MAXSURF 22.0 cracked license software

$ 150.00

MAXSURF Update Notes –

Release 22.00 (CONNECT Edition) December 2018

- CONNECT Licensing is Bentley’s new process for product activation, enhancing the users’ digital workflows and improving licensing capabilities:

- License alert notifications when you are approaching a custom usage threshold

- Replacing site activation keys with user validation, enhancing security around your Bentley licenses and subscriptions

Description

The MAXSURF suites of software provide a comprehensive range of capabilities for the design of all types of marine vessels.

The technology has been used for more than 30 years on thousands of vessels worldwide, providing naval architects with a complete range of software tools for all phases of the design process.

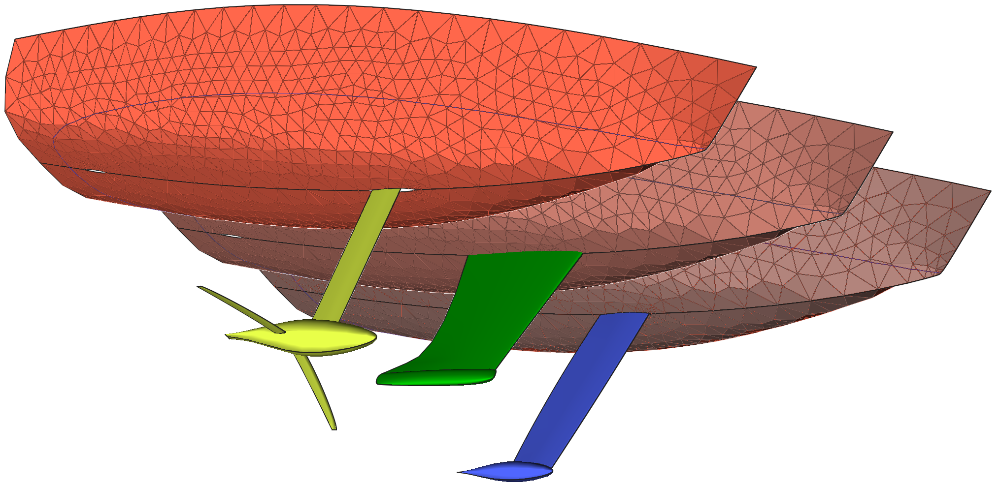

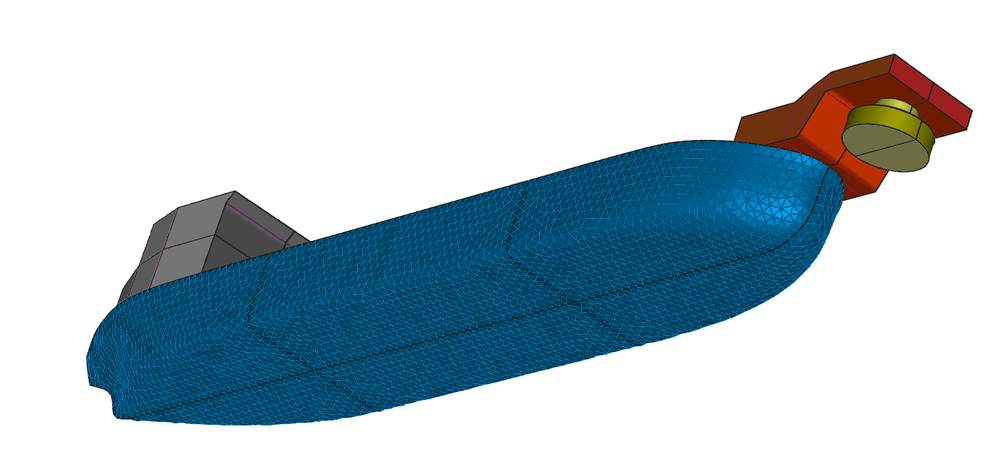

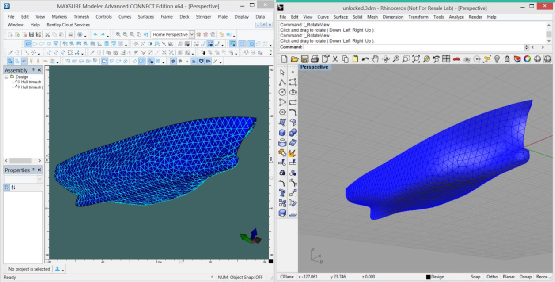

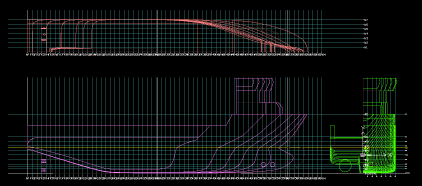

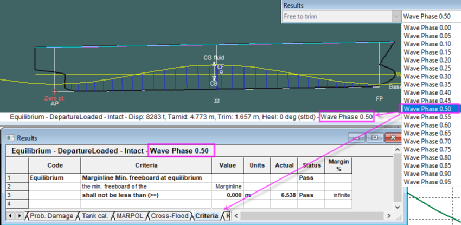

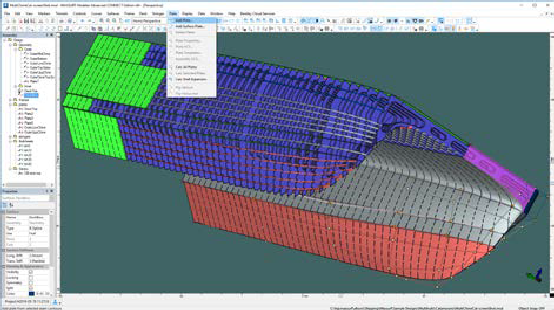

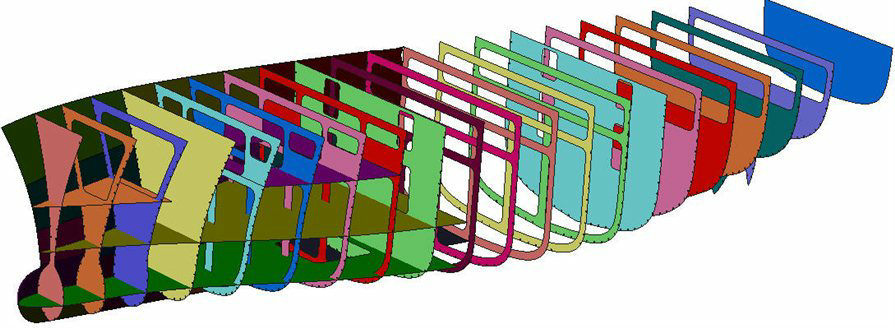

MAXSURF includes tools for hull modelling, stability, motions and resistance prediction, structural modelling, structural analysis, and export to vessel detailing.

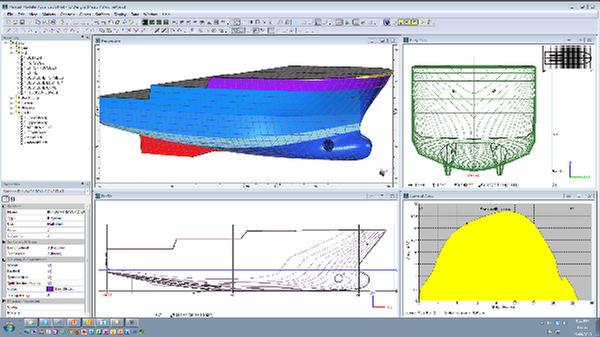

