Romax 2022 full cracked license version

$ 150.00

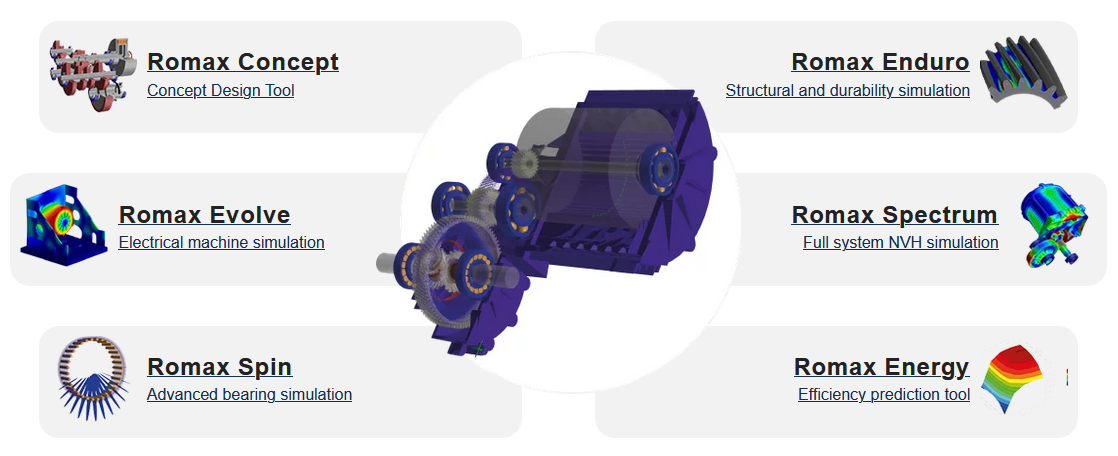

Romax is the trusted industry standard software solution for powertrain durability simulation and optimisation.

Our ecosystem of applications align with your drivetrain and transmission development cycle, from rapid modelling and concept exploration to detailed simulation and virtual product sign-off. Intelligently integrated into the wider CAE world, Romax empowers your teams and enables Right First Time designs. Our software drives innovative powertrain development across industries and supports sustainability initiatives in transportation and power generation.

Description

Usability enhancements

A large portion of the new enhancements relate to usability, as we continue to strive to make our software as easy to use for our customers. These type of improvements are often driven by customer requests and feedback, but also by our expert users at Hexagon, who use Romax software daily, whether for testing and quality purposes or for research or customer projects. Improving the usability of our software not only improves our users’ experience, but can also positively impact the speed and ease of their development cycles.

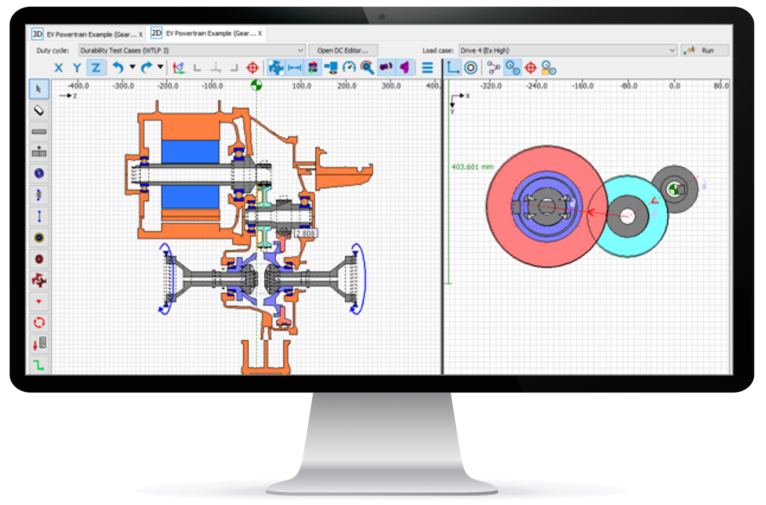

Improvements to 2D modelling

In 2022 we brought Concept’s much-loved 2D modelling interface into Romax DT and Romax Evolve. In 2022.1, we have implemented various improvements to this incredibly user-friendly interface, helping to expedite model creation and editing for our customers. When you can create and edit your models more quickly, you can spend more time doing value-add activities like running the simulations and analysing the results to get the data-driven insights you need for a CAE-led design process.

- 2D sections of FE shafts and casings are now generated in the 2D worksheet. Being able to see and interact with these components, which were not previously supported in this view, makes it much easier to work with complex models.

