CADmeister 2021 cracked version

$ 150.00

Enabling concepts to take shape and out-of-the-box creation

Modern-day artisanal masters create new forms that transcend common sense and limitations.

We believe that supporting their uncompromising persistence is a mission of CAD/CAM systems of the future.

We will continue to challenge ourselves to develop further innovative technologies as the optimal partner for prominent contemporary artisans, tenaciously devoted to manufacturing, through CADmeister which enables them to conceptualize images that could otherwise never be discovered through an evolutionary approach.

Description

“CADmeister mainly help us to remove spring back. It is easy and fast to twist surface as needed. The result is more effective and beautiful than other software that ever used.

Before using PRESS FORM-EX of CADmeister. Due to the difference of surfaces’ shape, it is quite hard for operators because it need specific method for each surface type. By now we decrease working time from 1-2 days to 1 hour because of PRESS FORM-EX able to create smooth surfaces.”

Not only solving the intra-organization’s problems but Mr.Teerapong also advises Press Form-EX function of CADmeister to his supplier.

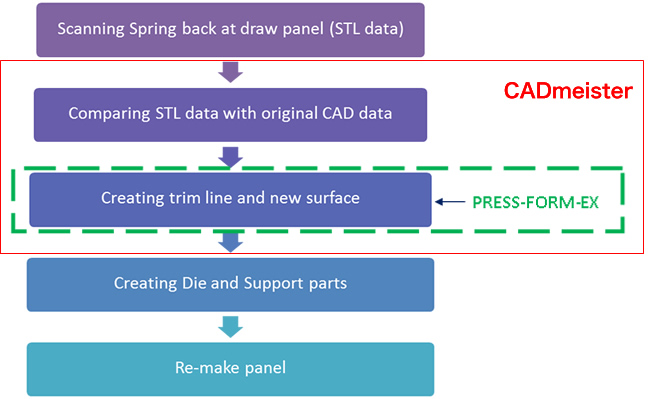

“In case of modify spring back at draw panel, scanning the model. The STL data (scanned data) is used to compare with original surface (CAD data). Later, use STL data and CAD data to create trim line and new surface in CADmeister. After that, creating jig and support parts. Next, do laser cutting refers to trim line. The trimmed part has high quality result. Finally do reverse engineering operation again by bending part. The result’s position is very much better.

From 1-2 days to only within 1 day, after using this idea with CADmeister. It’s much quicker. PRESS FORM-EX is extremely useful.”

CADmeister 2021 is designed to be easy to use.

In addition to standardizing and automating design, CADmeister 2021 supports the optimization of 3D design by linking

with IoT and analysis technologies.

By maximizing the benefits of 3D design, we can accelerate the shift to 3D in manufacturing and support highly efficient

design and stable quality without relying on worker skills.

CAD Capabilities

BASE/ADVANCE (Support for modelling)

CADmeister, a hybrid modeler capable of operating wire frame models, surface models, and solid models, performs set operations of mixed data of surface model and solid model, and enables modeling environments that are freed from the restrictions due to the differences in the types of data models.

STL-EDIT (Tool for editing STL figures)

STL-EDIT consists of a batch of editing functions. It enables the use of STL figures that have been measured through 3D co-ordinate measuring instruments and imported into CAD system.

DATA EXCHANGE (Data exchange tool)

CADmeister is equipped with various types of strong tools for data exchange that enable highly accurate exchanges of data with various types of CAD system.

HEALING SP (Automatic CAD data correction)

This function allows you to correct and merge separated and overlapping surfaces with a single click.

MODEL-COMPARISON SP (Model comparison)

This function compares the model before and after design changes and displays the changes in a list or temporary graphic.

FILLET-REMOVAL SP (Fillet removal)

This function deletes the fillet face of the product data and returns it to a right angle.

PRESS DIE

PRESS (Support for designing press dies)

The module supports designing press dies. It consists of three key function items: design support, modeling support, and post-process support.

CAE-PRESS (Support for stress analysis)

This module is for a stress analysis which enables seamless operations between CAD and CAE for designers. Designers can perform stress analyses through simple input CAD operation without being concerned with CAE.

