.00

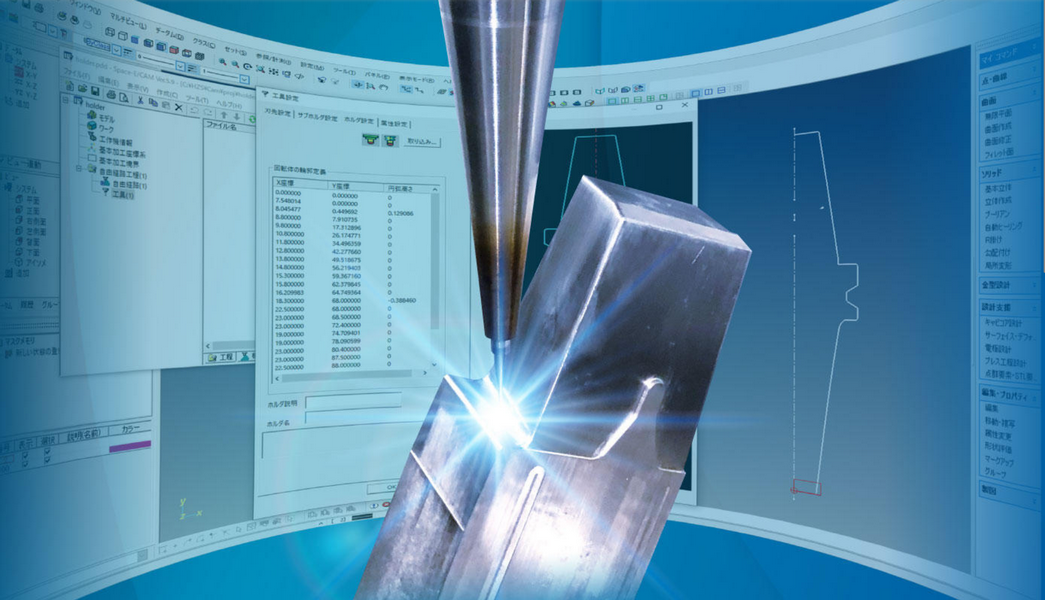

Space-E is a renowned mold design and processing system, particularly tailored for mold manufacturing companies. It excels in both surface modeling and solid modeling, offering robust editing capabilities that enable seamless mixed modeling between solids and surfaces. The software can generate variable radius guide corners on solid and surface prisms, enhancing design flexibility…

Description

A standout feature of Space-E is its auto-guidance function, which automatically cuts and creates smooth halo corners at intersections, significantly accelerating the modeling process. Additionally, the software includes advanced tools such as automatic stitching and boundary replacement between surface boundaries. These features are designed to rectify errors arising from surface generation, editing, and graphic conversion, ensuring that the final geometry is uniform, smooth, and free of gaps. This precision is highly beneficial for parting operations and improves overall processing accuracy, making Space-E an indispensable tool for mold design and manufacturing.

Space-E offers advanced mold design capabilities, including specialized tools for extracting shells from solids with varying wall thicknesses, enabling efficient cavity molding. These features empower mold designers to achieve higher precision and productivity by streamlining complex workflows, reducing manual effort, and minimizing errors. With its focus on parametric modeling and automated corrections, Space-E ensures seamless integration of solids and surfaces, making it a critical solution for optimizing mold design accuracy and efficiency in industrial applications.

Space-E Software: Advanced Mold Design & Manufacturing Solution

Space-E is a leading mold design and manufacturing software renowned for its robust capabilities in precision engineering and industrial efficiency. Its key features include:

1. Advanced Surface & Solid Modeling

Space-E excels in hybrid modeling, seamlessly integrating solids and surfaces to create complex geometries. Key tools include:

- Variable Radius Guide Corners: Generate smooth, radius-variable edges on solid and surface prisms.

- Auto-Guidance Function: Automatically cuts intersections and creates flawlessly blended halo surfaces, accelerating modeling workflows.

- Automatic Stitching & Boundary Replacement: Corrects gaps or errors from surface generation, editing, or file conversion, ensuring uniform, gap-free geometries. This precision enhances parting operations and machining accuracy.

2. High-Precision Digital Approximation Calculations

Space-E employs proprietary digital approximation equations to refine solid and surface accuracy, critical for high-speed machining. This technology eliminates defects like surface checkering caused by poor geometric fidelity, ensuring superior mold finish and durability.

3. Comprehensive Functional Modules

Beyond core modeling, Space-E offers integrated tools for:

- Engineering Drawing Generation: Streamlines documentation.

- Plastic Mold Design: Specialized features for injection molds.

- CNC Machining: Optimized toolpaths for precision manufacturing.

The software’s surface modeling and CNC modules include unique capabilities tailored to complex mold design requirements.

4. Broad Software Compatibility

Space-E supports seamless integration with leading CAD platforms (e.g., Autodesk Inventor, Pro/ENGINEER, SolidWorks) and enables direct conversion of CAD/CAE models for finite element analysis (FEA). This interoperability simplifies data exchange, enhances collaboration, and reduces workflow bottlenecks.

Why Choose Space-E?

Space-E is widely recognized in the mold industry for its:

- Hybrid Modeling Flexibility: Combines solids and surfaces for intricate designs.

- Precision Engineering: Unique algorithms for high-accuracy machining.

- End-to-End Workflows: From design to CNC-ready outputs.

- Cross-Platform Compatibility: Effortless integration with industry-standard tools.

Ideal for mold manufacturers and designers, Space-E drives innovation by streamlining complex processes, minimizing errors, and delivering industry-leading results.