- Undo and redo functionality has been added to the 2D Worksheet and Shaft Worksheet in Romax DT and Romax Evolve, to make it easier to rectify unintentional changes or to better understand the most recent edits.

- New tools are now available in the 2D Worksheet to merge shafts, cut shafts, add generic parts, and to view the axial direction of all bearing preloads, as well as the ability to model bevel gear sets with multiple meshes. These tools all aim to speed up the modelling process, improve the user experience, and make the model-checking process easier than ever before.

Usability enhancements to bearing results and bearing dynamics

Alongside improvements to usability of modelling, we have implemented usability enhancements in various bearing reports as well as customised reporting, to improve consistency and clarity, ultimately streamlining the process of understanding and interpreting results. Small improvements to our Bearing Dynamics functionality also improve the usability and experience.

Advanced simulation technology

At the heart of Romax software is our advanced simulation technology: from being the first to simulate gearbox NVH in 6 degrees of freedom more than 20 years ago, to more recent developments such as cutting-edge gear root stress analysis, prediction of sideband noise problems in planetary transmissions, and calculation of bearing roller contact and edge stresses within the context of a full system. In 2022.1, we are again making available to our customers some of the latest research and innovation from our in-house team of experts:

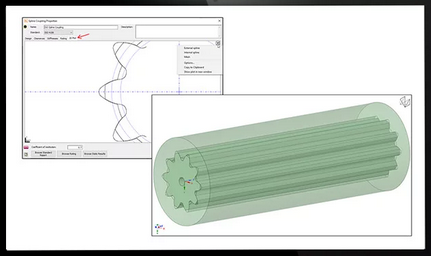

Advanced loaded tooth contact analysis model for cylindrical gears

Loaded tooth contact analysis (LTCA) is an essential tool for designers of geared systems and an integral part of Romax software. Until now, we have used Mindlin plate finite elements to calculate the underlying bending stiffness model – an approach that gives a very good approximation (with accuracy proven through numerous correlation studies), is superior to ISO 6336-based models, and is fast enough to make it ideal for quick calculations and parametric studies. This model has served our customers well for years, and it will continue to do so in the future. However, the model assumes there is no connecting stiffness or influence between any two thin sections of the tooth and no tooth-to-tooth interaction. While these assumptions are acceptable for most common use cases, some situations require more advanced analysis to confirm final design performance.

In 2022.1, we have developed a more advanced bending stiffness model using a 3D finite element approach – this inherently captures edge effects, elastic coupling between different parts of a tooth and between neighbouring teeth. It is therefore able to capture behaviours such as Poisson’s effect.

Bearing load and stress calculations now consider ball contact ellipse truncation

In ball bearings under certain operating conditions, especially large axial force combined with bending moment, the contact area between the elements and the raceways may go outside the edge of the raceway, which is referred to as truncated contact. Romax 2022.1 enhances the previous truncation prediction capabilities to consider the increased stresses in the truncated contact ellipsis and the effect of truncation on ball load distribution, making the bearing load distribution and contact stress results for ball bearings more accurate than before when the contact ellipse is truncated.

ISO/TS 6336-4:2019 tooth fracture fatigue of cylindrical gears

In addition to gear failure modes characterised by scuffing of the flank surface or cracks initiated at the surface (such as pitting and tooth breakage), it is possible for cracks to initiate below the surface close to the core-case boundary. These cracks result in tooth breakage known as tooth flank fracture (TFF) or tooth interior fatigue fracture (TIFF). 2022.1 features the implementation into Romax Enduro of Method A from the ISO/TS 6336-4:2019 standard, which describes a procedure for this calculation. This is of particular interest to the wind industry, or any user with large tooth, high cycle gear applications.

ePowertrain developments

eNVH force import from Manatee by EOMYS

Continuing our strategy of working with industry-leading electromagnetic partners, we have added an interface between Romax software and Manatee by EOMYS. This partnership enables customers to import excitation data from Manatee into Romax Spectrum or Romax Evolve, to then perform NVH analysis on their electromechanical system. By combining the electric motor sound power with that of the gears, users can gain a more holistic understanding of the system behaviour. The workflow does not require manual processing to make the data compatible, and multiple torque levels are handled simultaneously, with a simple interface for selecting operating points.

Edit material properties in FE model

A new option has been added to allow users to edit the isotropic and orthotropic material properties of FE materials. This allows the user to check the sensitivity of their design to changes in the material of the electric machine stator without having to manually edit the FE data in separate software and then re-import it multiple times. Considering these material changes reflects the variation that will inevitably occur during production and helps the designer to ensure the design stays within the desired NVH performance limits.

