FLOW-3D 2022R2 cracked license

$ 150.00

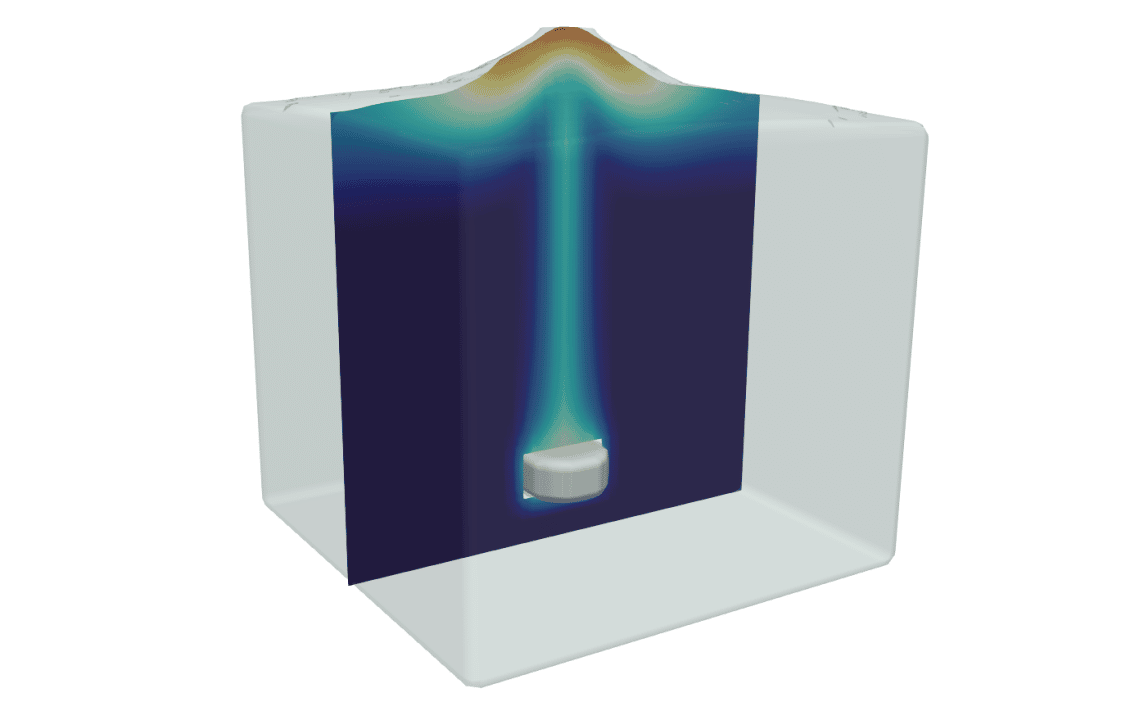

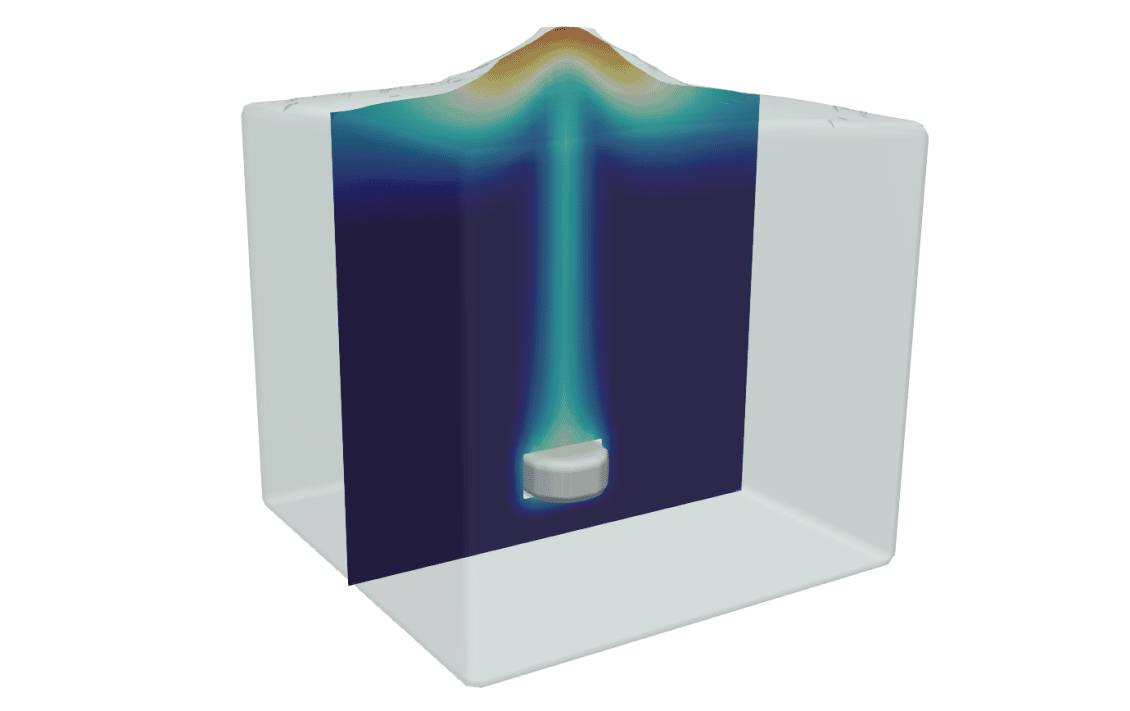

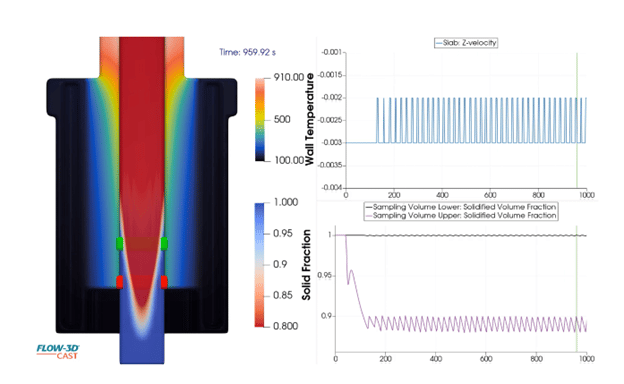

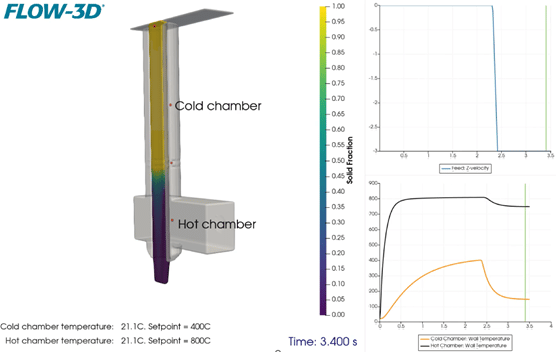

Optimize product designs and reduce time to market with FLOW-3D, a highly-accurate CFD software that specializes in solving transient, free-surface problems. FLOW-3D‘s complete multiphysics suite includes our state-of-the-art postprocessor, FLOW-3D POST.

FLOW-3D provides a complete and versatile CFD simulation platform for engineers investigating the dynamic behavior of liquids and gas in a wide range of industrial applications and physical processes. FLOW-3D focuses on free surface and multi-phase applications, serving a broad range of industries including microfluidics, bio-medical devices, water civil infrastructure, aerospace, consumer products, additive manufacturing, inkjet printing, laser welding, automotive, offshore, energy and automotive.

