SprutCAM X 17.0.15 cracked release

$ 175.00

Pioneer in Machine-Aware programming

SprutCAM X demonstrates leadership in the field of computer-aided-manufacturing, specifically focusing on CNC programming software. The concept of Machine-Aware Programming was introduced back in 2001. This innovation carefully addresses machines’ and robots’ capabilities and limitations from the very start of the programming phase. This marks a departure from the conventional approach observed in CAM systems, where these considerations are typically integrated during the simulation of machining or the subsequent postprocessing steps.

The outcome is a streamlined process that obviates the requirement for repetitive reprogramming and re-verification cycles, consequently leading to a notable reduction in the timeframe spanning from the commencement of a project to the culmination of the programming code.

Description

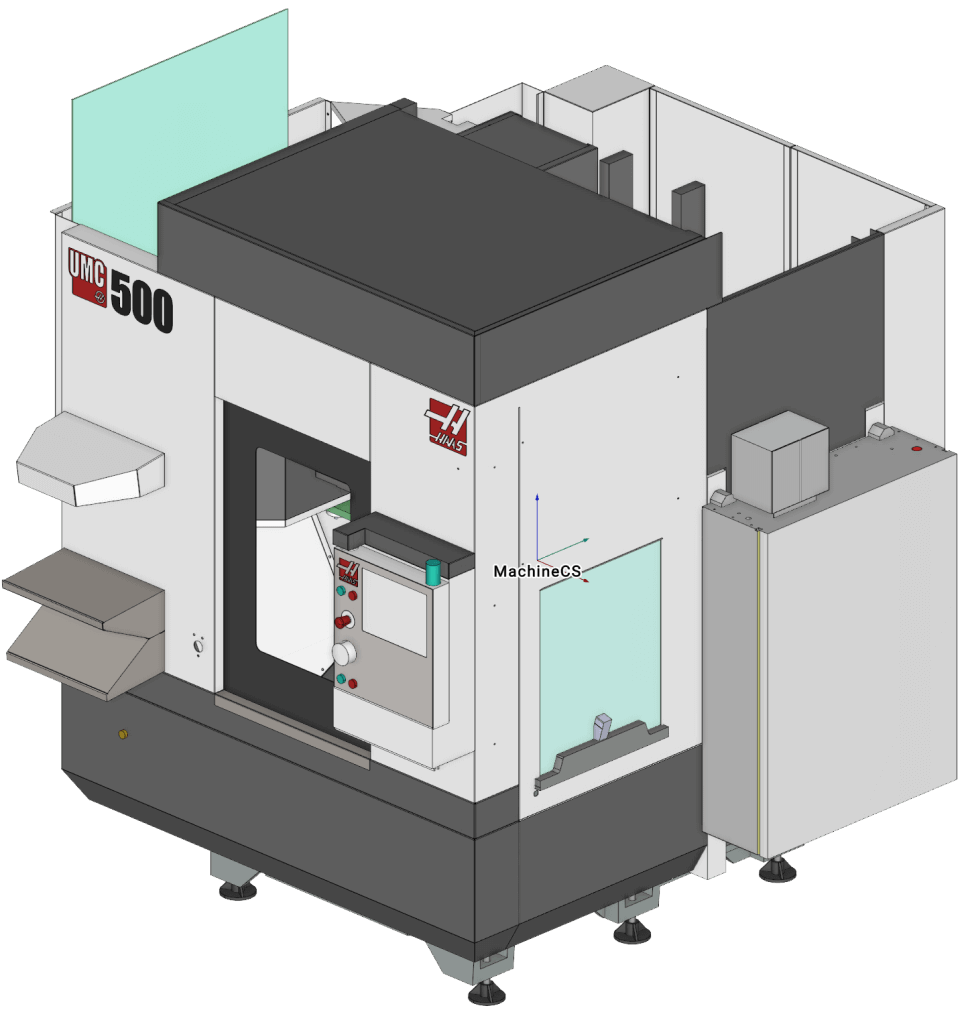

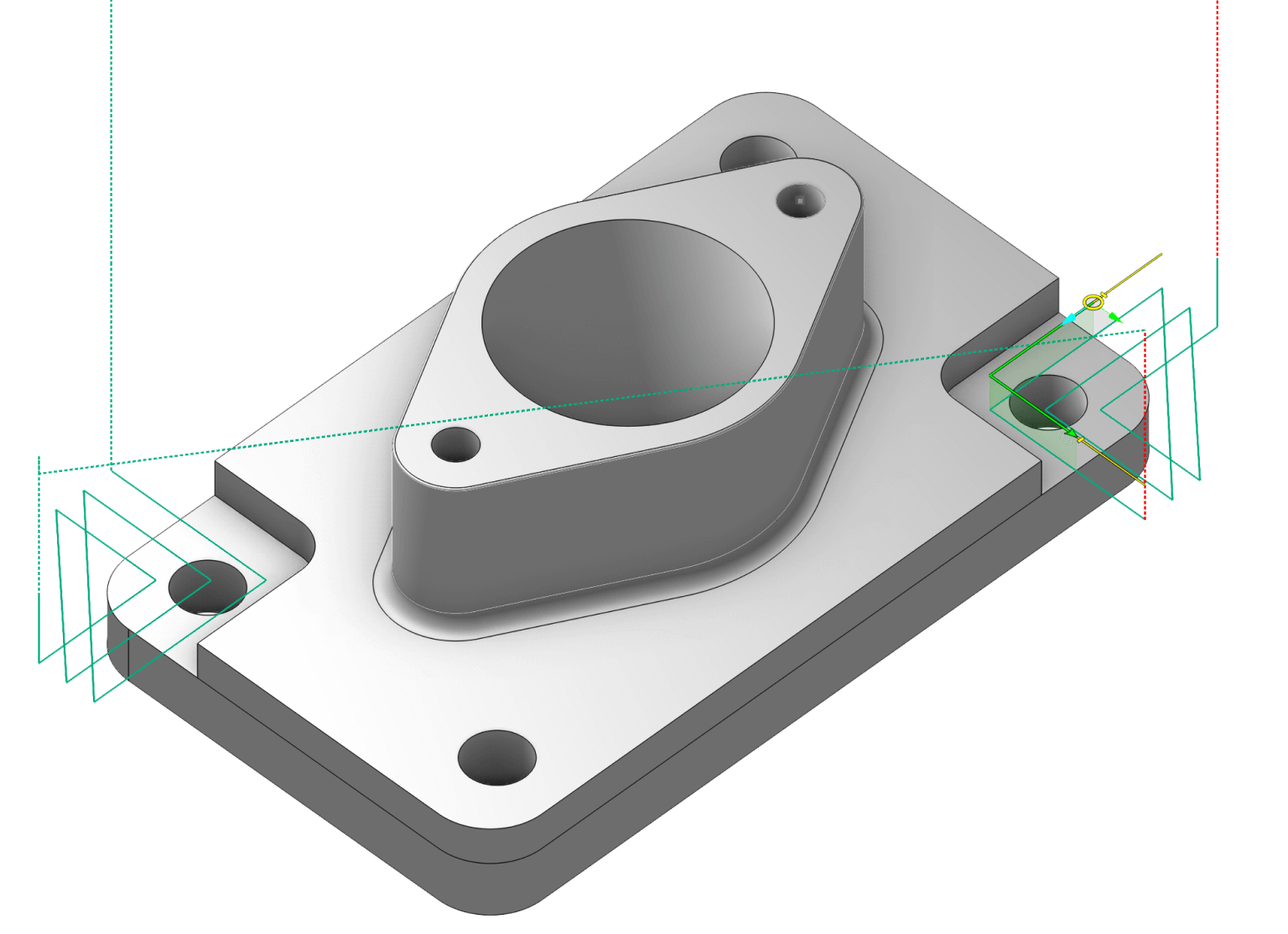

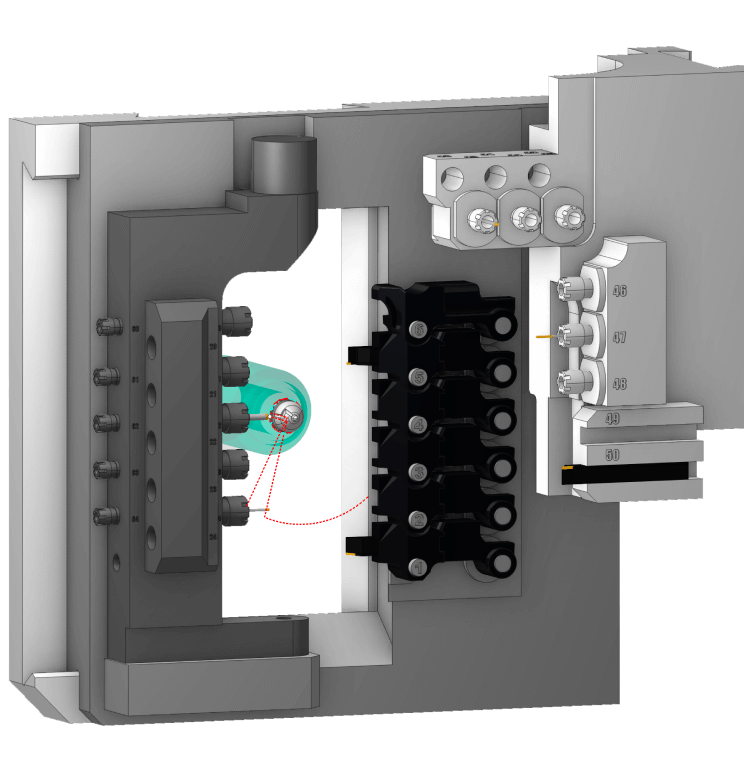

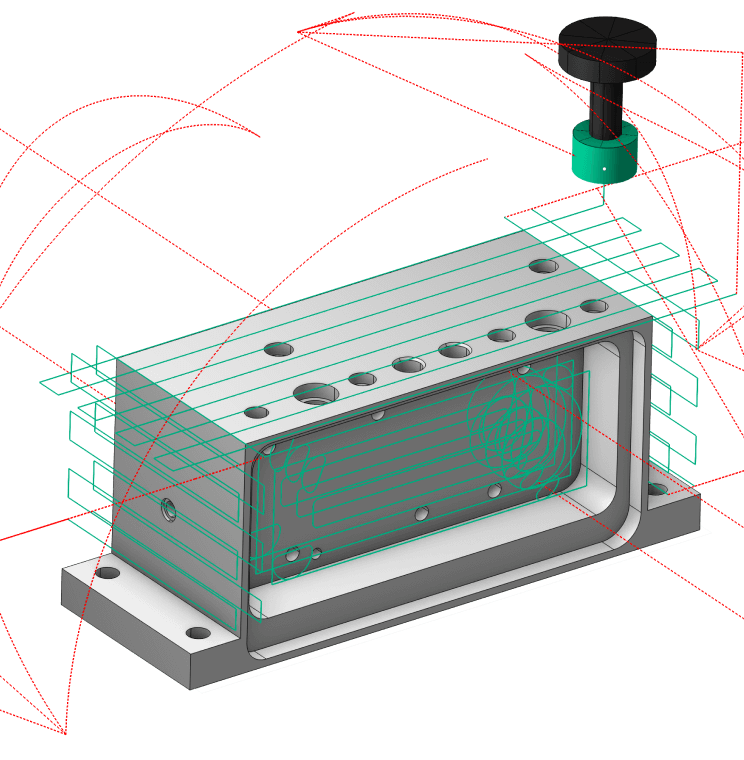

Your CNC Machine digital twin

The MachineMaker app allows you to generate a digital replica of your CNC machine in a matter of minutes. This digital twin is intended for use in programming the CNC machine within the CAD/CAM software SprutCAM X.

Furthermore, MachineMaker features an extensive library of readily available individual components, as well as complete pre-designed digital twins of CNC machines and postprocessors.

