Moldex3D 2025 R1

$ 160.00

Moldex3D 2025 R1 is the leading CAE software for plastic injection molding simulation. Improve product quality, reduce costs, and optimize mold design with powerful 3D analysis tools…

Description

Moldex3D 2025 – The Most Advanced Injection Molding Simulation Software for Engineers & Product Designers

Moldex3D 2025 is the latest and most powerful version of the industry-leading CAE simulation software for plastic injection molding. Trusted globally by engineers, mold designers, and manufacturing professionals, Moldex3D delivers accurate, AI-driven simulations that reduce development cycles, cut production costs, and eliminate defects early in the design process. With the 2025 release, Moldex3D sets a new standard in smart automation, intelligent optimization, and high-performance computing.

Whether you’re working in automotive, electronics, medical devices, or industrial packaging, Moldex3D 2025 equips you with next-generation tools for injection molding simulation, cooling analysis, warpage prediction, and fiber orientation modeling — all in a seamless 3D environment.

🌟 New Features & Enhancements in Moldex3D 2025

✅ AI-Powered Optimization & Smart Assistants

Moldex3D 2025 introduces AI-based design assistants that dramatically reduce manual trial-and-error:

-

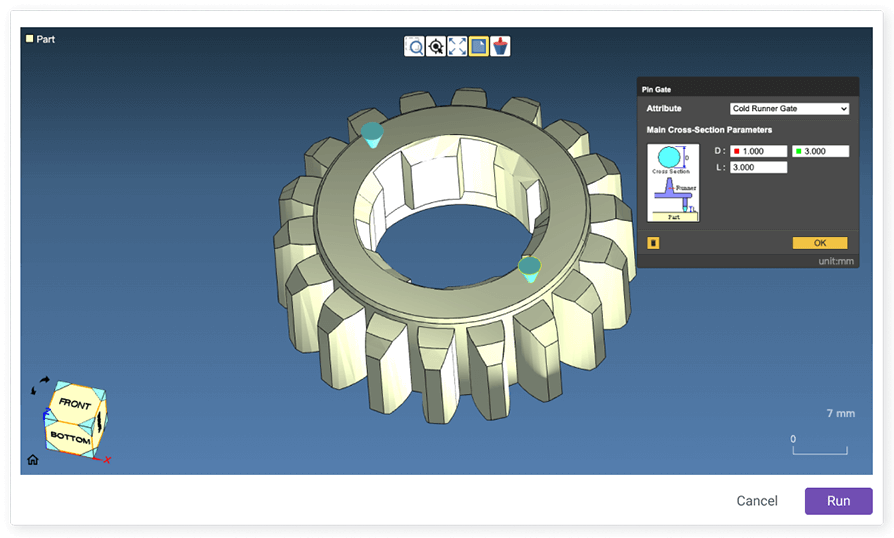

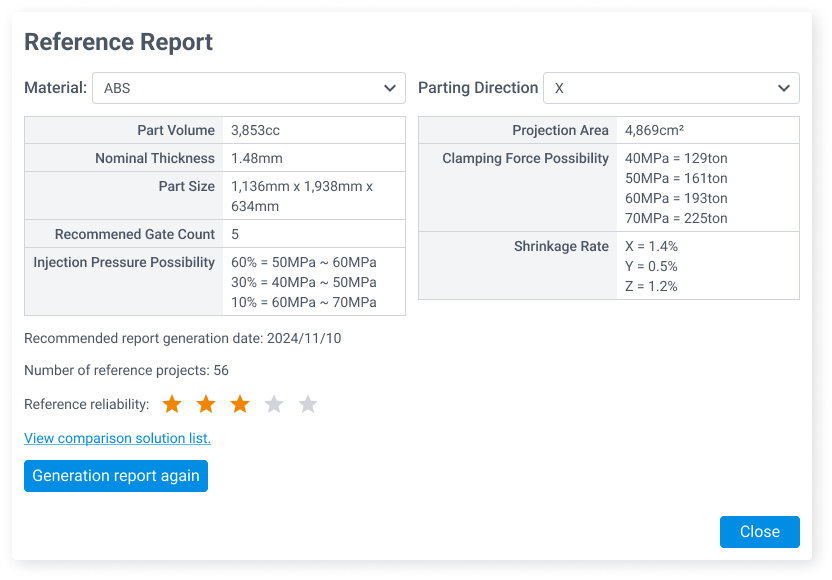

Gate Design Discovery & Mold Design Discovery: Automatically identifies the best gate locations and mold layouts based on prior simulations and geometry analysis.

-

Moldibot: A built-in digital assistant that offers design insights, simulation setup suggestions, and automated result analysis.

-

Optimization Wizard: Supports multi-objective design of experiments (DOE) and process parameter tuning using AI to achieve faster, better product outcomes.

✅ Enhanced Thermal & Crystallinity Simulation

-

Thermal Pin Simulation: More accurate heat transfer analysis for thermal control in molds.

-

Crystallinity Prediction: Analyze material behavior under annealing conditions to forecast warpage and shrinkage in semi-crystalline polymers with greater precision.

✅ IC Packaging and Semiconductor Analysis

-

Wire Debonding Analysis: Evaluate and prevent wire lift-off during encapsulation for IC packaging, ensuring better reliability in electronics manufacturing.

✅ Smarter Preprocessing Automation

-

Component Matching Automation: Simplifies multi-component model setup.

-

Cooling Channel Repair Tools: Automatically detects and fixes curve issues such as overlaps and intersections in cooling system designs.

-

Contact Surface Validation: Detects incomplete or misaligned part contacts before meshing begins, saving time and reducing human error.