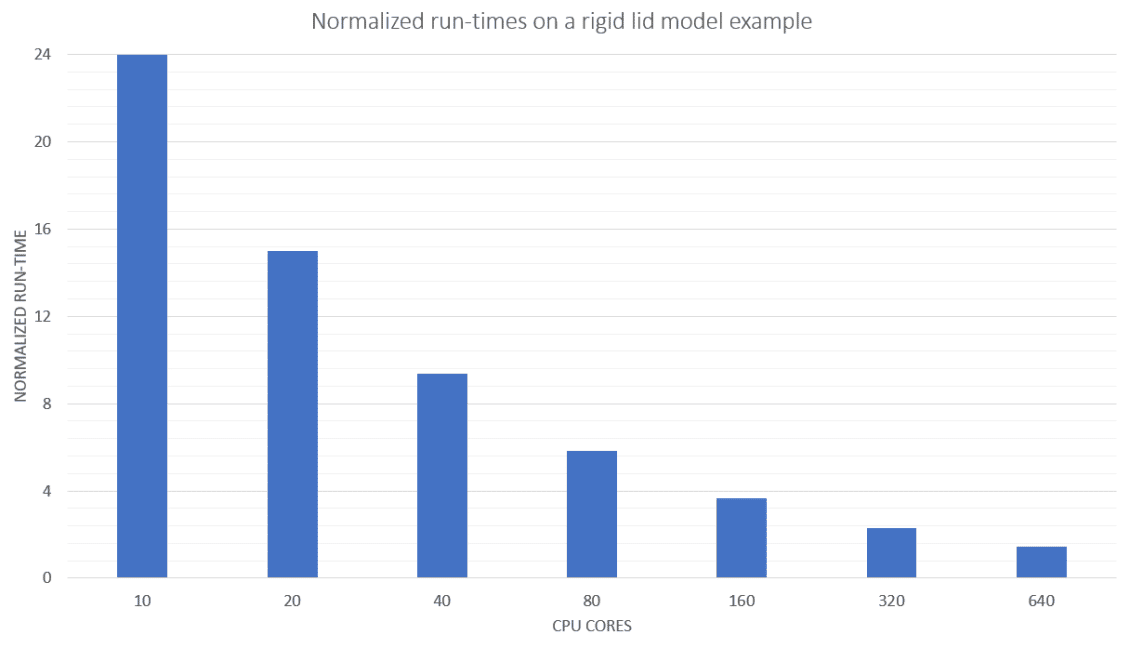

A uniquely powerful, multiphysics tool, FLOW-3D provides the functionality, ease-of-use and power that helps engineers advance their modeling objectives. Built for the highest level of performance, FLOW-3D seamlessly scales from standard workstations to hundreds of CPU cores on high performance computing solutions.

Description

What’s New in FLOW-3D 2022R2

With the release of the FLOW-3D 2022R2 product family, Flow Science has unified the workstation and HPC versions of FLOW-3D to deliver a single solver engine capable of taking advantage of any type of hardware architecture, from single node CPU configurations to multi-node parallel high performance computing executions. Additional developments include a new log conformation tensor method for visco-elastic flows, continued solver speed performance improvements, advanced cooling channel and phantom component controls, and improved entrained air functionalities.

