Mastercam 2024 Perpetual License cracked

$ 120.00

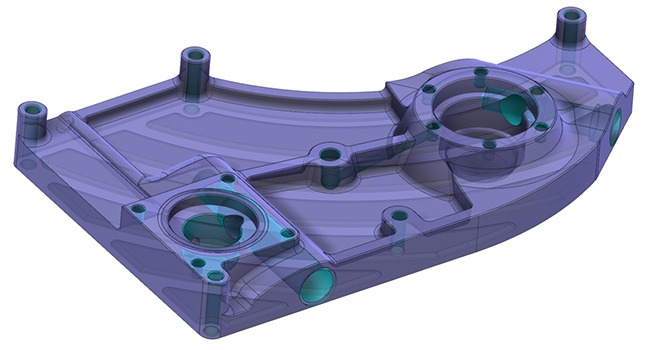

Mastercam 2024 is a professional and powerful CAD/CAM design assistance software. The official version of Mastercam 2024 supports 2D drawing, 3D Solid modeling, surface design, voxel assembly, NC programming and other functions, which can improve the design efficiency of users. Mastercam 2024 software has powerful grid creation and editing functions, providing users with greater flexibility.

Description

6 New CAD Features to Explore in Mastercam 2024

Mastercam Design is a computer-aided design solution that simplifies the creation of even the most complex parts with a robust suite of CAD tools. Mastercam 2024 is here and elevates your machining experience with powerful toolpaths, flexible tool motion, and our most intuitive interface yet. Here are some top CAD features—and how they can help your shop.

1. Note Workflow Improvement

Mastercam 2024 improves efficiency with a simple change to the Note workflow. In previous versions, you would have to interact with the panel every time you wanted to add or delete a leader line to a note. Now, you can simply indicate the new position in the graphics window to add additional leader lines.

2. Enhancing MCO Conversion Options for Component Models

Typically, the solid models in .machine files and component libraries are converted to Mastercam’s proprietary MCO format before being released. This is an encrypted mesh format that prevents the models from being edited, preserving the intellectual property of the person/company who supplied the models. In Mastercam 2024, this functionality has been enhanced so that models can be converted to either regular Mastercam mesh entities or MCO entities.

3. Controlling the Orientation of Disassembled Solids or Mesh Bodies

Mastercam orients disassembled solid and mesh bodies on their largest, flat face. The only way to control the orientation of the disassembled solids was to enable Face Selection and disable Body Selection, making it possible to place specific faces on the layout plane. But, you can’t use this method if the opposing faces of the selected bodies were equal. To provide more control in these situations, Mastercam 2024 lets you use the color of a face to orient the disassembled bodies.

4. Solid Hole Enhancements

There have been many enhancements to Mastercam’s hole-making functions that will be helpful in drilling and Process Hole operations.

Smooth Edges of Solid Holes: Mastercam 2024 now offers an easy way to break the hole edges in solid parts. Hole operations in this release now include options for edge treatment from within the function panel. Before Mastercam 2024, you could only create a chamfer at the top edge of a hole. With 2024, a new Top Edge Treatment allows you to create either chamfers or fillets on your hole edge.

Create New Operations from a Single Hole Operation: Mastercam 2024 makes incorporating design changes to existing holes in your solid easier. New options in the Solids manager and the Hole panel allow you to create, move, or copy hole operations from hole operation groups.

Changing Direction of Existing Through Holes: In Mastercam 2024, a new Reverse Hole button has been added, allowing you to flip the direction of selected through-holes. It moves the hole’s associative point to the opposite end of the hole and reverses the vector.

5. Smoothly Attach Spline Endpoints

Mastercam 2024 adds more improvements to wireframe modification. A new option in the Edit Spline function creates a smooth transition from the endpoint of the selected spline to an endpoint on another entity. When you select the Align end tangents option, Mastercam matches the tangency of the repositioned spline endpoint to that of the destination endpoint. The blended geometry results in a continuous curvature of the geometry and a better foundation for surface creation.

6. Trim, Break, and Extend Wireframe Entities

With the new Dynamic Trim functions, Mastercam 2024 introduces multiple trimming functions into a single panel. Dynamic Trim combines Trim to Entities, Divide, Trim to Point, and Modify Length into one panel, allowing you to easily apply any of these functions to wireframe geometry without having to open a separate panel.

