Description

IPSEpro’s modules are used to:

- Calculate heat balances and predict design and off-design performance.

- Verify and validate measurements during acceptance tests.

- Monitor and optimize plant performance on-line.

- Plan modifications and upgrades of existing plants.

Ready-to-use solutions are available for a wide range of applications:

- Thermal Power

- Geothermal Energy

- Concentrating Solar Power

- Desalination

- Refrigeration

- Flue Gas Cleaning

- Biomass Gasification

Unlike with other programs, IPSEpro users are not restricted to predefined models and model libraries. Ready-to-use model libraries are available, but can be adapted to specific needs as well. New model libraries can be created easily created by users, which makes IPSEpro the perfect tool for creating proprietary solutions.

The core of IPSEpro embeds a highly flexible modeling system for calculating heat balances and for simulating processes. IPSEpro goes far beyond the capabilities of other available heat balance programs. IPSEpro’s Model Development Kit introduces a unique level of flexibility by allowing you to create new component models or create completely new model libraries.

You can use IPSEpro for quick process assessments, detailed engineering, design, retrofitting, repowering, and acceptance testing. Its component-level flexibility and component-by-component approach allows you to model virtually any type of system.

IPSEpro covers as the entire lifecycle of a process plant from conceptual design to plant operation. There are great advantages of using with IPSEpro a single software solution rather than isolated products throughout the lifecycle of a plant:

- One single model can be used throughout the lifecycle.

- The use of the same calculation engine and mathematical methods ensures consistent results.

- One common interface for all purposes facilitates the usage.

Overall Advantages in using IPSEpro:

- Short implementation time

- Users need not to be computing specialists

- A uniform environment for a wide range of problems

- New components are easily integrated in an existing system

- The user can concentrate on the physical background of his/her problem

- State-of-the-art numerical methods

- Comfortable graphical user interface without extra costs

- Low maintenance costs

Applications

Based on IPSEpro SimTech offers ready-to-use solutions for various fields of application. This includes solutions for:

Desalination

Shortage of fresh water has become one of the major challenges for societies all over the world. Water desalination offers an opportunity to significantly increase the freshwater supply for drinking, industrial use and irrigation. Over the last decades seawater desalination has become an important source for potable water for many arid regions.

To guarantee affortable supply of water through desalination the demand for the construction of efficent and economic desalination plants is growing continuously. Reliable performance models are essential for developing efficient plants. IPSEpro is the ideal tool for creating performance models and for using them to design efficient plants.

Geothermal Power

Geothermal energy is a clean, renewable and inexhaustible source for producing power. However, the thermal efficiency of geothermal power plants is low, because geothermal fluids do not reach high temperatures. This makes it important to find the best process layout and the best working fluid for the power plant process. For selecting the optimum plant for a given geothermal site accurate performance models of the possible options play an important role.

IPSEpro is the ideal tool for creating performance models of any plant type used for geothermal power generation.

Refrigeration

The challenge of refrigeration processes is to create the cooling capacity using the lowest possible amount of energy. This is achived by identifying the optimum process but also by integrating the processes in the best way with other processes.

IPSEpro models provide valuable information about the appropriate process design for refrigeration processes.

Concentrating Solar Power

Concentrating solar power plants are system useing established technology that is readily available. In comparison with photovoltaic systems they have the advantage that by storing thermal energy their production profile can match the demand profile.

In order to commercially compete with photovoltaic systems, CSP plants must be optimally designed. For this purpose IPSEpro performance models have enormous value.

