Cast-Designer V7.8 cracked release

$ 200.00

C3P Software, a pioneer supplier of CAX & PLM solution for industrial manufacturing processes, announced today the launch of the latest version of its design, simulation, and optimization solution for casting industries – Cast-Designer V7.8

A practical cast designer and simulation software that enables the investigation of the cast parameters and eliminates the possible failures of the casting process during the design phase. It’s a reliable tool for product and casting tool designers for cost- and time-effective cast design and production. The core of the “upfront design & analysis technology” is to allow engineers to conduct fluid flow, heat transfer, and solidification analysis with the assistance of a combination of expert systems and CAE technology.

Description

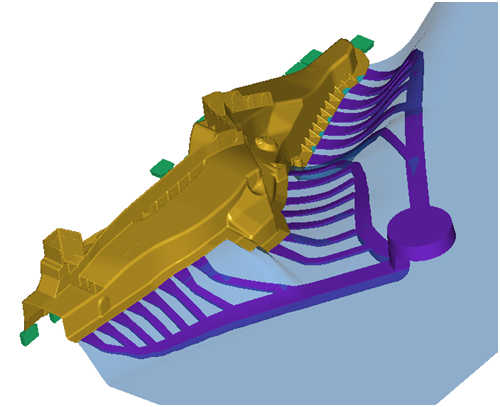

Smart Runner

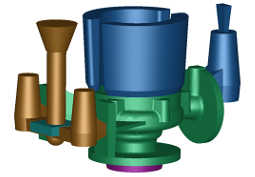

A properly designed gating system ensures uniform filling of molten metal into the mold cavity, minimizes turbulence and air entrapment, reduces porosity and shrinkage, and achieves optimal solidification control. The Cast-Designer software by C3P Software allows users to create, analyze, optimize, and visualize gating systems based on their specific geometries and requirements and simulate the entire die casting process including filling, solidification, and cooling.

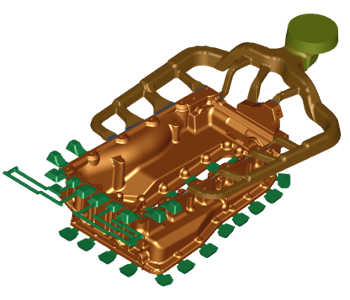

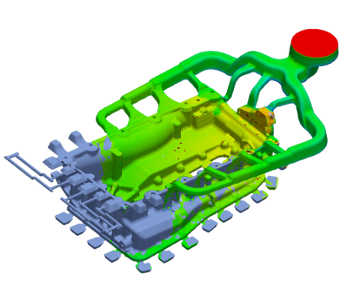

In Cast-Designer V7.8, C3P software has recently introduced a new function called “Smart Runner” to its package, which can automatically generate runner systems for even the most complex gating system designs. The Smart Runner function utilizes advanced algorithms and machine learning technology to analyze the gating system geometry and generate optimal runner designs based on user-defined criteria such as pressure drop, flow rate, and cavity balance. This automated approach ensures greater accuracy, consistency, and reliability in the gating system design process while saving engineers time and effort. This innovative feature speeds up the process by 20 times compared to manual design and provides superior results for die casting engineers.

Advanced 3D Runner Generation

In addition to its automated runner design capabilities, Cast-Designer V7.8 can also generate complete 3D gating systems more efficiently and accurately than traditional methods.

The user can create a gating system in a plan working space at first, then, the software generates a CAD projection from the plan mode onto the 3D die cavity, resulting in a fully realized and optimized gating system. This approach is ten times faster than traditional methods that rely on manual measurements and calculations to create 3D gating systems.

The greater efficiency and accuracy provided by the Smart Runner function enable designers to produce more complex gating system designs with ease, save time and effort, and optimize the performance of the final product.

“Thanks to the Smart Runner function, designers can explore multiple design options quickly and efficiently, fine-tune the runner system to achieve optimal performance, and avoid costly mistakes and rework. The generated runner designs are easy to modify and integrate with other components of the gating system, providing flexibility and versatility in the design process. Prof J. Zhang from Tsinghua University summarized.

“The Smart Runner function in Cast-Designer software has proven to be extremely effective at designing gating systems, even for complex applications such as Giga casting. For example, the runner system for a Giga casting may involve more than 20 or even 30 sub-runners in a fully 3D runner system.” David Keck, marketing director of C3P Software declared, “In many cases, designing such a complex runner system would take considerable time and effort using traditional methods. However, with the Smart Runner function, the same task can often be completed in less than 10 minutes, with greater accuracy and consistency than manual measurements and calculations would provide.”

