C.B.Ferrari TS85 CAM full cracked release

$ 200.00

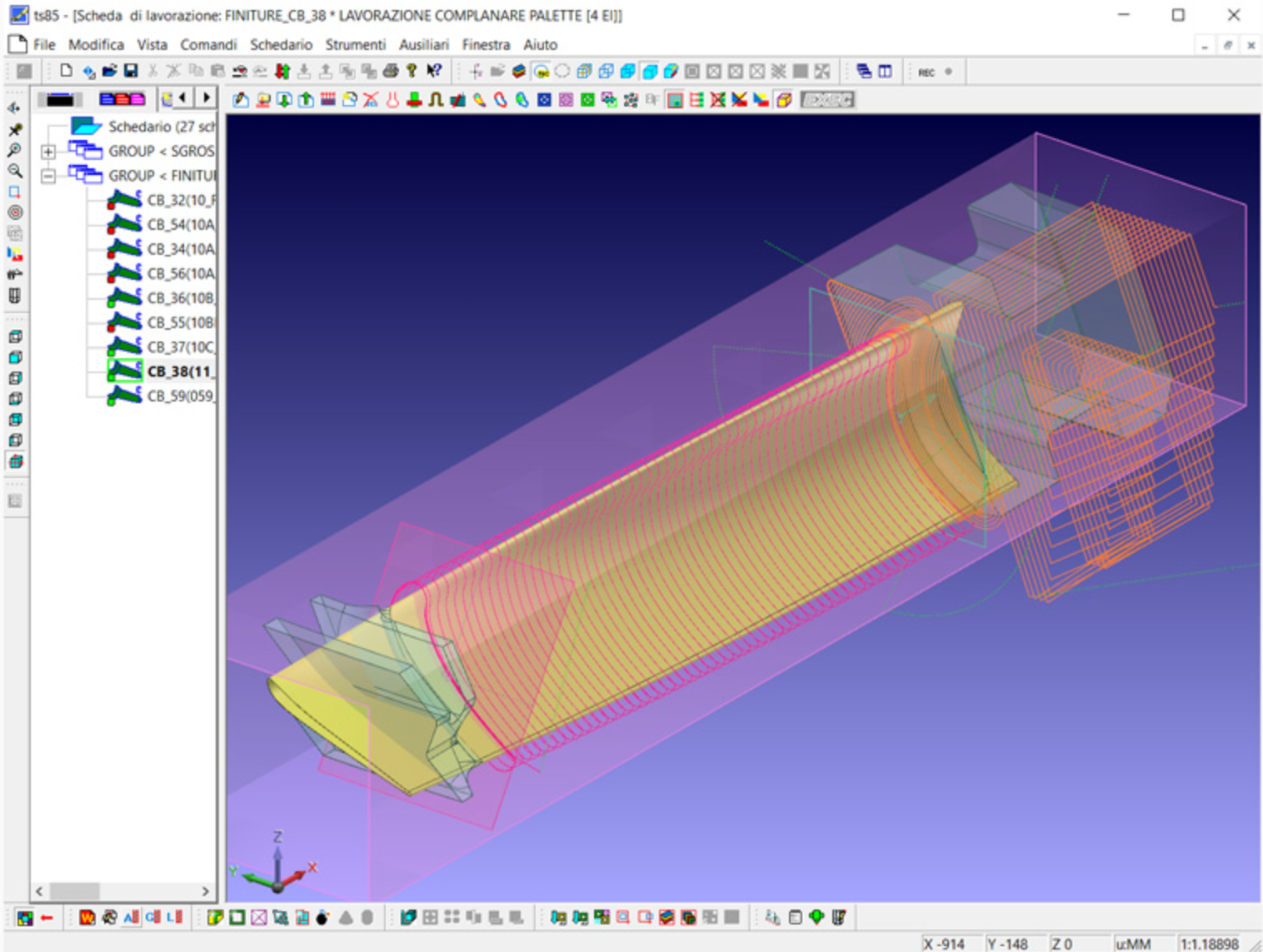

TS85 by C.B. Ferrari, a cutting-edge CAM software engineered for precision 5-axis machining of intricate sculptured surfaces, including turbine blades, compressor blades, and Integrally Bladed Disks (IBRs). Designed for aerospace, energy, and high-tech industries, TS85 combines a robust geometrical database with versatile machining strategies—roughing, semi-finishing, and finishing—to streamline production of complex parts like airfoils and platforms. Integrated seamlessly with C.B. Ferrari’s 5-axis systems, this software boosts efficiency, reduces costs, and delivers top-tier accuracy for OEMs and suppliers. Elevate your manufacturing with TS85’s advanced toolpath optimization and blade-specific features…