Collaboration and integration

Support for REXS version 1.4

We have upgraded the version of REXS used in Romax software to version 1.4 and added support for detailed cylindrical gear macro- and micro-geometry parameters and external loads to the REXS import and export in Romax Enduro, Spectrum, Spin and Energy. This improves the interoperability of Romax software with other software that supports the REXS format.

Particleworks

The original release of the Particleworks CFD interface only supported export to Particleworks v7.0.0. Now, the interface supports Particleworks v7.1.0 and later, including the current latest release v7.2.1.

Parametric study and batch improvements

Several enhancements to Parametric Study and Batch Running are included in version 2022.1. These include additional bearing and gear results, generating profile shift coefficient of gears when not using a design tool, and some new gear plots that can be generated using actions. These enhancements give more flexibility to what can be achieved in an automated way using Parametric Study and Batch Running.

Generative Design employs computational algorithms along with artificial intelligence and machine learning to mimic nature’s evolutionary processes. It offers new high-performance design iterations that optimise a product’s mechanical performance. Engineers can also explore design possibilities according to part constraints and requirements to deliver a first-time-right additive manufacturing solution.

- Bearing Dynamics Desktop Application and Support for Cylindrical Roller Bearings: our Bearing Dynamics capability is now available as a desktop application, for analysis of failure modes not considered by the standard methods, with an updated UI and support for new bearing types.

- 2D Gearbox Modelling Worksheet: a new system-level worksheet with drag-and-drop tools, allowing intuitive, fast modelling which is easy-to-use, even for beginners and non-experts.

- Parametric Study and Batch Running Improvements: new actions, targets and results available for gears, bearings and to allow genetic algorithms to be used for full gearbox optimisations. This includes comprehensive targets and results of raw and actual values of viscosity ratio and contamination factor, useful for detailed analysis of the influence of lubricant additives in different load cases in an automated way.

- Reporting of bearing passing frequencies and orders: The passing frequencies found in rolling bearings are commonly used to identify the source of defects. Rolling bearing passing frequencies and orders are now reported in the Bearing Results worksheet.

- JMAG-Express Online Integration: JMAG-Express Online can now be opened from within the Romax environment, so users can generate an electric machine design and import the machine geometry directly into the Romax model as part of an early-stage structural analysis.

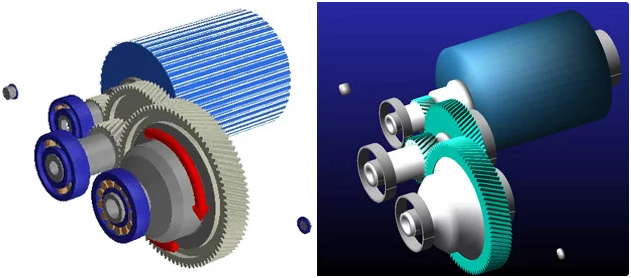

Bearing Design

Advanced, integrated analysis of rolling element bearings to give unrivalled insight into bearing performance.

- Fast parametric modelling of the system and the bearing internal geometry for easy design space exploration

- Flexible model fidelity from single bearing to complex systems with flexible bearing rings and other structures

- Enhanced bearing contact analysis featuring a coupled strip model accurately capturing roller edge stresses, end effects, material yield, rib contact, and truncation

- Time domain bearing skidding analysis capability

Application Optimisation

Easily and quickly build a parametric model of any electro-mechanical system and perform bearing selection and application optimisation with confidence.

- Accurately model the loading, mounting and thermal conditions and evaluate system loads, deflections, misalignments

- Quickly and accurately predict element and raceway load and stress distribution, rib contact, edge stress, and contact truncation

- Evaluate optimum preload/clearance settings and how they are affected by thermal and structural conditions

- Perform ISO 281 and ISO/TS 16281 ratings, augmented by the enhanced bearing contact model

- Import and export CAD geometry, mesh and connect finite element components and produce graphics and reports

Better collaboration

Romax Spin works seamlessly across the Romax product family and integrates into your process.

- Exchange models with your suppliers and customers in various formats including REXS

- Create, share, and use proprietary bearing databases protecting the IP of the creator

- Access the same shared bearing database within your organisation

- Automate analysis tasks and integrate them with third party applications through the Batch Running capability

- Obtain results directly from SKF’s cloud calculation service without leaving Romax Spin