MAXSURF software applications operate from a single parametric 3D model that facilitates smooth communication and coordination between different team members and design activities.

All MAXSURF modules share a consistent Microsoft Windows graphical interface which reduces training time, greatly increases ease of use, and helps designers and builders visualise complex configurations.

MAXSURF is based on industry standards like NURB surface modelling, DXF and IGES data exchange and smooth data transfer with Microstation, Rhino, AutoCAD, ShipConstructor, SolidWorks and Microsoft Office programs..

KEY ADVANTAGES

The MAXSURF suites offer some key advantages over alternative software. Some of these include:

SINGLE 3D HULL MODEL

All programs in the MAXSURF suite work from a single design file, streamlining the design process by removing the need to create geometry files in different formats for downstream analysis programs.

TRUE WINDOWS INTERFACE

All modules in the MAXSURF range were designed from the start to operate with a Graphical User Interface, and the result is a consistent design that is easy to learn and use across all design & analysis modules.

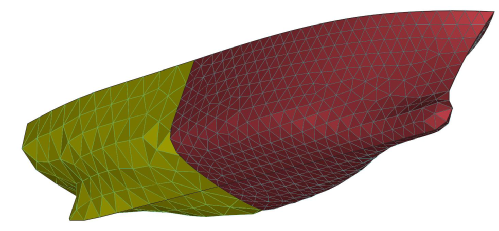

HIGH QUALITY SURFACING

MAXSURF is optimised to help naval architects create high quality hull surfaces which are fair and can be used for all other analysis and CAD/CAM functions.