✅ Workflow Automation and API Integration

-

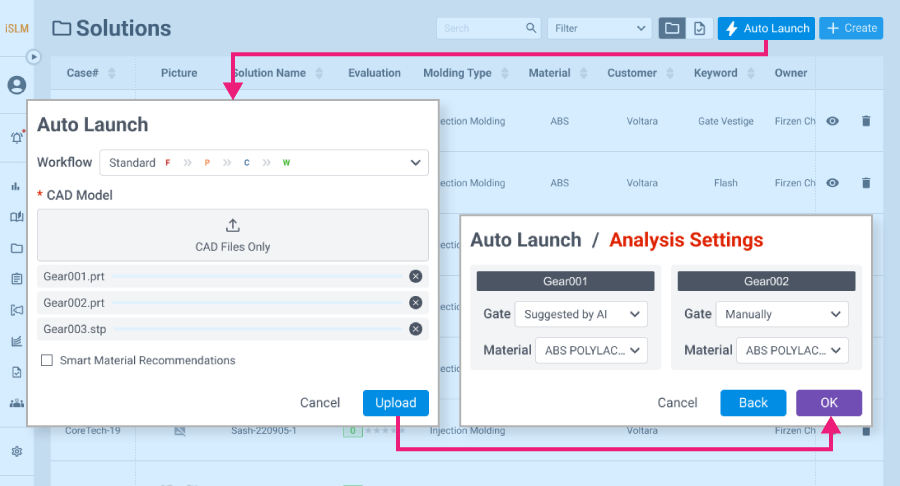

iSLM Auto Launch: Automatically launches simulations from uploaded CAD files, initiates mesh generation, and sets up analysis projects with minimal user input.

-

Molding Window Advisor: Generates optimal processing windows automatically based on material and geometry.

-

Open API Support: Enables integration into cloud-based systems or enterprise software tools, including compatibility with Google Cloud, Linux clusters, and on-premises HPC.

✅ Advanced Visualization and Reporting

-

Elliptical Fiber Orientation View: Gain deeper insights into flow-induced fiber orientations using improved visualization.

-

3D Flake Rendering for CFRPs: Accurately simulate composite flake orientation in fiber-reinforced plastics.

-

Real-time DOE Prediction Charts: Interactive graphs help users instantly visualize parameter effects.

-

Verification Templates: Customizable templates let users define key evaluation metrics and generate reports that comply with internal or industry standards.

✅ Massive Performance & File Efficiency Improvements

-

File Size Compression: Project files reduced by up to 66%, resulting in faster loading, saving, and easier storage management.

-

Solver Speed Enhancements: Significant speed-ups in fill, pack, and cooling simulations with more stable convergence.

🛠 System Requirements for Moldex3D 2025

To maximize Moldex3D’s capabilities, ensure your system meets the following specifications:

🖥 Recommended Hardware:

-

CPU: Intel i7 or Xeon (8+ cores) / AMD Ryzen 9 or EPYC for high-speed simulation

-

RAM: 32 GB minimum (64+ GB recommended for large models)

-

GPU: NVIDIA graphics card (RTX or Quadro series) for enhanced 3D rendering

-

Storage: SSD (512 GB+) recommended for optimal performance

🧰 Supported Operating Systems:

-

Windows: Windows 10 (22H2 or later), Windows 11

-

Linux (Solver Only): Rocky Linux 8.8+, CentOS 7.9

-

Cloud Compatibility: Supports Google Cloud, AWS, and hybrid HPC setups

📦 CAD Compatibility:

-

Supports import from all major CAD systems: SOLIDWORKS, NX, CATIA, PTC Creo, Autodesk Inventor, and STEP/IGES/STL files.

-

Integrates with CADdoctor for model healing and mesh optimization.

🐞 Bug Fixes & Stability Improvements in 2025 R1

The latest patch, Moldex3D 2025 R1, includes important fixes that enhance performance and reliability:

-

Resolved CAD import issues from NX and CATIA, especially involving assemblies with complex mating.

-

Fixed symmetry mesh issues causing preprocessing crashes.

-

Improved automatic contact detection for multi-part assemblies.

-

Corrected thermal pin simulation behavior in over-molded parts.

-

Stabilized Linux-based solver operations for distributed computing environments.

-

Fixed API call inconsistencies affecting automated workflows in some enterprise environments.

These fixes ensure a smoother user experience and more dependable simulation results across a wide range of workflows and industries.

💼 Industries That Benefit from Moldex3D 2025

-

Automotive: Bumper covers, dashboards, lighting lenses, intake manifolds

-

Consumer Electronics: Housings, connectors, mobile device frames

-

Medical Devices: Syringes, catheter hubs, diagnostic components

-

Aerospace & Defense: Lightweight composite parts, brackets

-

Packaging: Caps, closures, thin-wall containers

-

IC Packaging: Encapsulation, wire bonding, thermal performance

🚀 Why Choose Moldex3D 2025?

Moldex3D 2025 isn’t just a simulation tool—it’s a complete smart manufacturing solution. With intelligent automation, physics-based accuracy, and AI-powered design tools, it enables teams to move faster, design smarter, and manufacture better. It’s the most comprehensive way to simulate, validate, and optimize your plastic injection molding process—before cutting steel.

⭐️⭐️⭐️⭐️⭐️5/5

“Moldex3D 2025 takes injection molding simulation to the next level.”

As a CAE engineer, I’ve seen major improvements in simulation accuracy, speed, and usability. The new AI tools like Gate Design Discovery and the Optimization Wizard save hours of setup time, while features like thermal pin and crystallinity analysis help us reduce warpage early in the design phase. File sizes are smaller, results are clearer, and our process is more efficient. Moldex3D 2025 is a must-have for any team focused on high-quality mold design and plastic part optimization.