Product Highlights

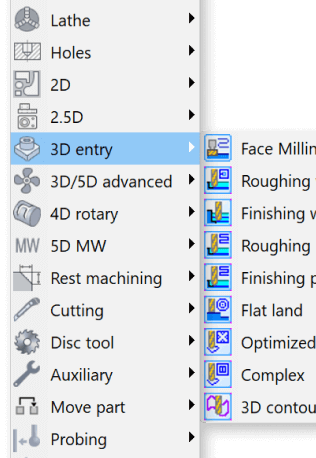

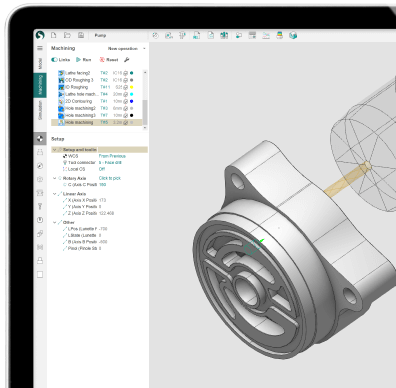

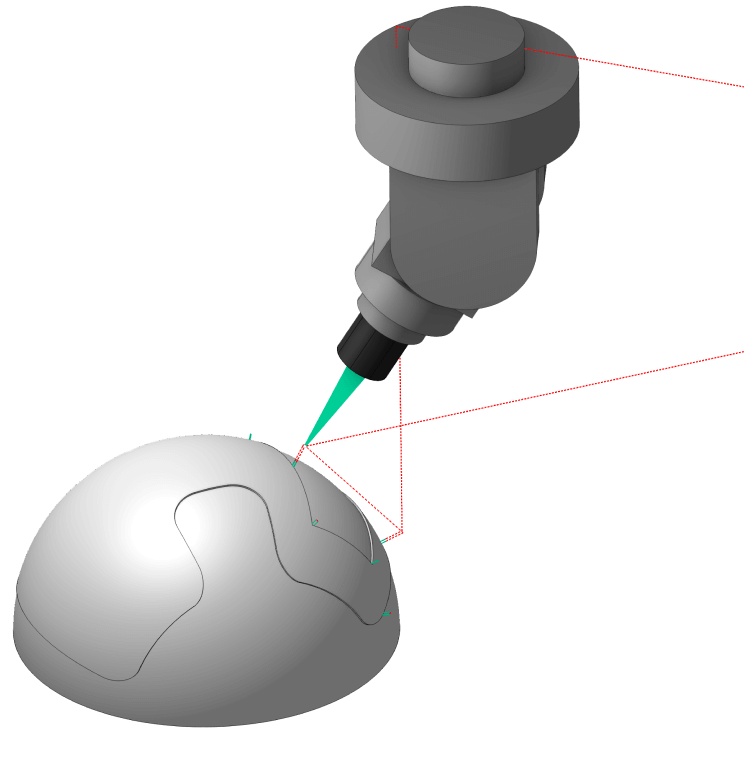

A wide range of machining strategies from 2D to 5D

G-code simulation and transformation to other CNC formats

Interactivity

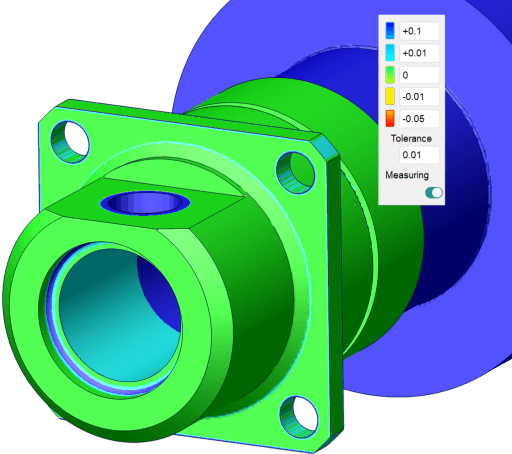

Machining result verification

Parametric CAD

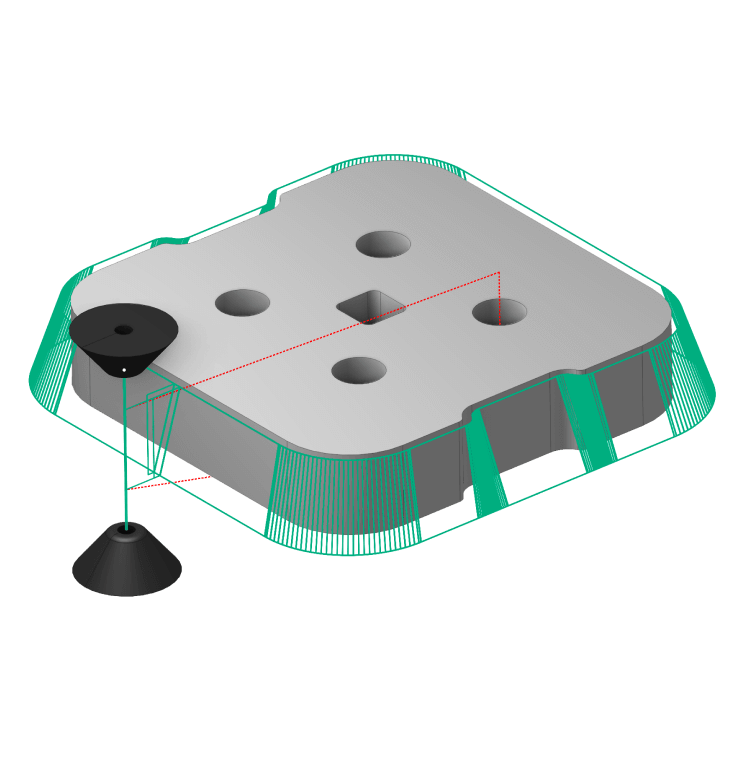

Stock-Aware Toolpath