COMPREHENSIVE ANALYSIS

The MAXSURF suite includes intact and damage stability, longitudinal strength, structural analysis and design, resistance prediction, wake calculation, motions prediction, and a sailing VPP.

DYNAMIC TRIMMING

Surface trimming in MAXSURF is a simple point and click process. Most importantly, MAXSURF’S trimming is fully dynamic, allowing you to modify trimmed surfaces and have the trimmed portions automatically update.

INTEROP WITH RHINO & OTHER SYSTEMS

MAXSURF reads and write Rhino files and also features interchange with Microstation, ShipConstructor, AutoCAD, SolidWorks, ShipFlow and other CAD/CAE/CAM systems.

MAXSURF and Multiframe have been developed by Formsys since 1984.

Formsys was previously named Graphic Magic then Formation Design Systems.

Over 3000 of the MAXSURF products have been distributed in over 30 countries worldwide by authorised distributors including Island Computer Systems Ltd in the UK and Europe.

Formsys was purchased by Bentley Systems in 2011.

Bentley provide a large portfolio of infrastructure products and are developing an ‘offshore’ arm which incorporates SACS, MAXSURF and MOSES.

Island Computer Systems Ltd is a Bentley Gold Channel Partner authorised to provide MAXSURF, Multiframe, MicroStation, PowerDraft in particular and all of the Bentley portfolio in general.

Island Computer Systems Ltd are associate members of RINA – l Institute of Naval Architects. Formsys is a corporate member of RINA.

l Institute of Naval Architects. Formsys is a corporate member of RINA.

The purpose of this website at maxsurf.net is to provide a helpful source of information for those interested in MAXSURF particularly in and near Europe.

FormSys excels as a pioneering software development company specialising in 3D modelling, analysis and design software. Specialist areas of application include naval architecture and shipbuilding, offshore engineering and structural engineering. Their 30 years experience in CAD/CAE/CAM software makes them one of the more experienced companies in the industry.

Formsys Naval Architecture & Shipbuilding

Since 1984, the MAXSURF suite of naval architecture and ship construction software formed the cornerstone of their offerings to the naval architecture profession. Over 1000 designers and companies use MAXSURF to design all types of vessels ranging from pleasure boats through to workboats and large ships. MAXSURF users include major Japanese shipbuilders, Damen Shipyards, US Navy, US Coast Guard, Bath Iron Works, Austal Ships, BAE Systems, Incat Designs, Americas Cup syndicates and leading European luxury yacht designers.

Behind the software systems is their team of naval architects and engineers. Most of their technical staff members come from a naval architecture, shipbuilding or engineering background. This helps them provide advice which is both practical and technically deep.

Structural Engineering

The Company’s Multiframe software range is used by over 2000 companies world-

Multiframe is particularly widely used in Japan and Australia. Their outlook has always been international and they provide localised versions in the local language and supporting local design codes.

Design Philosophy

All of FormSys’ products are characterized by their three main design criteria –

Intuitive Graphical Interface

All products use a consistent graphical interface which allows direct graphical manipulation of the 3D model as well as numerical specification of design parameters. A multi-

Integrated database with parametric design capabilities

Each product creates a full 3D database which is used directly by all design and analysis modules. This eliminates the need for file format exchanges between disciplines and departments within a design and construction company. The parametric approach adopted allows changes to “flow through”, allowing designers using the software to explore more design alternatives and achieve improved optimization.

Support for industry standards

All FormSys products run on the industry standard Microsoft Windows platform. User interface design conforms with Microsoft recommendations and allows users familiar with any other Windows applications, to rapidly learn and master the programs.

Data exchange is provided for the common CAD formats and also extends to copy and paste interchange both to and from Microsoft Office applications as well as full Automation support allowing our applications to be scripted from Excel, Word and MathCAD.

Software Technology

All FormSys’ CAD products are based on leading edge software technology including C++ object oriented development, a modularized approach to system design and use, 3D rendering and animation standards, and advanced algorithms like trimmed NURB surfaces and non-

Customer Support

FormSys has an excellent reputation for providing timely and practical customer support with a team of highly skilled technical staff to help solve customer problems. A number of our staff have Masters or PhD degrees in engineering or naval architecture, as well as practical experience in design and construction.