Mill-Turn Additions and Enhancements. Users can now use turret-mounted angled milling heads in Mill-Turn operations, allowing you to create toolpaths on angled planes using turret-mounted tools which results in enhanced productivity and ease of use for both milling and turning operations. B-Axis Contour Turning also sees three major enhancements—the ability to manually edit tool axis vectors, manually edit usable insert area, and adjust stock function— which allows for more in-process control and understanding of the motion of the B-axis head from within the toolpath interface.

Process Hole and Holemaking Enhancements. The Process Hole toolpath applies previously defined processes to a part’s solid hole features, which consists of one or more holemaking operations’ built-in functions library. The ability to import applicable processes into the working part file saves time and money while maintaining consistency with your processes. A displayed graphical elements button has been added to the holemaking and multiaxis toolpath dialog boxes, permitting you to show or hide graphical elements depending on the toolpath type. This allows for more customized control on a hole-by-hole basis or across the entire holemaking toolpath.

Milling Enhancements. The Dynamic Mill, Face, and Dynamic OptiRough toolpaths now include a new Maximize Engagement option, producing more nominal chips, minimizing the number of small chips, and helping prevent problematic stand-alone material slivers. Waterline toolpaths are now aware of undercut stock conditions resulting in improvement to the toolpath motion and less air cutting.

General System Features and Updates. Mastercam’s traditional on-screen gnomon has been augmented with the new Gview cube which is a more graphical way to show plane orientation and its interactive features allow users to control the cube and on-screen representation of the part. Machine Group Setup Stock has three new easier, more intuitive selection methods including Add from two corner, Add rectangular stock, and Add cylindrical stock. The Save/Load Toolpath Defaults List enhancement allows a user to specify individual files and operations to load from/save to. The ability to quickly switch between different default sets for different toolpath goals or transfer operational data from file to file delivers time savings, an enhanced user experience, and improved functionality.

CNC Software Solutions

CAD/CAM software is used to translate computer-aided design (CAD) to manufacturing workpieces with computer-aided manufacturing (CAM) on your CNC machine.

Mastercam offers CAD/CAM software tools for a variety of CNC programming needs, from basic to complex. Due to our innovative, flexible solutions and top notch network of support, our software is a complete solution from the start of design through to manufacturing. Choose Mastercam to streamline your production process from job setup to job completion.

CNC Software Products

Our CAD CAM software products take parts from design through to the production line. Program your manufactured parts with leading-edge features for precision and efficiency. Creating code to drive your CNC equipment is what Mastercam does best.

CNC Software Specialty Add-Ons

Build your comprehensive CAD/CAM solution with Mastercam. Enhance your productivity with a variety of specialized Add-Ons for your specific machining needs.

CAD/CAM 3rd Party Add-Ons

Mastercam partners with top CAD/CAM software integration experts in the manufacturing industry, so you can choose from complementary software tools, hardware, and more to boost your bottom line with a complete manufacturing solution.

Frequently Asked Questions

What is CAD/CAM Software?

CAD/CAM software controls CNC machines like mills, routers, lathes, and wire EDMs. CAD stands for computer-aided design, and CAM stands for computer-aided manufacturing. CNC stands for computer numerical control. Mastercam is a software that provides both CAD and CAM functionality to drive CNC machines efficiently for optimized productivity.

How does CAD/CAM software improve manufacturing quality?

CAD/CAM software eliminates errors that can occur when manually programming a CNC machine. It also allows adaptability and offers methods of precision machining that are impossible through manual programming.

What is CAD/CAM software used for?

CAD software is used for designing parts, fixtures, and assemblies. It can be used to create parts from scratch, to modify existing designs, or to prepare parts for machining. CAM software is used to program toolpaths and to generate the G-code that controls CNC machines like mills, routers, lathes, and wire EDMs. CAD/CAM software, like Mastercam, is used to take parts from design through production within a single, user friendly interface.

What are the advantages of using CAD/CAM software?

CAD/CAM software offers advantages that are not attainable with manual programming. These include quick generation of G-code for CNC machines, the ability to program extremely complex parts, plus digital review and evaluation of a project before physical machining starts.

Why is CAD/CAM software used in manufacturing?

CAD/CAM software is used in manufacturing for increased automation. This automation saves time, reduces errors, and improves both precision and productivity in the manufacturing process. Mastercam is a leading CAD/CAM software provider in the manufacturing field.

What is the difference between CAD and CAM software?

CAD and CAM software can be used in tandem for manufacturing, but they are distinct types of software. CAD is software for computer-aided design, while CAM is software for computer-aided manufacturing. CAD is used to design or modify an object, while CAM is used to control a machine used to produce an object.