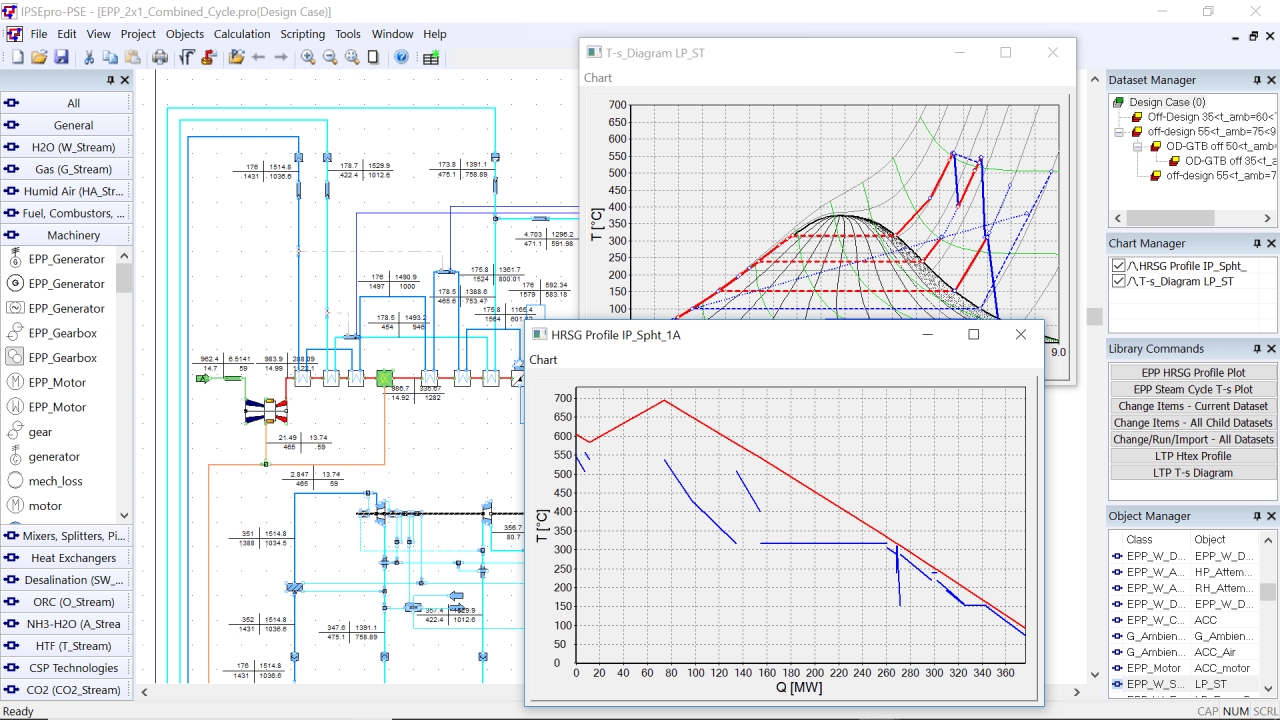

Thermal Power

Today’s business and operational requirements for thermal power plants are significantly more complex than ever before. Unstable fuel costs and demand for higher operational flexibility together with increasing environmental constraints are challenges for any thermal power plant project. Precise planning is essential for new or modified power plants.

A reliable heat balance and performance model is a key factor for any successful thermal power plant project: At early project stages it is necessary to determine whether and how the performance requirements can be achieved. At later stages in serves for identification of operational limits and to determine optimum operating points.

IPSEpro is the ideal platform for creating heat balance and performance models for thermal power plants.

System Description

Many engineering systems have the structure of a network of discrete components that are connected appropriately. Such a network may represent, for example, a power plant or a network of heat exchangers. It may also represent equipment that is split into smaller elements. Mathematically, these networks are represented by systems of equations. IPSEpro is a powerful environment that allows to set up models of such networks graphically and to solve them.

The sophisticated and yet intuitive modeling concept is the foundation of IPSEpro’s power.

IPSEpro Architecture 1

IPSEpro is based on the concept of “standardized” components that are used to build the model of a complete process. Each model is mathematically represented by a set of equations and variables. To build the mathematical model of a process means to join all equations of the component models into a single system of equations.

IPSEpro provides efficient data management, powerful mathematical methods, and an intuitive graphic interface (based on Windows) so that the user can fully concentrate on the technical aspects of his problems.

How to use IPSEpro ?

The key to IPSEpro’s flexibility is its concept of model libraries: IPSEpro is adjusted to a specific area by loading an appropriate model library. Since the user can create his own libraries, there are virtually no limits to the application of IPSEpro. Thus, IPSEpro allows flexibility at two levels: at the component level and at the process level.