Collision-free rapid positioning between toolpath cutting cycles

Crisp and clear interface with support of 4K display

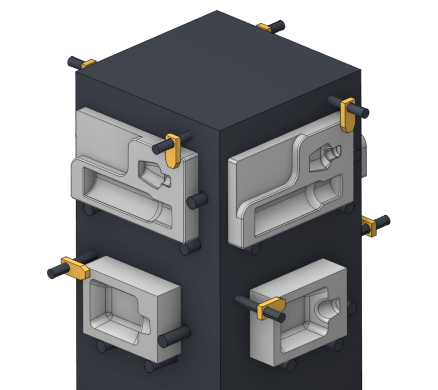

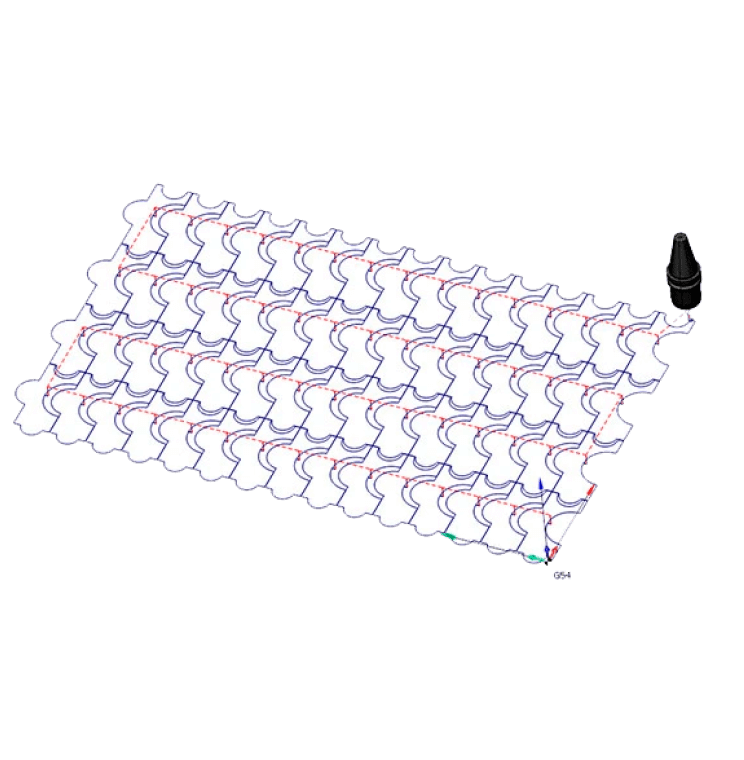

Multi-part projects supported

Snapshots

AI Assistant

Applications

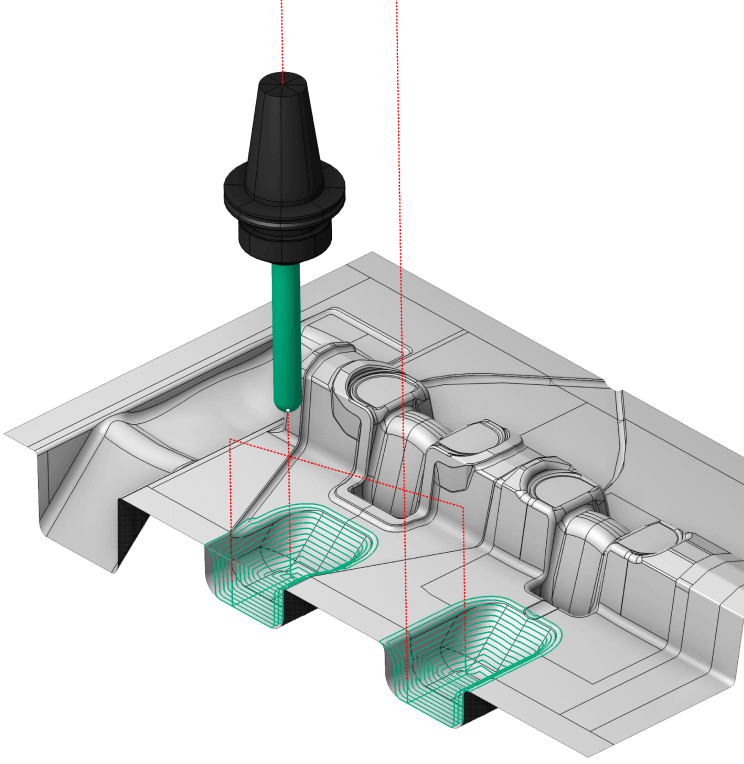

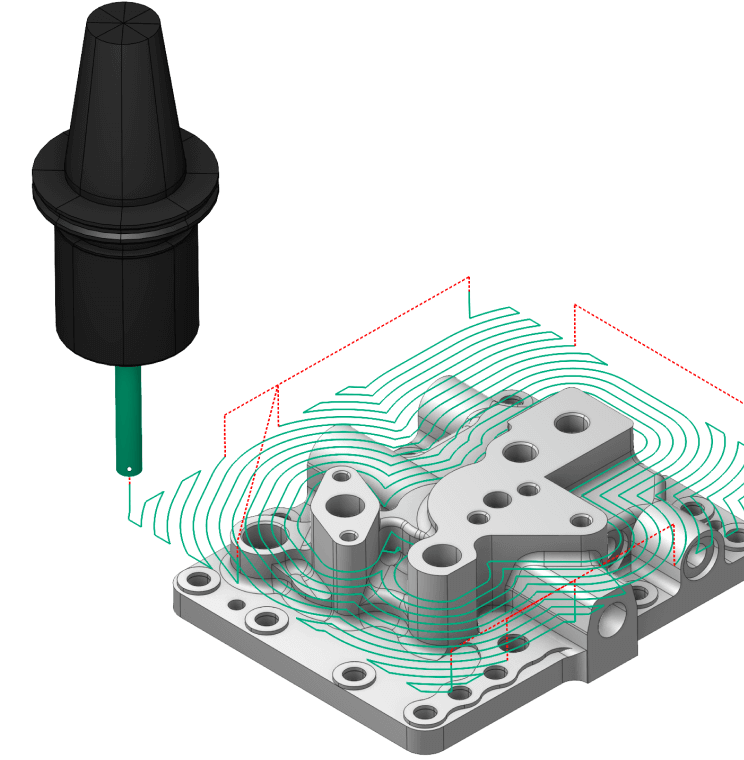

2.5x and 3x mill

Production of molds & dies and other parts on a 3-axis milling machine

