CGTech Vericut 9.5.3 full cracked version released

$ 160.00

VERICUT 9.5.3 by CGTech – advanced CNC simulation and optimization software. Prevent collisions, reduce machine downtime, and improve part quality with powerful NC verification tools…

Description

VERICUT 9.5.3 CNC Simulation Software by CGTech – Precision NC Code Verification, Machining Optimization & Real-Time Machine Connectivity

VERICUT 9.5.3, developed by CGTech, is the latest and most advanced version of the world-renowned CNC machine simulation, verification, and optimization software. Built for manufacturing professionals, CAM programmers, and production engineers, VERICUT ensures that your NC programs are safe, accurate, and optimized before reaching the shop floor—saving you time, money, and materials.

VERICUT has been the industry standard for decades in detecting programming errors, avoiding collisions, and improving machining efficiency. The 9.5.3 release takes this even further with a range of powerful new features, improved machine connectivity, enhanced user interaction, and expanded support for modern manufacturing workflows.

🚀 Key Highlights and New Features in VERICUT 9.5.3 :

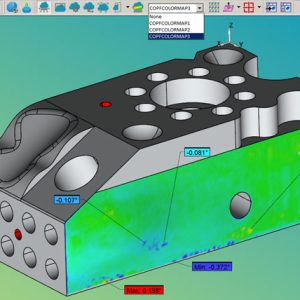

✅ Tool Usage & Wear Visualization

A groundbreaking Heat Map tool in the Tool Summary window provides visual representation of tool wear, load distribution, and cutting performance. Users can set custom wear thresholds based on cutting time, material volume, or distance traveled. When limits are exceeded, VERICUT notifies users, helping them stay ahead of tool failures and reducing unscheduled downtime.

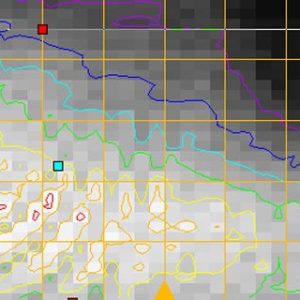

✅ CNC Machine Connectivity and Live Data Integration

Connect VERICUT directly to supported CNC machines—including those from OKUMA, Siemens, and Heidenhain. Access real-time machining data before, during, and after operations. Use the new Postcheck tool to replay actual machine data inside a VERICUT simulation and analyze performance, override conditions, feed rate reductions, or stops.

✅ Enhanced Coordinate System and Model Management

Easily translate and rotate coordinate systems, models, and assemblies using a powerful new interactive interface. Visual cues assist users in previewing changes, making it easier to align models correctly and reduce programming setup errors—especially useful for 5-axis and multi-setup projects.

✅ Improved CAM System Interfaces

VERICUT 9.5.3 offers seamless integration with leading CAM platforms like Mastercam, NX, CATIA, and HyperMill. The Mastercam interface has been significantly enhanced to automatically define fixtures, stock, and design geometry directly from Mastercam’s setup, reducing manual steps and potential errors. The interface now supports runtime changes in language and configuration—no restart required.

✅ Smarter Learn Mode Optimization

VERICUT’s enhanced Learn Mode intelligently distinguishes between tool usage across various operations—such as roughing, semi-finishing, and finishing. This allows the software to generate optimized cutting strategies tailored to each phase, increasing overall tool efficiency and surface finish quality.

✅ Interactive Simulation Timeline

The upgraded Tool Use window now includes a clickable timeline that maps tool engagement and critical events. Click on any marker—such as an error, collision, or warning—and VERICUT instantly jumps to the relevant simulation step and NC code, streamlining diagnostics and reducing troubleshooting time.

✅ Automated Simulation Notifications

Stay informed with email or Microsoft Teams alerts after simulation runs. Receive summaries, error logs, and key insights automatically. VERICUT can also notify users in real-time during simulation if specific events, such as tool changes or collisions, occur.

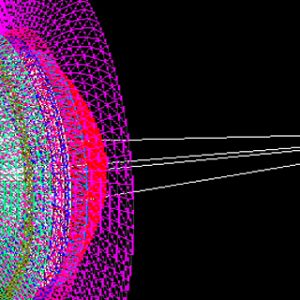

✅ New EDM & Fanuc Simulation Capabilities

Support for EDM Die Sinking simulations with a new “Electrode” tool type is now available, including full 5-axis electrode movements. Plus, integration of Fanuc CNC digital twin simulators enables users to validate their programs in a realistic virtual environment—before cutting a single part.

💬 Real Developer Review :

“As a CNC programmer working with high-value aerospace parts, VERICUT 9.5.3 has become an essential part of our workflow. The new heat map and tool wear features give us a clear picture of tool usage, helping us avoid downtime and plan more efficiently. The direct connection to our Heidenhain machines allows for real-time validation, which has saved us from multiple potential collisions. The simulation accuracy and postcheck capabilities are unmatched. VERICUT continues to be the gold standard for NC code verification and optimization.”

— Daniel K., CNC Programmer – Aerospace Manufacturing Sector

🖥️ System Requirements for VERICUT 9.5.3 :

To ensure optimal performance, your workstation should meet the following specifications:

-

Operating System: Windows 10 or Windows 11 (64-bit)

-

Processor: Intel Core i7/i9 or AMD Ryzen 7/9 (multi-core)

-

Memory: Minimum 16 GB RAM (32 GB or more recommended for complex parts)

-

Graphics Card: NVIDIA Quadro or GeForce RTX series recommended (OpenGL support required)

-

Storage: 10+ GB free SSD space for installation and simulation data

-

Display: Full HD resolution (1920×1080 minimum); 4K recommended

-

Network: Internet connection required for license management and cloud notifications (optional but recommended)

🛠️ Bug Fixes and Performance Enhancements :

VERICUT 9.5.3 delivers improved performance, better reliability, and dozens of bug fixes, including:

-

Fixes for transformation errors in 4- and 5-axis multi-setup simulations

-

Better memory optimization and faster loading for complex model assemblies

-

Resolved issues with timeline marker rendering and click-to-review navigation

-

Enhanced CAM import accuracy—especially for fixture alignment and stock boundary interpretation

-

Improved user interface responsiveness and minimized crashes during long simulation runs

🎯 Why Choose VERICUT 9.5.3?

-

Reduce scrap, rework, and machine crashes

-

Optimize tool paths for faster, more efficient cutting

-

Verify real NC code—not just post-processed toolpaths

-

Simulate G-code, subprograms, macros, and complex logic

-

Work confidently with high-value parts and expensive materials

Whether you’re working in aerospace, automotive, defense, energy, or general precision manufacturing, VERICUT 9.5.3 empowers your team to achieve better results with less risk. It’s more than just simulation software—it’s a complete NC program validation and machining optimization system.