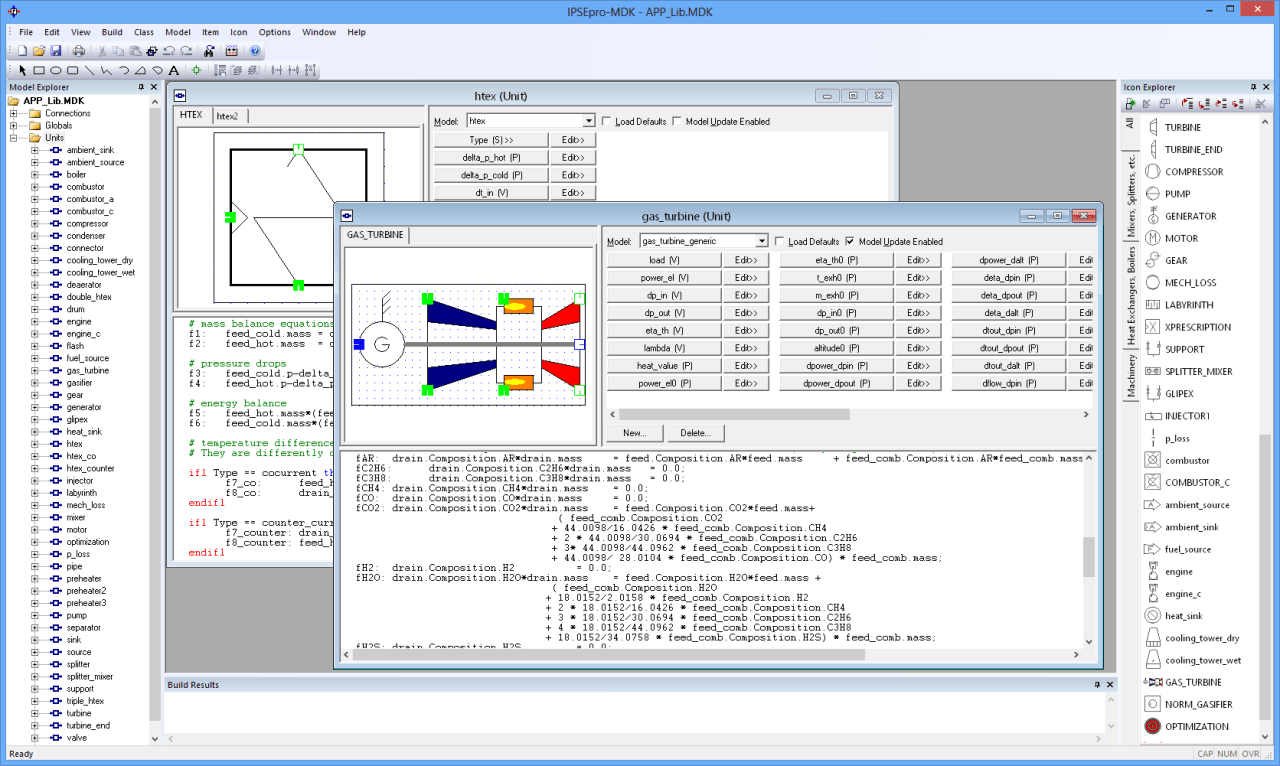

IPSEpro’s Component Level Flexibility

IPSEpro provides unlimited flexibility in defining the characteristics of the component models that are used for modeling processes. This allows the user to build component model libraries that exactly match his application requirements.

The component model building process is easy and interactive. The user designs his models mathematically and graphically within MDK, IPSEpro’s Model Development Kit.

The user can also modify and customize existing component models from standard model libraries, using MDK, if required.