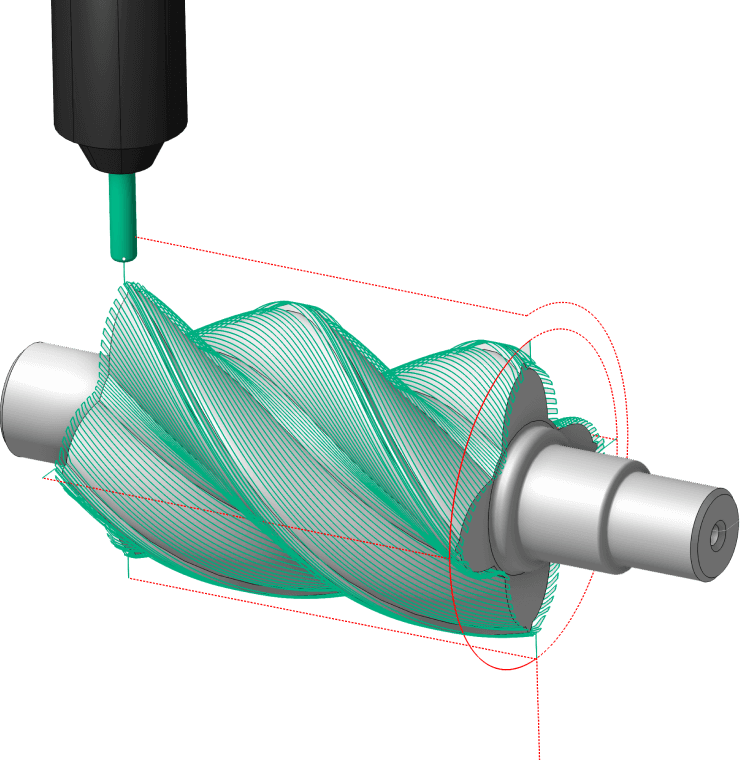

Rotary

Production of screws, blades, gear wheels, balusters

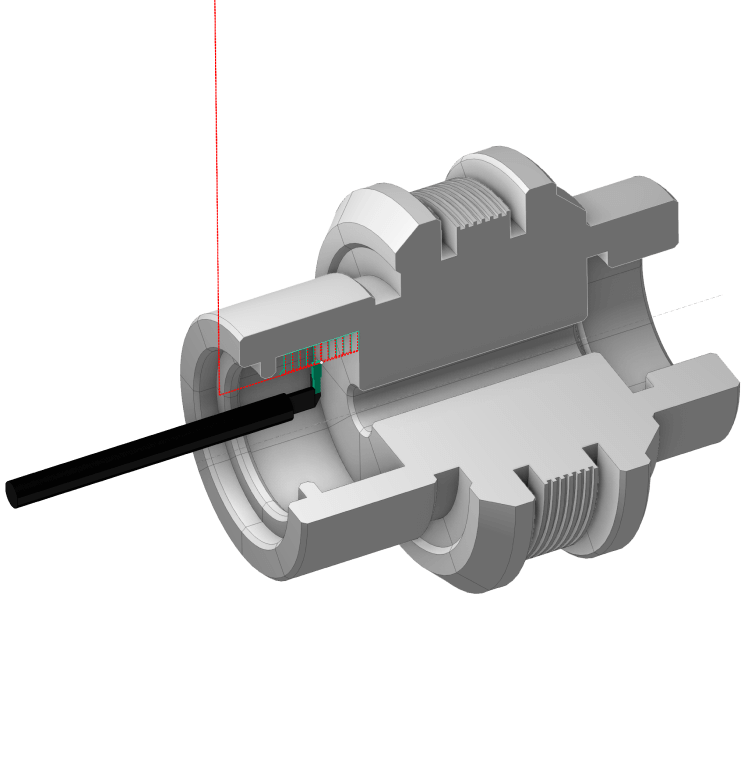

Lathe

Turning and boring, threading, trimming, drilling, reaming

Mill-turn

Turning and milling in one setup

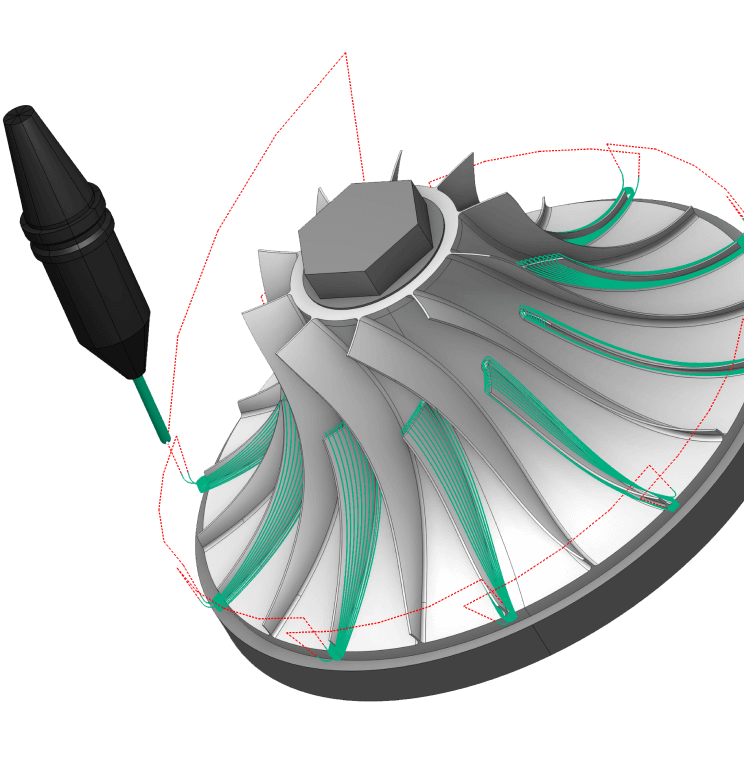

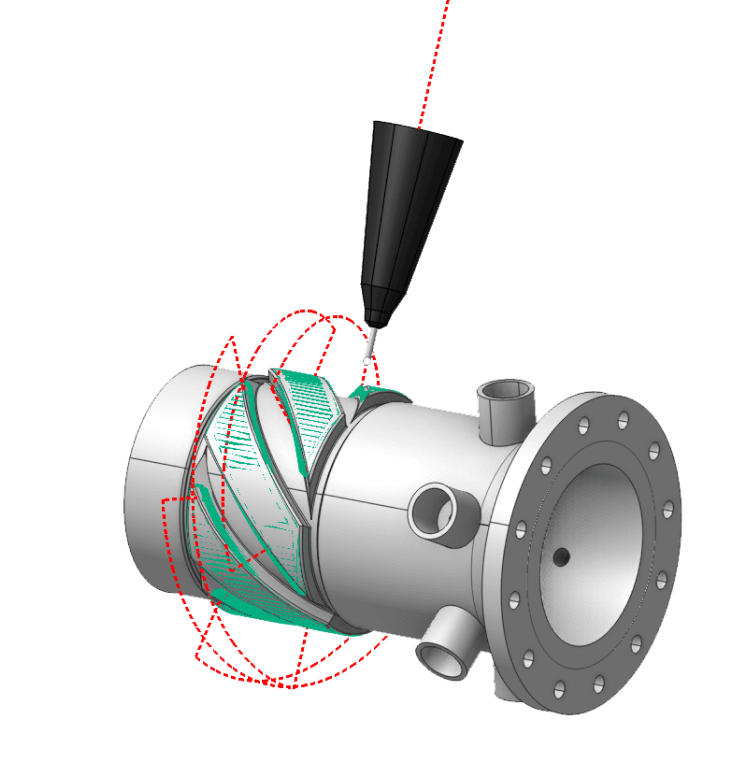

Multiaxis

