CADmeister 2024 cracked full release

$ 170.00

CADmeister2024: Revolutionizing Design and Manufacturing with Advanced 3D Data Utilization

CADmeister2024 is a cutting-edge CAD software solution designed to enhance productivity and efficiency in design and manufacturing processes. With its advanced capabilities for leveraging 3D data, CADmeister2024 promotes consistent performance and seamless workflow integration…

Description

This powerful tool simplifies initial processes and improves information flow by enabling the reuse of existing 3D data, ensuring accuracy and reducing redundancy. CADmeister2024 creates a user-friendly environment that empowers customers to maximize the potential of their 3D data, driving innovation and efficiency.

By embracing digitalization and optimization, CADmeister2024 supports the entire design-to-manufacturing lifecycle. It streamlines workflows, enhances collaboration, and ensures that every step—from concept to production—is optimized for success.

Key Benefits of CADmeister2024:

- Advanced 3D Data Utilization: Harness the full potential of 3D data to improve design accuracy and efficiency.

- Streamlined Processes: Simplify initial workflows and enhance information transfer by reusing existing 3D data.

- User-Centric Environment: Enjoy a seamless and intuitive platform designed to maximize productivity and ease of use.

- Digital Transformation: Drive innovation by integrating digitalization and optimization into every stage of design and manufacturing.

Upgrade to CADmeister2024 and experience a smarter, faster, and more efficient way to manage your design and manufacturing processes. With its advanced features and focus on 3D data utilization, CADmeister2024 is the ultimate tool for businesses looking to stay ahead in a competitive market.

Enabling concepts to take shape and out-of-the-box creation

Modern-day artisanal masters create new forms that transcend common sense and limitations.

We believe that supporting their uncompromising persistence is a mission of CAD/CAM systems of the future.

We will continue to challenge ourselves to develop further innovative technologies as the optimal partner for prominent contemporary artisans, tenaciously devoted to manufacturing, through CADmeister which enables them to conceptualize images that could otherwise never be discovered through an evolutionary approach.

PRESS DIE

PRESS (Support for designing press dies)

The module supports designing press dies. It consists of three key function items: design support, modeling support, and post-process support.

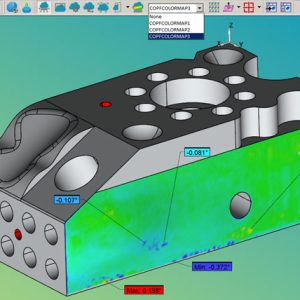

3DModel-Checker automatically checks design data by three-dimensionally positioning drawing check data (that indicates how drawings should be) to overlap design data and compare, to the extent that data measurement and specifications accept objective verification. 3DModel-Checker reduces workloads by automatically verifying parts as well as part constituents of design data by comparing with those of drawing check data.

CAE-PRESS (Support for stress analysis)

This module is for a stress analysis which enables seamless operations between CAD and CAE for designers. Designers can perform stress analyses through simple input CAD operation without being concerned with CAE.

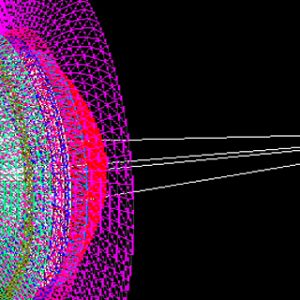

PRESS-SIM (Support for easily creating Trim (Flang) Geometric Nets and Blank Geometric Nets)

This is a simple simulation capability for shaping a press die. This enables a quick understanding of ‘Blank Deployment Lines’ and ‘Flange Deployment Lines (Trim Deployment Lines)’ that will help quotations at the initial stage of designing.

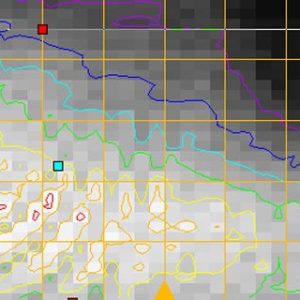

DL enables three-dimensional supports. It is used for the design stage for improving quality of DL design

FORM-EX (Support for modeling and forming)

This enables quick and precise modeling in order to help users shorten the delivery time.

It can form and model by taking into consideration the characteristics of press die forming, empty-weight deflection (that is needed for confirming interference against die parts when transferring panels), material characteristics, and STL figures.

PRESS-FORM-PLUS-II enables direct references to the results of simulation analyses of sheet metal forming (in the form of NASTRAN format file) in order to improve the preciseness of forming at the initial stage.

DRAW-DIE-EX can shorten a designing phase through the use of Dynamic Navigator, navigation tool, regardless of the skills of individual users.