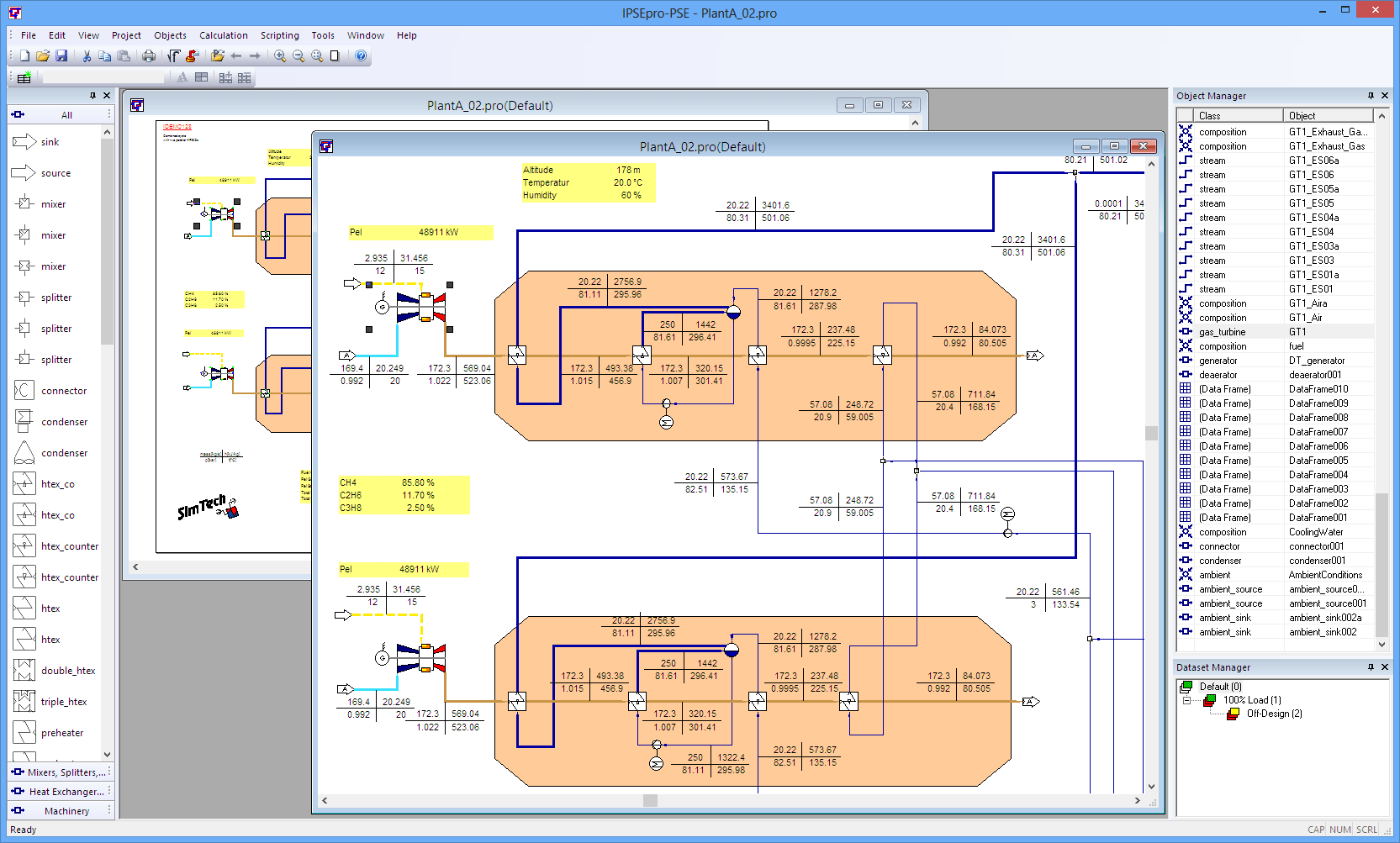

IPSEpro’s Process Level Flexibility

IPSEpro allows complete freedom in arranging the available components in order to represent a process scheme. A graphical user interface facilitates and accelerates substantially the development of process schemes, and the presentation of the results of calculations.

To set up a process model, the user chooses component icons from a library menu, places and connects them appropriately in the project window of PSE, IPSEpro’s Process Simulation Environment. Numerical data and results of process calculations are entered and displayed directly in the project window.

IPSEpro allows the user to simulate the behavior of single elements of processes, of parts of a process and of models of complete plants. IPSEpro provides efficient data management, and uses robust algorithms that devise extremely short calculation time.

IPSEpro’s Structure

The structure of IPSEpro with its main modules MDK and PSE has the advantage that the flow of data is well defined.

In a production environment, the models in a library typically represent an established modeling standard . Modifications of the models in library may have far reaching consequences. Changes should therefore only be made by authorized and qualified users. This is achieved by restricting the usage of MDK to these authorized users.

