VISI 2024.4 CAD/CAE/CAM full cracked version released

$ 170.00

VISI CAD/CAM software by Hexagon is a leading PC-based solution for mold and die industries, offering integrated wireframe, surface, and solid modeling. With advanced tools like VISI Modelling, VISI Mould, and VISI Flow, it streamlines 3D tool design, plastic flow analysis, and high-speed machining (2D, 3D, 5-axis). Ideal for automotive and aerospace tooling, VISI enhances precision and productivity…

Description

VISI 2024.4, the latest release from Hexagon, brings a host of new functions and enhancements designed to elevate the CAD/CAM experience for mold and die professionals. This version builds on VISI’s reputation as a leading PC-based software for tool design and manufacturing, introducing advanced automation, improved usability, and precision-focused tools across its modeling, simulation, and machining capabilities. Below is a detailed breakdown of the standout new features in VISI 2024.4, tailored to streamline workflows and boost productivity for users in industries like automotive, aerospace, and consumer goods.

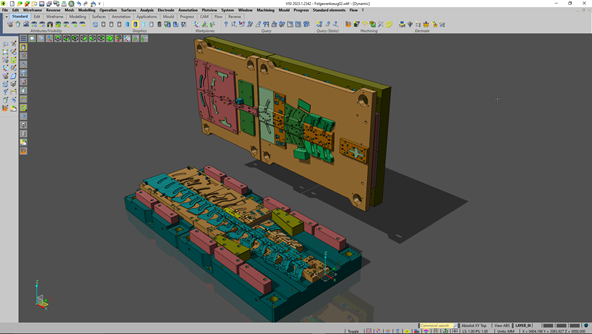

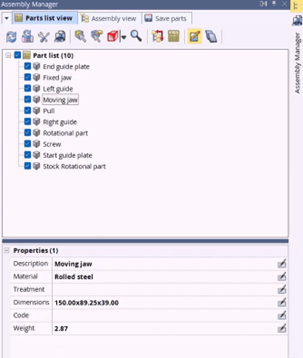

One of the headline additions is the Assembly Manager Automation, a powerful tool that simplifies managing complex assemblies. This feature automates updates to function fields such as weight, bounding box, and volume, linking them to a shared material database. This integration ensures consistent data accuracy across projects, reducing manual input errors and saving time. For toolmakers juggling multiple components, this automation enhances workflow efficiency by keeping critical assembly data synchronized without repetitive adjustments.

Another significant upgrade comes in Layer Management, which has been overhauled for greater flexibility and ease of use. Users can now reallocate layers to different grid positions, manage groups more effectively, and navigate a simplified interface. The revised dialog box removes previous constraints tied to plot view pages, offering a more intuitive way to organize and access layers. This is especially useful for complex projects where precise layer control is essential, making it easier to maintain clarity and structure throughout the design process.

Drafting Improvements also take center stage in VISI 2024.4, with new commands tailored to refine model preparation. The introduction of circular bending commands enhances the ability to design curved features accurately, while improved finishing attribute assignments ensure better surface quality definitions. Updates to reverse surface modeling further streamline the process of working with scanned or imported data, allowing users to create editable models more efficiently. These enhancements collectively reduce prep time and improve the transition from design to manufacturing.

On the CAM side, VISI 2024.4 refines machining operations with a focus on usability and automation. The Add Operation Window has been redesigned to make toolpath selection more straightforward. Toolpaths are now grouped into Standard, Expert, and Superseded categories, reducing clutter and helping users quickly find the right strategy. The “Reference Name” feature, extended by the “CAD Change Attribute,” now applies to all subsequent CAM geometries (such as profiles, pieces, stock, and obstacles), laying the groundwork for deeper automation in machining workflows. This ensures consistency and traceability across operations.

For multi-axis machining, the 3to5 Management feature automatically relinks 3-axis input toolpaths to their 5-axis counterparts, preserving all connections when transitioning between strategies. This seamless integration minimizes manual rework and enhances flexibility, particularly for complex parts requiring multi-axis precision. Additionally, the new Send to CAM command replaces and expands the previous “Run Machining Strategist” function, enabling users to export geometry not only to Machining Strategist but also to WORKNC and ESPRIT. This broadened compatibility enhances VISI’s interoperability with other Hexagon solutions, catering to diverse shopfloor needs.