Description

TS85 by C.B. Ferrari: Advanced CAM Software for Precision 5-Axis Machining

Discover TS85 by C.B. Ferrari, a cutting-edge CAM software designed for 5-axis machining of complex sculptured surfaces, tailored specifically for blade manufacturing in the aerospace and energy industries. This sophisticated software empowers manufacturers to craft intricate components like turbine blades, compressor blades, and Integrally Bladed Disks (IBRs) with exceptional precision and efficiency, making it a game-changer for high-tech production environments.

New Functions

The latest version of TS85 introduces powerful enhancements to streamline your workflow:

- Dedicated Milling Strategies for IBRs: Tackle the complexities of Integrally Bladed Disks with specialized toolpaths, ensuring flawless execution of even the most challenging designs.

- Mid-Spans and Edge Profiles Machining: Enhanced features deliver greater accuracy for critical blade sections, improving overall component quality.

- Automatic Roughing Cycle: Simplify your process with a one-step toolpath generation—just select the blade model and define the blank profile for an optimized roughing strategy.

- Platform Machining with Tool Radius: Achieve superior stability and precision during platform operations, a vital upgrade for precision machining.

These updates make TS85 an indispensable tool for manufacturers aiming to stay ahead in 5-axis CAM technology.

Highlights

TS85 stands out as a premier solution for blade manufacturing and beyond:

- Geometrical Database: Seamlessly manage complex surface data, supporting both in-software creation and imports via formats like IGES or STEP.

- Machining Strategy Database: The heart of TS85, this feature generates optimized toolpaths for roughing, semi-finishing, and finishing of airfoils, platforms, and other intricate parts.

- Specialized for Complex Surfaces: Perfect for producing turbine blades, compressor blades, and turbo machinery parts with speed and cost-efficiency.

- Industry-Leading Integration: Designed to work hand-in-hand with C.B. Ferrari’s 5-axis machining systems, ensuring a unified and powerful production ecosystem.

These highlights position TS85 as a top choice for aerospace components and energy equipment manufacturing.

System Requirements

While specific requirements for TS85 depend on your unique setup, this high-performance CAM software typically demands:

- Processor: Multi-core CPU for fast computation of complex toolpaths.

- Memory: 16GB RAM or higher to handle large CAD/CAM files.

- Graphics: A dedicated graphics card to support detailed visualizations.

- Storage: Ample space for storing extensive design and machining data.

- Operating System: Compatible with modern Windows platforms.

For optimal performance in 5-axis machining and toolpath optimization, a robust workstation is recommended to unlock TS85’s full potential.

Bug Fixes

While specific details on recent bug fixes are not widely publicized, C.B. Ferrari consistently refines TS85 to enhance reliability and performance. Updates focus on improving usability and ensuring seamless operation across its advanced features, keeping your blade manufacturing processes running smoothly.

Benefits for Your Industry

TS85 accelerates production timelines and reduces costs, making it ideal for:

- Aerospace: Craft turbine blades and compressor blades with unmatched precision.

- Energy: Produce durable components for power generation systems.

- High-Tech Manufacturing: Excel in environments where complexity and accuracy are non-negotiable.

Its tailored milling strategies and toolpath optimization ensure that even the most intricate airfoils and turbo machinery parts meet the highest standards.

Why Choose TS85?

Elevate your manufacturing prowess with TS85 by C.B. Ferrari, a CAM software that blends innovation with practicality. Whether you’re machining complex surfaces for aerospace or energy applications, TS85 delivers efficiency, quality, and integration with C.B. Ferrari’s 5-axis systems. Stay competitive with a solution that anticipates industry demands and drives excellence in precision machining.

Unlock the future of 5-axis CAM for aerospace components and efficient machining of complex surfaces with TS85—your key to superior blade manufacturing.