Frequently the author of a model library is different from the actual user of the library. The user of the library will then only use PSE, so that accidental changes of the library are not possible.

It is possible to compare a model library with a program written in a traditional programming language. Only one or few qualified persons have access to the source code, while a much larger number of persons are using the executable code.

In research and development, model libraries are considerably more dynamic. Therefore users should have full access to both PSE and MDK.

Major IPSEpro modules

IPSEpro has a modular structure, so that the requirements of a specific configuration can easily be taken into account. With its two major configurations: the Design Suite and the Plant Operation Suite, IPSEpro covers the entire lifecycle of a process plant. The main modules of IPSEpro are listed below. Find out more about them!

- MDK – Model Development Kit

- PSE – Process Simulation Environment

- PSServer – On-Line Module

- PSOptimize – Optimization

IPSEpro versus solutions using traditional programming languages

IPSEpro has proved to solve efficiently a wide range of modeling problems that would otherwise require coding in a traditional programming language like FORTRAN or BASIC. Using IPSEpro instead of other directly coded solutions with traditional programming languages has a series of benefits.

IPSEpro Design Suite

IPSEpro is a highly flexible software environment for calculating heat balances and simulating processes, which can be used in various fields of application like power plant engineering, chemical engineering and other related areas. IPSEpro Design Suite concerns a set of configurations of the system mainly dedicated to process modeling and optimization.

IPSEpro Design Suite allows you to create process model graphically by appropriately connecting component models from a library. Customized component models can be easily built using IPSEpro’s Model Development Kit, to integrate the model library used by your application project. IPSEpro provides efficient data management, powerful mathematical methods and an intuitive graphic user interface, so that you can fully concentrate on the technical aspects of your models. With virtually unlimited flexibility, IPSEpro Design Suite allows you to modify existing component models or to create your own customized ones in order to meet exactly your modeling requirements.