PRESS-SIM (Support for creating Blank Deployment Lines and Flange Deployment Lines)

This is a simple simulation capability for shaping a press die. This enables a quick understanding of ‘Blank Deployment Lines’ and ‘Flange Deployment Lines (Trim Deployment Lines)’ that will help quotations at the initial stage of designing.

DL (Die layout design support)

DL enables three-dimensional supports. It is used for the design stage for improving quality of DL design

FORM-EX (Support for modeling and forming)

This enables quick and precise modeling in order to help users shorten the delivery time.

It can form and model by taking into consideration the characteristics of press die forming, empty-weight deflection (that is needed for confirming interference against die parts when transferring panels), material characteristics, and STL figures.

PRESS-FORM-PLUS-II (Reverse engineering support)

PRESS-FORM-PLUS-II enables direct references to the results of simulation analyses of sheet metal forming (in the form of NASTRAN format file) in order to improve the preciseness of forming at the initial stage.

DRAW-DIE-EX (Navigation tool for the Draw method of die designing)

DRAW-DIE-EX can shorten a designing phase through the use of Dynamic Navigator, navigation tool, regardless of the skills of individual users.

PRESS-MOTION (Tool for analyzing the transfer statuses of production process)

PRESS-MOTION enables designers to analyze transfer lines through simple operations.

CADmeister-LITE (Tool for Confirming the CAD Attribute Data)

This is a tool for confirming the attribute data that have been assigned to 3D CAD data (such as the information of materials and unit prices).

MOLD

MOLD CREATOR (Support for designing of molds)

MOLD CREATOR can be used for each phase of structuring a mold: initial design consideration, considerations of cavity and core, conceptual design, detailed design, creation of drawing, preparation of data for order placement.

CADmeiser-LITE (Tool for confirming CAD attribute data)

CADmeister-LITE enables users to input directly CAD attribute data (part attributes, machining attributes, and tolerance attributes) that have been provided to groups of parts and individual parts, provided that the parts have been designed through the use of MOLD CREATOR.

MOLD-FORM (Support for forming molds)

MOLD-FORM enables designers to rectify poorly shaped portions of resin models partly due to sink and warpage through the use of the simulation results of shaping.

CAE-MOLD (Analytical tool for resin mold designers)

CAE-MOLD presents a collection of seamlessly integrated CAD and CAE functions such as analysis of mold cooling and analysis of mold bend. CAD shapes can be used as they are on the CAD system screen. Professional CAE expertise or skills are not needed to execute the functions.

CAE-INJECT (Resin flow analysis tool)

CAE-INJECT enables resin flow analyses by utilizing CAD shapes on the CAD screen as they are without data conversion. Also, it enables confirmation of results through the same operation of CAD commands. Thus, this tool enables mold designers to improve the accuracy of judgment and shorten the lead time.

CAE-EJECT (Demolding Analysis)

We have released a command that can analyze the temperature distribution and contact force distribution of the product during mold release and analyze the load on each ejector pin. This can be used as a reference when examining the number and location of ejector pins.

DENKYOKU-CAD (Support for creating electrode shapes)

DENKYOKU-CAD provides a full support for all phases of: creating mold, considerations and shaping of electrode parts, and preparing documented instructions in order to perform electric discharge.

CAM

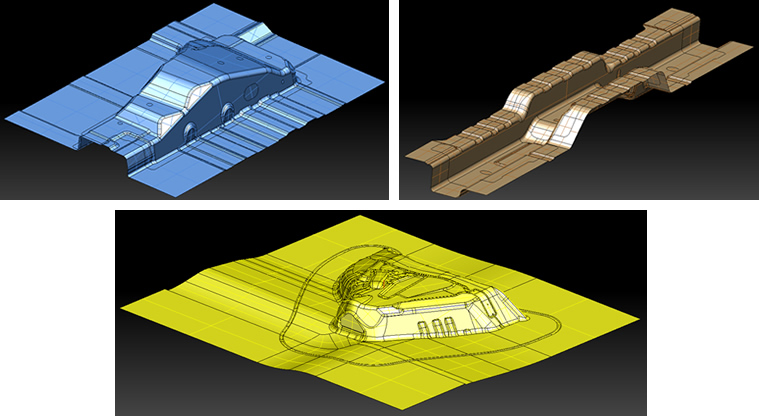

CAM3D (3D CAM System)

CAM3D creates data for machining curved surfaces of 3D CAD models that consist of surfaces as well as solids.