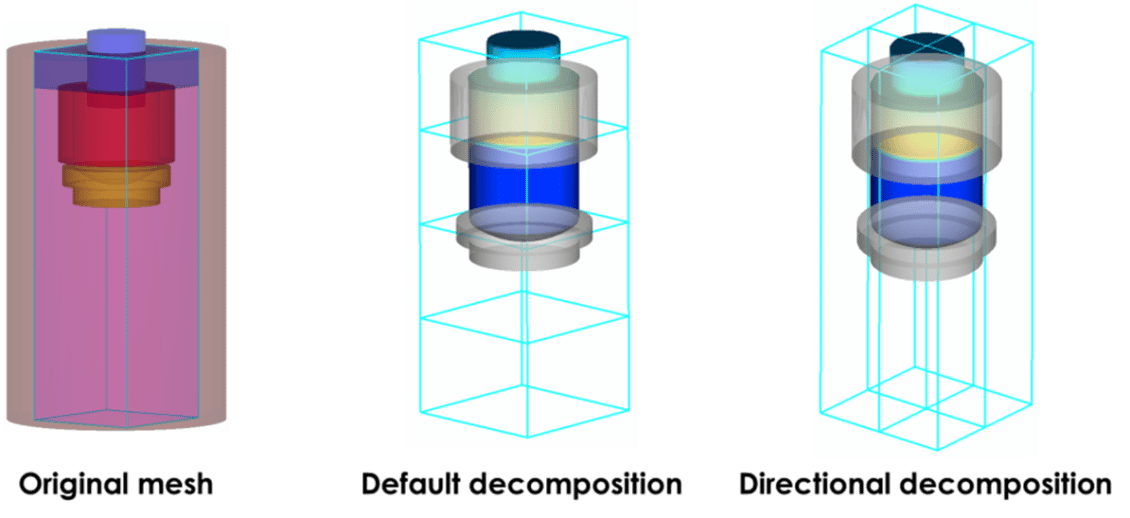

Unified solver

We migrated our FLOW-3D products to a single, unified solver to run seamlessly on local workstations or on high performance computing hardware environments.

Many users run their models on laptops or local workstations, but in addition run larger models on high performance computing clusters. With the 2022R2 release, the unified solver allows users to exploit the same benefits of OpenMP/MPI hybrid parallelization from HPC solutions to run on workstations and laptops.

Solver performance improvements

Multi socket workstations

Multi socket workstations are now very common and capable of running large simulations. With the new unified solver, users using this type of hardware will generally see performance gains from being able to run models taking advantage of OpenMP/MPI hybrid parallelization that used to be only available on HPC cluster configurations.

Low level routines improved vectorization and memory access

Performance gains on the order of 10% to 20% have been observed for most test cases, with some cases yielding run-time benefits in excess of 20%.

Refined volumetric convective stability limit

Time step stability limit is a major driver in model runtime, with 2022R2, a new time step stability limit, 3D convective stability limit, is available in the numerics widget. For models that are running and convection limited (cx, cy, or cz limits) the new option has shown typical speed-ups on the order of 30%.

Pressure solver pre-conditioner

In some cases, for challenging flow configurations, run times can be drawn out due to excessive pressure solver iterations. For those difficult cases, with 2022R2, when a model iterates too heavily, FLOW-3D automatically activates a new pre-conditioner to help with pressure convergence. Tests have improvements in runtime anywhere from 1.9 to 335x faster!

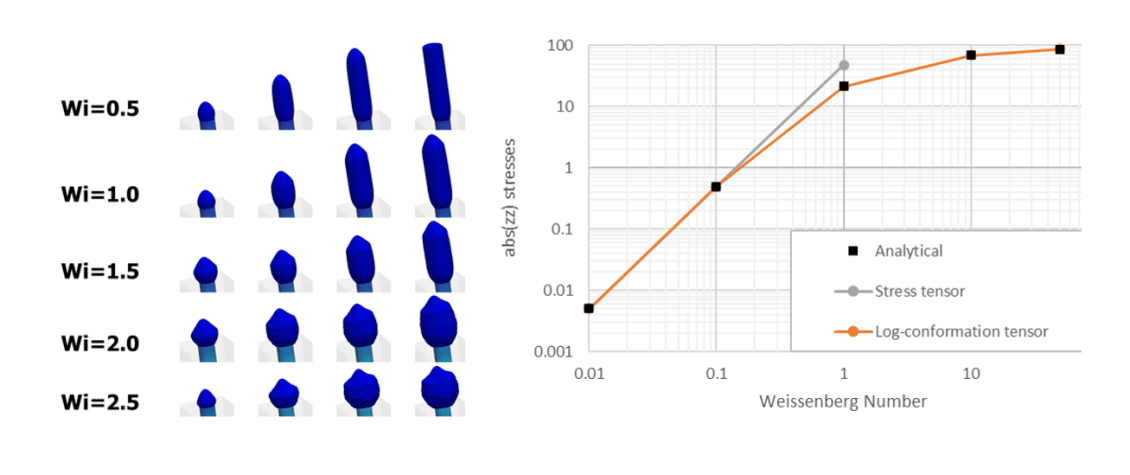

Log conformation tensor method for visco-elastic fluids

A new solver option for visco-elastic fluids is available to our users, and is particularly effective for high Weissenberg numbers.