Index (3+2) and simultaneous 5 axis milling. For turbine wheels, blades, ports

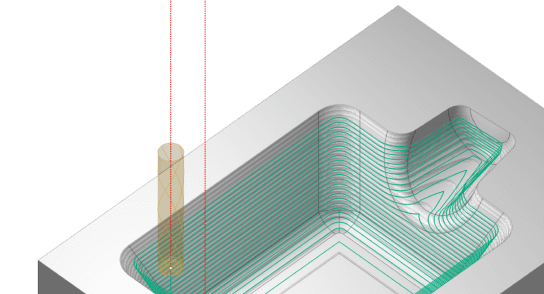

HSM and adaptive

High speed and adaptive toolpaths for quick material removal with extended tool life

Swiss and MTM

Swiss-type machines and MTM (multitasking machining) with synchronization

5-6D cutting

CNC programming of cutting, trimming, 6D knife cutting. Mill, laser, water, plasma, knife

Additive and hybrid

Cladding, hybrid technology on 5-axis, mill-turn machines and robots

EDM

2 – 4 axis strategies for Wire EDM machining

2D cutting

Programming of laser, waterjet, plasma, oxy-fuel cutting and knife cutting

G-code based simulation

G-code verification in SprutCAM

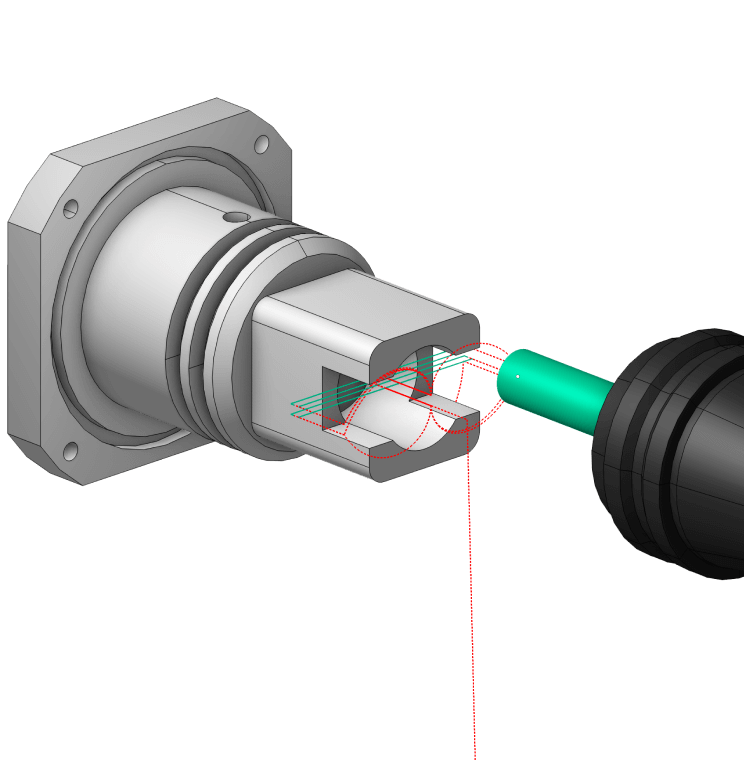

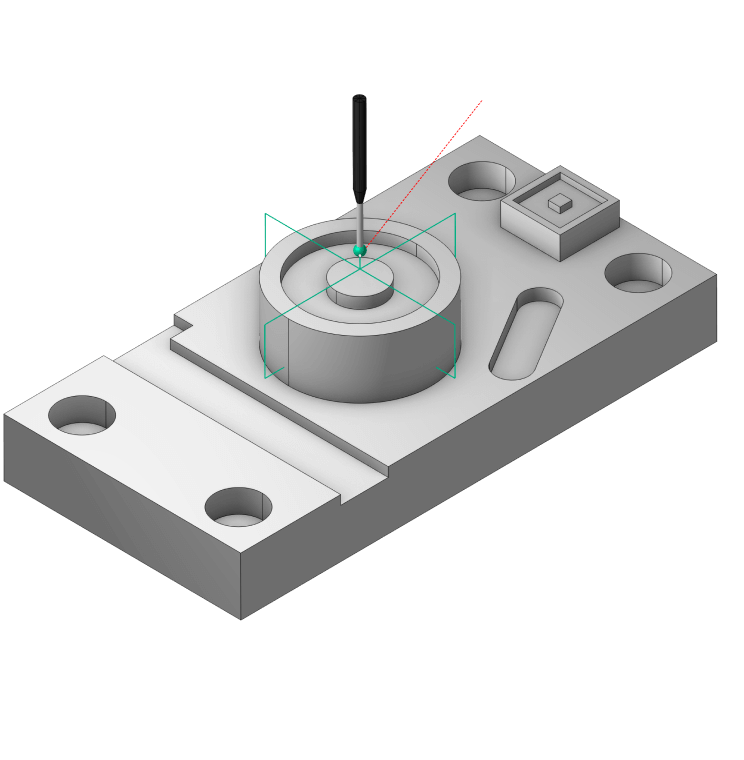

Probing cycles

Probing cycles for Milling and Lathe Machines

Technology highlight:

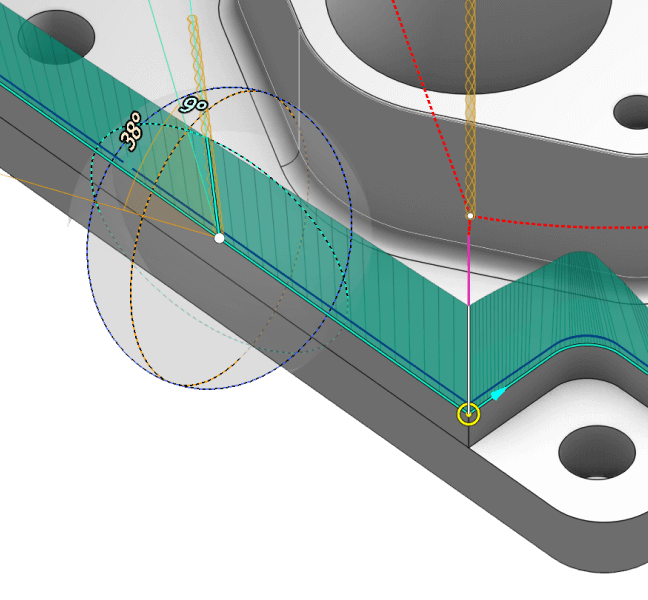

Adaptive SC

This high-speed machining cycle is specifically designed for roughing to substantially decrease cycle times and extend tool life. Its technology automatically regulates chip loads and lateral cutting forces while maintaining the cutter engagement angle and machine axes acceleration within optimal ranges.

With Adaptive SC, the machine can make deeper cuts at higher feedrates, which are also automatically optimized throughout the toolpath for maximum efficiency. In comparison to traditional machining methods, Adaptive SC provides the following benefits:

70%

reduction in cycle time

500%

increase in tool life

SprutCAM X is a widely used CAD/CAM/OLP system for CNC machines and industrial robots. We are pioneers in the field of Machine-Aware programming. This technology considers the movement capabilities and limitations of machines and robots at the initial programming stage, unlike most other systems which integrate these considerations during the machining simulation process. This eliminates the need for reprogramming and re-verification, ultimately reducing the time from project initiation to code completion. SprutCAM X is compatible with any CNC machine: 3/4 and 5-axis Mill, Lathe, Mill-turn, Swiss, MTM, EDM. Toolpath calculation considers full machine kinematics and limitations, including collision avoidance and axis limits control. Enjoy the power, speed, and safety of a natural easy to learn, and use CNC programming workflow. SprutCAM X Robot is an innovative all-in-one CAD/CAM/OLP software that allows you to program complex robot applications without disrupting the manufacturing process and the need for an on-site robot programming expert without purchasing a separate CAM system. SprutCAM X Robot supports various brands and configurations of industrial robots, allowing the user to work in a single interface for programming and simulation and output code for use in actual robotic cell applications. Experience the powerful all-in-one software suite for complex and creative robotics tasks.

What’s new in SprutCAM X 17

General improvements

Interface – new popup dialogs design.

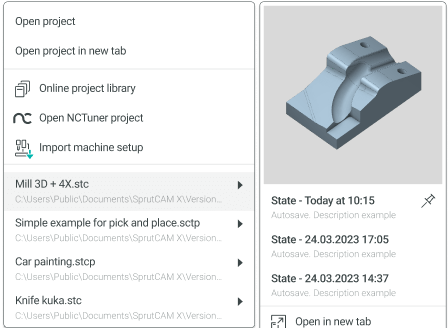

Project Snapshots

Snapshots by events

New project extension – “.stcp”

Machine setup file to create new projects quicker

Project library

Multiproject workflow

Technology updates

Improvements in roughing waterline

Redundant axes optimizer improvements

Added display of periodic rotary axes overturns

Arbitrary machine parameter control using map (optimizer)

Singularity avoidance for the 2-axis rotary table of the robot

Point Pick and Place operation added

Links in basic milling operations improved

Scallop operation toolpath enhanced

New undercut waterline operation added

Undercut tools support in 5D Surfacing operation.

Added slope zone in 5D Surfacing operation

New group of operations added – Spray

Approach/return for the TCPM enabled operations using Local CS

Added new parameter for chip breaking in Roughing lathe cycle

Postprocessing and G-code simulation

.NET postprocessors for G-code simulation

Upgrade to .NET 6.0 version

Tool for creating new interpreters

MachineMaker improvements

CAD enhancements

Design module enhancements

Visual overhaul and better user experience

Full-fledged work with the model history

New 3d modeling operations

New sketching tools

Better stability and performance

New CAD import capabilities

Minor changes

Main application executable file changed

New item ‘Duplicate’ in the context menu of the list of technological operations

Post Processor generator

New Trailing zeros output option in Registers

Search in all commands and subprograms

2D arrays and records

Report generation

New features

Selection items for output in the report

Adding customer parameters for each project tree node

Tuning images for the each project tree node

Helper for pattern creation commands

Output operations by setups