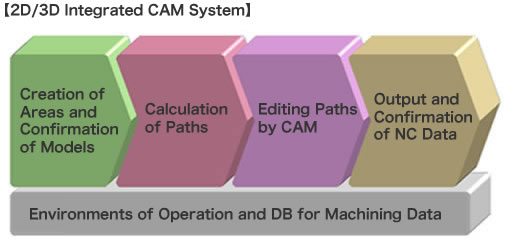

Basic Functions of CAM (Environments of Operation and DB)

CADmeister/CAM provides operational modes for skillful expert users and beginners.

Basic Functions of CAM (Output and Confirmation of NC Data)

Capabilities of creating NC Data that support ‘3-axis machining devices’ , ‘Table 5-axis machining devices’ , and ‘Attachment 5-axis machining devices’ are provided.

CAMEDIT (CAM Editing Capability)

CAMEDIT has various types of editing capabilities. It enables users to edit paths highly efficiently through easy operations.

CAM2D (Hybrid 2D CAM)

CAM2D is capable of seamlessly integrating the features of CAD and CAM systems. It enables users out in the manufacturing field to create 2D machining paths which are used for the commands of ‘Profile Machining’ , ‘Pocket Machining’ , and ‘Hole Machining’ through simple operations.

CAM-DX (Enhanced CAM functions)

CAM-DX supports high-speed and high-quality machining methods as well as the conventional machining methods. Thus, CAM-DX can respond to a wide variety of users’ needs.

CAM-ADV (Advanced CAM functions)

CAM-ADV enables work flows without wastes and reworks, provided that it is operated as an add-on function for CADmeiser/CAM.

3DPROFILE (3D profile machining)

3DPROFILE has various 3D capabilities of machining and interference prevention. It supports automatic profile machining from preliminary rough processing through to finishing.

CAM-STL (CAM system for STL models)

CAM-STL creates paths on the basis of STL figures such as measurement results and models that consist of combinations of surfaces and solids.

CAM-STRUCTURE (CAM system for machining a ferrous die for accepting a press die)

CAM-STRUCTURE is capable of creating data for machining a ferrous die for accepting a press die through simple operations on solid data. (Note that the ferrous die is referred to as a ‘Structure’ and the press die is referred to as an ‘Insert’.) CAM-STRUCTURE improves the precision of machining a Structure and reduces workloads.

FM-CAM2 (Full-Mold CAM)

FM-CAM2 is a support tool for processing full-mold models through an effective use of 3D solid models.

CAM-ATTRIBUTE (CAM for coordinating attribute data)

CAM-ATTRIBUTE automatically creates and standardizes data for hole machining based on the 2D/3D attribute data and geometric data that have been assigned for hole machining.

DENKYOKU-CAM (CAM for machining electrode parts)

DENKYOKU-CAM provides a one-stop support for all the phases from CAM calculation through to interference check after NC (numerical control) output. This is enabled by an intuitive operation of dragging attribute data that have been given to electrode models and dropping them to a subject database for machining.

Other Function

IoT-Visualization (IoT visualization for tooling)

It is now possible to superimpose pressure and other sensor information about mold and press dies onto CAD data. By visualizing information about molds, the system supports the entire lifecycle of molds, from the design process to maintenance.

JIG-PKG (Support System for Designing Inspection Jigs)

JIG-PKG optimizes the design and manufacturing of inspection jigs.

It provides enhanced functions dedicated to inspection jigs by utilizing the strong modeling functions of CADmeister.

3D LASER (3D Laser Machining System)

This offline teaching system enables users to create NC (numerically controlled) programs and jigs for simultaneous 5-axis laser machining using the minimum workload through the use of 3D CAD data.

G-Quality (Programming System for Automatic Measurement by 3D measuring instruments)

This CAD offline teaching system enables users to code programs for automatic measurement through the use of 3D measuring instruments.

Data File Management Function

The management of all data pertaining to design and manufacturing can be integrated.

The subject data include the data of CADmeister, various types of document files, and other CAD/CAM system data files.