Major Modules of the Design Suite

|

|

|

Plant Operation Suite

An Overview of the IPSEpro Plant Operation Suite

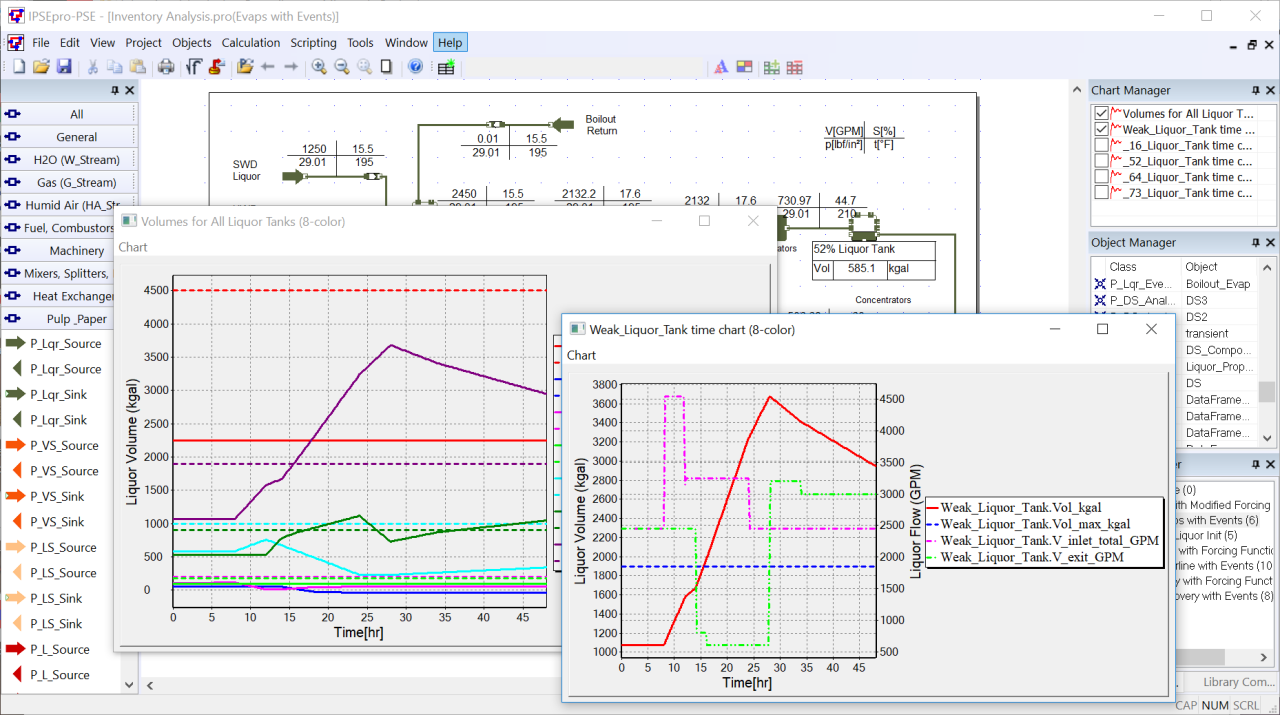

IPSEpro Plant Operation Suite is an on-line performance monitoring and optimization system that is fully integrated into the IPSEpro framework of applications.

By using IPSEpro Plant Operation Suite you are able to predict the most profitable way to run your plant, and to measure and track plant performance changes. IPSEpro Plant Operation Suite is highly flexible and customizable so that it can be efficiently adjusted for a wide range of applications.

IPSEpro Plant Operation Suite Features:

- Models exactly tuned for your plant’s requirements, due to IPSEpro’s capability to create and modify component models.

- Seamless integration with virtually any plant data management (PDM) system, including OSIsoft’s PI and proprietary PDM systems on the basis of Oracle and Sybase databases.

- Optimization based on physical plant models.

- Data Validation.

- Sharing of plant models with off-line system for investigation of “What-if” scenarios.

Major Modules of the Plant Operation Suite

|

|

|

IPSEpro Plant Operation Suite offers you the following benefits:

- Enhanced profitability by providing optimum values of operating parameters.

- Improved performance through the identification of degradation.

- Identification of faulty sensors and inconsistent measurements.

- Increased reliability through better knowledge of your plant’s operation.

Plant Operation Suite Deployment

According to your preferences, we can install a completely configured Plant Operation Suite or we can customize the Plant Operation Suite together with your performance engineers and operating staff.

Check about the Program Modules that you can use in the IPSEpro Plant Operation Suite.

Contact us today for further information about IPSEpro Plant Operation Suite!

IPSEpro Program Modules

IPSEpro covers the entire lifecycle of a process plant with its two major configurations: the Design Suite and the Plant Operation Suite. IPSEpro has a modular structure, so that the requirements of a specific installation can be taken into account.

IPSEpro’s Modules are mainly used to:

- Calculate heat balances and predict design and off-design performance. (Design Suite Configurations)

- Estimate costs during conceptual design.(Design Suite Configuration with PSEconomy)

- Verify and validate measurements during acceptance tests.(Design Suite Configuration with PSValidate)

- Monitor and optimize plant performance on-line.(Plant Operation Suite)

- Plan modifications and repowering of existing plants.(Design Suite Configurations)

Major IPSEpro modules:

- MDK – Model Development Kit

- PSE – Process Simulation Environment

- PSServer – On-Line Module

- PSOptimize – Optimization

Check about all the available Program Modules listed in the side menu and contact us today for testing IPSEpro at your convenience!

Model Libraries

Ready-to-use IPSEpro model libraries are available for various fields of application

APP_Lib: Advanced Power Plant Library

Advanced Power Plant Library for modeling of a wide range of thermal power systems

GT_Lib: Gas Turbines Library

Commercial gas turbines library

LTP_Lib: Low Temperature Process Library

Organic Rankine Cycles (ORC) and Kalina Cycles

CSP_Lib: Concentrating Solar Power Library

Concentrating solar power process modeling

Desal_Lib: Desalination Process Library

Desalination plant modeling, supports all major desalination technologies

Frigo_Lib: Refrigeration Process Library

Compression and absorption refrigeration and heat pump process modeling

FGC_Lib: Flue Gas Cleaning Library

Modeling of flue gas cleaning systems

PGP_Lib: Pyrolysis and Gasification Process Library

Library for modeling biomass gasification systems