The user interface for CAM operations has been consolidated and simplified, displaying only the parameters relevant to the selected strategy. This reduces unnecessary clicks and streamlines decision-making. Users can also track which operations are tied to specific geometries directly from the Model Manager, lowering the risk of errors or unintended changes. For machining efficiency, the Improved Stock Analyser now identifies residual material after a single toolpath, enabling quicker adjustments to optimize the process.

In 2.5-axis pocketing, a new option automates the ordering of nested group features, minimizing lift-offs and rapid movements. This results in faster cycle times and reduced wear on tools, a practical boon for high-volume production runs. Meanwhile, the updated CAM-Engine unifies roughing, waveform, and global-roughing strategies under one intuitive interface. This unified approach extends toolpath reliability, particularly when using face lists for waterline and raster strategies, ensuring smoother execution across varied geometries.

With over 150 enhancements in VISI 2024.4, these new functions collectively aim to simplify workflows, enhance precision, and empower innovation. From automated assembly management to refined machining strategies, this release reflects Hexagon’s commitment to addressing the real-world needs of toolmakers. Whether you’re designing intricate molds or optimizing CNC operations, VISI 2024.4 delivers tools that make the process faster, smarter, and more reliable. Anything specific about these updates you’d like me to expand on?

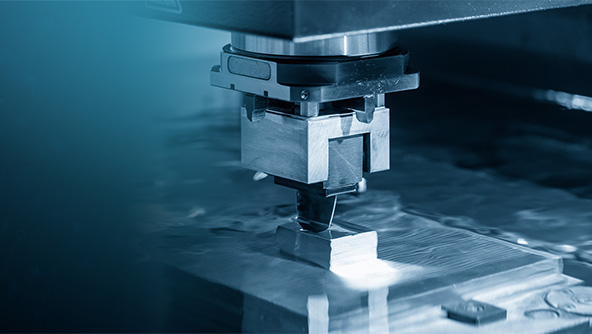

VISI Modelling

VISI Modelling provides a robust and powerful solid and surface modelling system for mould and die.

VISI Analysis

VISI Analysis provides mould and die manufacturers with solutions for the validation and preparation of model geometry.

VISI Mould Design

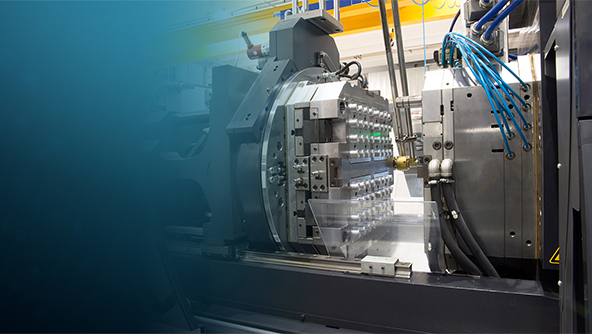

VISI Mould Design provides a complete mould tool design solution that guides the user through the mould development process.

VISI Flow

VISI Flow is ideal for pre- and post-production analysis and concurrent engineering of injection moulded plastic components.

VISI Electrode Design

VISI Electrode Design is an automated module for the creation and management of electrodes and their holders.

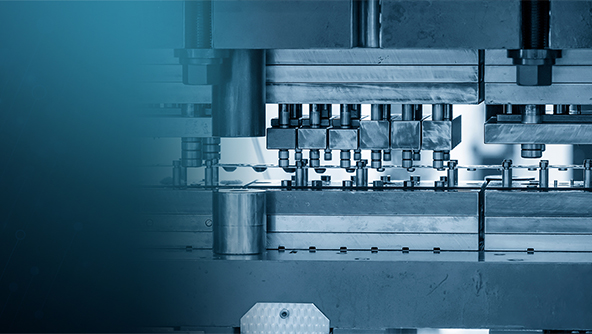

VISI Die Tool Design

VISI Die Tool Design provides users with dedicated solutions for progressive die design and press tools.

VISI Blank

VISI Blank is an integrated solution for the development of 2D blank shapes from complex 3D models.

VISI Reverse

VISI Reverse enables users to create fully compatible editable solid models from scanned data.