About C3P Software

C3P Software has been providing the professional design & analysis solution for the manufacturing industry since 2006, and the current product “Cast-Designer“,”Cast-Designer Weld“, “Geo-Designer“, “AI-FORM“, “SavingCAST“, “C3P Engineering Tools” and “CastWorks” are marketed worldwide. With the combination of software development, advanced analysis, extensive product development experience and cost-effective human resources, C3P Software provide industry and manufacturing business with comprehensive solutions and engineering services on a global basis to meet their expectation in high quality, on-schedule delivery within cost target. Our business scope covers software development, professional engineering service and application software integration.

CAST-DESIGNER OVERVIEW

C3P Engineering Software International Co., LTD has developed a software namely Cast-Designer, which is specially designed for Casting business. The Cast-Designer software has more than 50 years of industry experience to provide end-to-end solution for foundry industry, ranging from metal charging, DFM analysis, step-by-step guidance in gating system design, advanced thermal, flow, solidification and stress simulations and artificial intelligent based automatic optimization.

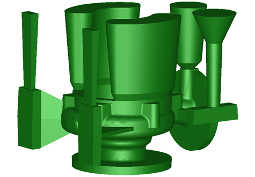

3D Casting part

Gating system design

Process analysis & optimization

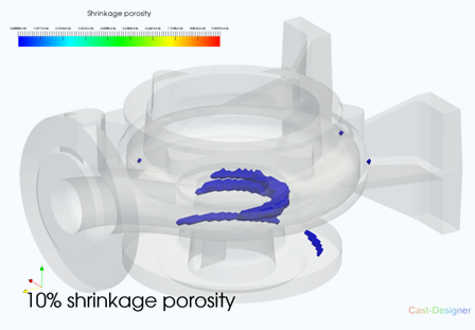

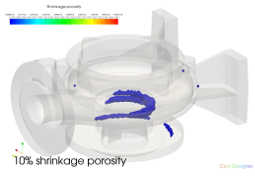

The Cast-Designer software supports all major foundry processes and predicts the casting defects like shrinkage porosity, air entrainments, surface defects, residual stresses, distortions etc. The Software Helps foundry engineers to make right decisions early in the design stage of casting system development and to improve quality & yield ultimately reduce the manufacturing cost. It can also help the industry to achieve the target of ‘Time to Market’, ‘Quality to Market’ and remain ‘Competitive’.

3D Casting part

Gating system design

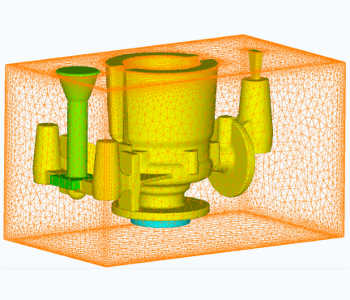

CAE Modeling

The Cast-Designer software is a quick casting design and analysis tool which is based on Upfront Design and Analysis Technology. The core of Upfront Design and Analysis Technology is to allow engineers to conduct fluid flow, heat transfer and solidification analysis with the assistance of combination of expert system and CAE technology. So that it helps engineers to make a Right decision in the early design stage of a project. The Upfront design & analysis technology have already been becoming a very important role in main stream design process.

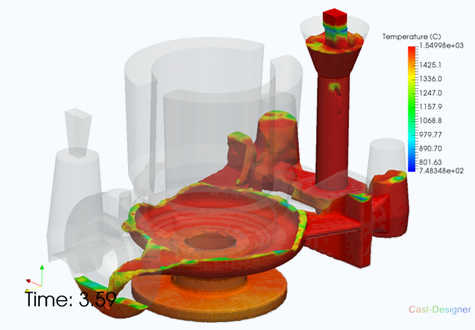

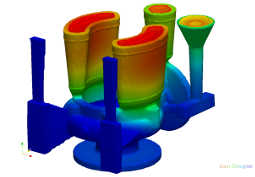

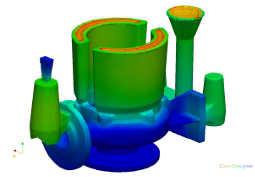

Flow simulation

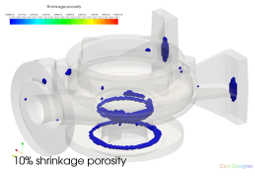

Shrinkage porosity

DESIGN PLAN EVALUATION

The Cast-Designer provides a powerful tool to evaluate different design plans in fast and easy way.

For example, the existed casting part was steel with 23.5Kg, two design plans were studied.

PLAN-A

With 27.2Kg riser and the solidification time was 853 sec, the final shrinkage porosity volume was 20.51 cm^3.

PLAN-A

Flow result (A)

Solidification result (A)

Shrinkage porosity (A)

PLAN-B

With 26.2Kg riser and the solidification time was 404 sec only, the final shrinkage porosity volume was 4.17 cm^3.

