Pegasus cad-cam STONE 2024 R2 cracked release

$ 220.00

Explore the capabilities of our software dedicated to stone and marble processing.

The versatile capabilities of Pegasus cad-cam software solutions allow their use in multiple contexts, ranging from small workshops to large stone and marble processing companies…

Description

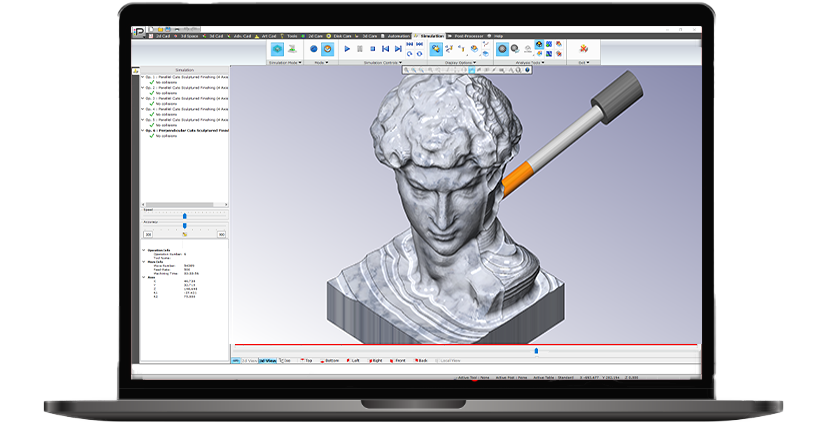

Software versions for stone and marble processing with 3/5 axis machine or anthropomorphic robots. The product’s features allow it to be used in a variety of contexts, from small artistic workshops to big companies producing kitchen and bathroom tops.

Software versions.

Software versions for programming machining operations on turning centres with up to 6 continuous axes. Simple and intuitive version, it needs no advanced technical skills to use.

![]() download the brochure

download the brochure

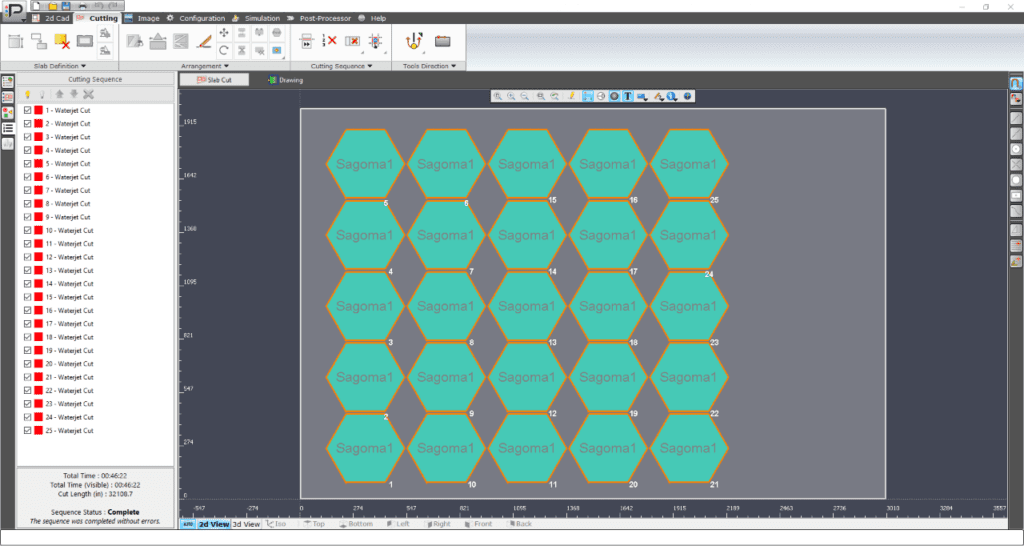

Bridge milling module with a complete set of functions for cutting and slab sectioning. Designed to be installed on the machine or in the office, it allows shape drawing and design, slab qualification, nesting and cutting operations integrated in one easy-to-use solution.

![]() download the brochure

download the brochure

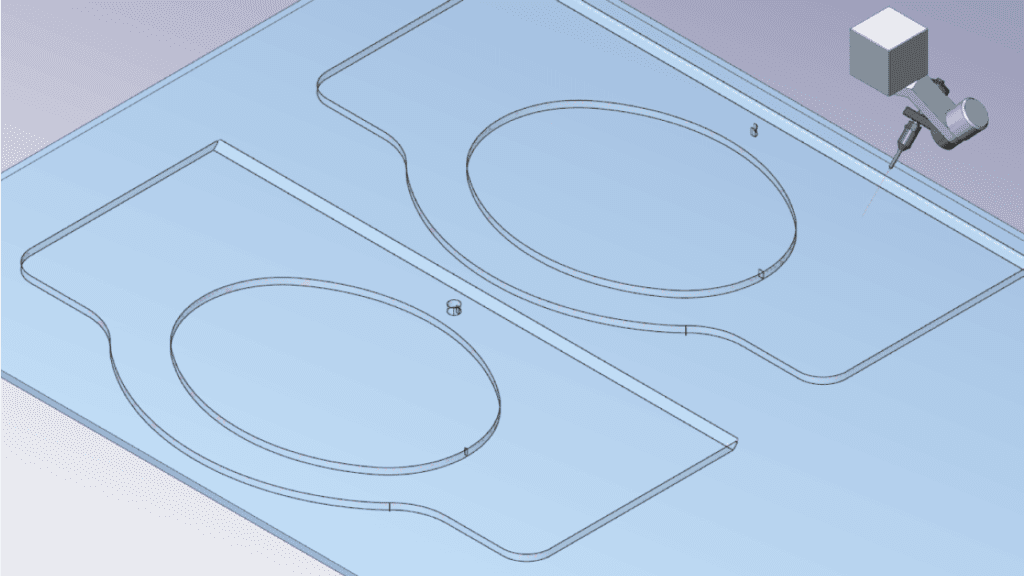

Dedicated module for modelling and processing kitchen tops, bathroom tops and other types of technical objects. Design, CAM and simulation are integrated in a single solution.

![]() download the brochure

download the brochure

Software versions for stone and marble processing with 3 and 5-axis waterjet machines. Vertical edge or constant bevel machinings and variable bevel machinings are supported.

![]() download the brochure

download the brochure