VISI 2.5 Axis Toolpath

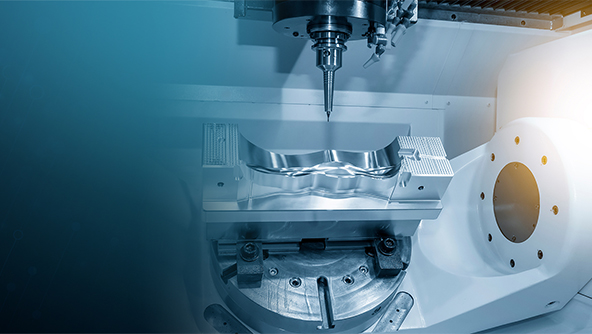

VISI 2.5 Axis Toolpath provides a practical, intuitive and simple solution for CNC programming, including 4- and 5-axis indexing.

VISI 3 Axis Toolpath

VISI 3 Axis Toolpath creates intelligent toolpaths on the most complex 3D parts.

VISI 5 Axis Toolpath

VISI 5 Axis Toolpath has been regarded as advanced technology best suited to the aerospace and automotive industry.

VISI PDM

A modern PDM system to make your development processes more efficient.

Experience the latest advancements in CAD/CAE/CAM with VISI 2024.4. This release brings enhanced efficiency, precision, and automation across modelling, simulation, and manufacturing.

1. Modelling Enhancements

- Assembly Manager Automation:

Automate updates to function fields, such as weight, and associate them with specific functions like bounding box and volume. This feature integrates seamlessly with a shared material database, streamlining workflows and ensuring data accuracy across projects.

- Layer Management:

Enhanced layer organization allows for flexible reallocation of layers to different grid positions, improved group management, and simplified functionality for better usability. The revised dialog box eliminates constraints tied to plot view pages, enabling more intuitive layer handling. - Drafting Improvements:

New commands for circular bending, improved finishing attribute assignments, and updates to reverse surface modelling enhance drafting and model preparation. The addition of tangent extension options for split planes and associativity for wireframe annotations further speeds up workflows. - Interoperability Assembly View Improvements

Enhanced element retrieval, consistent naming, and a new Instance Name field ensure accurate assembly representation, reduced file sizes, and greater export flexibility.

2. Plastics and ProgDie Improvements

- Flow Thermal Inserts Visualization:

Designers can now visualize temperature maps for cavity mold blocks, providing detailed insights into the thermal performance of inserts during the molding process. This feature enables better analysis, reduces try outs, and optimizes production quality.

- Multi-Stage Simulation Enhancements:

Refined blank and constraint definitions, updated templates for forming operations, and improved result visualization—now including video and reports—offer a comprehensive simulation experience. These updates allow for faster project completion while predicting and mitigating potential issues. - Part Unfolding Improvements and New Part Study Preparation

Enhanced part and flange recognition, improved etching unfolding, and a new Part Study preparation streamline workflows, reduce manual effort, and expedite project completion. - Standard Components Library

Improved feature creation for cylindrical holes, automatic ejector locking, and updated catalogues simplify operations, reduce manual tasks, and ensure alignment with supplier standards. - Reverse Enhancements

New device integration with the Hexagon family and the addition of the Neutral Axis command provide more accurate data, enhanced scanning methods, and the ability to convert tube or cylindrical meshes into surfaces.

3. Manufacturing Upgrades

- Global Finishing Toolpath:

Achieve superior surface quality with a new toolpath that optimizes the movement of tools across complex 3D surfaces. Designed for precision, it minimizes tool marks, reduces post-machining processes, and ensures parts meet tight dimensional tolerances.

- Clearance Plane Calculations:

A new method for computing clearance planes in 2.5-axis milling and drilling operations enhances safety and flexibility. Automatic stock creation further streamlines operations by reducing manual setup efforts and ensuring rapid movements remain collision-free. - Automatic Stock Creation

New functionality allows stock to be automatically created from pieces when adding operations, reducing manual setup, speeding up model preparation, and further automating the process.

With robust new features and over 150 enhancements, VISI 2024.4 delivers an unparalleled CAD/CAM experience. From design to manufacturing, it simplifies workflows, enhances precision, and empowers innovation.

Upgrade now to take your operations to the next level!