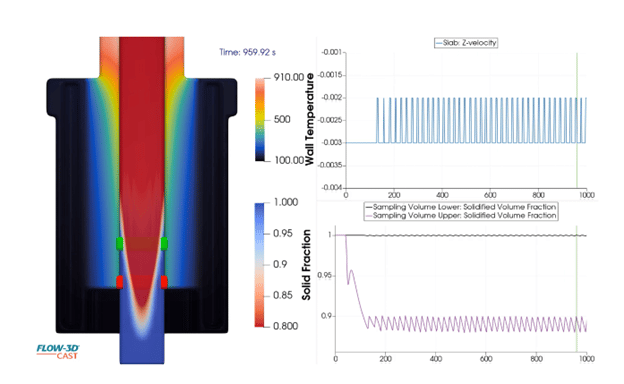

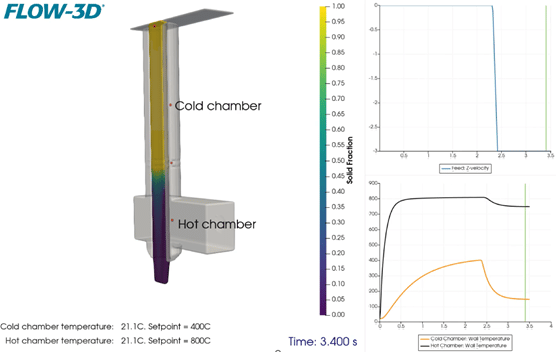

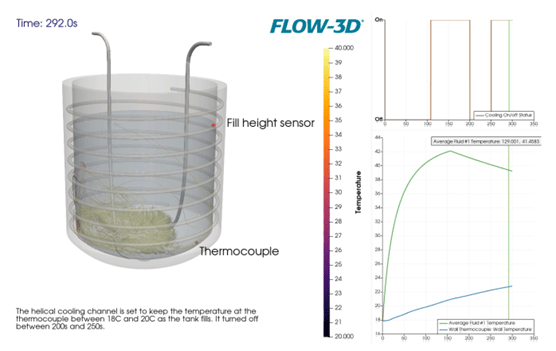

Active simulation control extensions

Active simulation control functionalities have been extended to include phantom objects, commonly used for continuous casting and additive manufacturing applications, as well as for cooling channels, used in casting and in many other thermal management applications.

Previous

Next

Improved entrained air functionalities

For diffusers and similar industrial bubble flow applications, mass sources can now be used to introduce air into the water column. In addition, default values for the turbulent diffusion of entrained air and dissolved oxygen have been updated, and model accuracy for very low air concentrations has been improved.

Related products

-

Sale!

Wilcom Embroidery Studio E3 Designing cracked with dongle emulator

$ 3,000.00Original price was: $ 3,000.00.$ 110.00Current price is: $ 110.00. Add to cart Quick View -

Tebis V4.0 R4 full cracked version

$ 160.00 Add to cart Quick View -

ICAM CAM-POST NC Post-Processing Solution V18 cracked

$ 185.00 Add to cart Quick View -

Sale!

HYDROSTATICS SUITE cracked version

$ 1,725.00Original price was: $ 1,725.00.$ 200.00Current price is: $ 200.00. Add to cart Quick View -

GPRSIM v3.0 cracked version

$ 130.00 Add to cart Quick View -

ETAP 14.1 cracked version download

$ 140.00 Add to cart Quick View -

Sale!

Intergraph Smart 3D 2016 cracked version

$ 180.00Original price was: $ 180.00.$ 135.00Current price is: $ 135.00. Add to cart Quick View -

Sale!

Intergraph TANK NEW cracked version

$ 180.00Original price was: $ 180.00.$ 150.00Current price is: $ 150.00. Add to cart Quick View -

Sale!

CamLink cracked version

$ 200.00Original price was: $ 200.00.$ 155.00Current price is: $ 155.00. Add to cart Quick View -

Sale!

ONBOARD PROGRAMS

$ 5,800.00Original price was: $ 5,800.00.$ 180.00Current price is: $ 180.00. Add to cart Quick View