PLAN-B

Flow result (B)

Solidification result (B)

Shrinkage porosity (B)

So, with the Cast-Designer Software, the users can optimize a casting design by detecting the part features with potential flow and solidification problems as well as evaluating difference casting systems in the early design stage. Even a novel with limited experience in simulation who can easier to undertake the design, setup in a very short period of time.

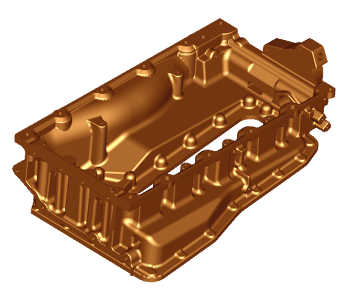

Casting

Die Casting

CAST-DESIGNER for Die Casting is an expert package specifically designed for high-pressure die casting with advanced gating system design and fast validation capability.

Cast-Designer is a quick casting design and analysis tool based on upfront design & analysis technology. The core of the “upfront design & analysis technology” is to allow engineers to conduct fluid flow, heat transfer, and solidification analysis with the assistance of a combination of expert systems and CAE technology. It helps engineers make the right engineering decisions in the early design stage of a project. Upfront design & analysis technology has already been becoming a very important role in the mainstream design process.

Gravity Casting

CAST-DESIGNER for Gravity Casting can make the casting system design and fast simulation for sand casting, gravity die casting, low-pressure die casting, investment casting, lost foam casting, centrifugal casting, etc.

The Casting system of Gravity Casting could be done in Cast-Designer with KBE support. The ‘Smart riser’, ‘Smart chill’, and ‘Free design’ provide full functions for the gravity casting system in the last AI technology.

- Focus on riser design, to avoid shrinkage porosity and keep thermal balance as well as material saving.

- Special ‘EMDI’ technology to define the best riser location.

- ‘Smart riser’ to design riser size automatically.

- Support riser database and customer database.

- Same approach for chill design. Special technology to generate complex conformal chills can save 90% CAD time.

- Riser design at first, then chill, then gating system.

- A free design approach for a gating system supports any complex gating and runner.

- Cooling system design also.

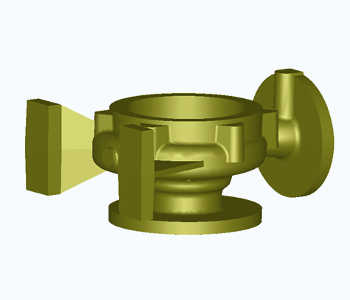

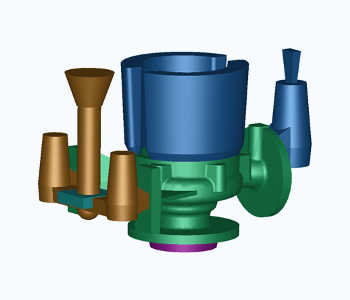

Investment Casting

Cast-Designer for investment casting is a quick casting design and analysis tool based on upfront design & analysis technology.

The designer module can help the gate and man tree design to avoid the shrinkage porosity on the heavy region. The ‘smart gating system’ provides a main tree library with a built-in knowledge base to optimize the solidification process. The CPI simulation offers a very accurate method for design validation.

Welding

Cast-Designer Weld

The unique solution for complex large welding and assembly process, with full chain solution from the material →to process design →to simulation →to production and automatic optimization from welding parameters and assembly sequence.

Cast-Designer WELD is practice-oriented, fast, and easy to use. The user can focus on the engineering-related details of the welding process instead of dealing with the software operation.

Welding Calculator

The weldability (also known as the joinability) of a material refers to its ability to weld. Many metals and thermoplastics can be welded, but some weld more easily than others. A material’s weldability is used to determine the welding process and to compare the final weld quality with other materials.

A built-in calculator can help users to calculate many useful results, which can be used for weldability analysis.

The Welding Calculator supports the planning and optimization of welding tasks such as the calculation of weldability, cooling time, preheating temperature, and the required filler metal quantities.

Stamping

AI-FORM

AI-FORM is the first AI-based interactive multi-objective optimization commercial software in the market today directly applied to sheet metal forming. The software is specially designed for the sheet metal forming business and having more than 20 years of industry experience, provides an end-to-end solution for the stamping industry, ranging from 3D part DFM analysis, quotation, blank sheet engineering, step-by-step guidance in die face design, KBE, advanced FEM simulations and AI-based automatic optimization.

With the development of industrial, stamping products and production process becomes more and more complex. At the same time, CAD and CAE technology are also widely used in all industrial segments. The rapid development of computer systems in hardware and software greatly reduces the simulation time, such as parallel computing technology. Therefore, seeking the best solution and improving design has become the next hot topic.

With the geometrically driven technology, multiple design alternatives can be automatically evaluated, which significantly shortens the product design cycle and significantly improves product quality and reliability.