ESI BM-STAMP 2025

$ 160.00

BM-STAMP 2025 – Advanced Sheet Metal Stamping Simulation Software

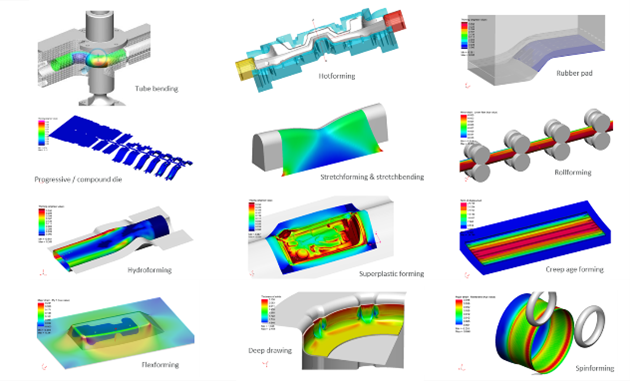

Optimize automotive body manufacturing with ESI BM-STAMP 2025, the latest stamping simulation software for engineers. Predict cracks, wrinkles, and springback with high accuracy, improve surface quality, and reduce costly tryouts. Designed for ease of use, BM-STAMP 2025 delivers fast, reliable results for sheet metal forming, die design, and press line optimization. Ideal for automotive OEMs, suppliers, and manufacturing professionals seeking cutting-edge stamping simulation technology…

Categories: CAD, CAE.CFD

Tags: automotive body manufacturing, automotive stamping, BM-STAMP 2025, BM-STAMP software, die design software, ESI stamping simulation, high-strength steel simulation, metal forming simulation, sheet metal forming, springback simulation, stamping CAE software, stamping simulation software, surface quality prediction, virtual tryout software

Description

ESI BM-STAMP 2025 – Advanced Automotive Stamping Simulation Software

BM-STAMP 2025 is the latest version of ESI’s stamping simulation software designed for automotive sheet metal forming and body manufacturing. Built on decades of expertise in virtual manufacturing, the 2025 release offers new functions, performance improvements, and bug fixes that make it the most reliable and efficient solution for stamping engineers, die designers, and manufacturing teams.

With BM-STAMP 2025, companies can reduce costly physical tryouts, detect formability risks earlier, and optimize press line operations with greater accuracy. This release empowers OEMs and suppliers to deliver lighter, stronger, and defect-free components while saving time and costs.

🔹 What’s New in BM-STAMP 2025

The 2025 version introduces several cutting-edge functions that help engineers tackle the challenges of modern stamping processes:

-

Enhanced Defect Prediction: Improved solvers for predicting cracks, wrinkles, thinning, and localized failures during sheet metal forming.

-

Virtual Light Room Technology: A powerful tool for evaluating Class-A surface quality, detecting cosmetic defects such as waviness or orange peel before physical prototypes.

-

Springback Compensation Tools: Multi-stage compensation workflows that ensure stamped parts achieve dimensional accuracy after forming.

-

Tool & Press Elasticity Modeling: More realistic simulations that account for die and press deformation, especially important for large automotive panels and high-strength steels.

-

Material Utilization Optimization: Smarter algorithms for blank outline design, reducing material waste and cutting production costs.

-

Improved CAD Interoperability: Seamless import/export of models from CATIA, NX, Creo, and other PLM systems.

🔹 Highlights & Key Benefits

BM-STAMP 2025 delivers more than just technical improvements — it’s engineered for practical usability and business impact:

-

🚀 Fast Ramp-Up – Intuitive workflows allow engineers to learn the software in hours and achieve full productivity in days.

-

⚙️ Scalable High-Performance Computing – Parallelized solvers optimized for multi-core CPUs and cluster environments.

-

💡 Predictive Accuracy – Reliable results across a wide range of materials including high-strength steels, aluminum, and advanced lightweight alloys.

-

💳 Token-Based Licensing – Flexible licensing shared across ESI’s virtual manufacturing ecosystem.

-

💼 Industry-Ready – Designed specifically for the automotive stamping industry, validated by OEMs and Tier 1 suppliers worldwide.

-

⏱ Reduced Development Time – Early defect prediction and virtual validation shorten time-to-market.

-

💰 Cost Reduction – Minimize tryouts, reworks, and wasted materials, lowering overall production costs.

🔹 System Requirements for ESI BM-STAMP 2025

To ensure smooth operation, the following system configuration is recommended:

-

Operating System: Windows 10/11 (64-bit), Red Hat Enterprise Linux, or SUSE Linux Enterprise

-

Processor (CPU): Intel® Xeon® or AMD EPYC™ multi-core processor (8+ cores recommended)

-

Memory (RAM): 16 GB minimum (32–64 GB recommended for large models)

-

Graphics (Optional): NVIDIA® CUDA-enabled GPU for enhanced visualization performance

-

Storage: SSD with at least 50 GB free space

-

Network: Required for license server and collaborative simulation workflows

🔹 Bug Fixes & Performance Enhancements

The BM-STAMP 2025 release includes critical bug fixes and technical improvements:

-

✅ Resolved solver crashes in large-scale springback simulations.

-

✅ Fixed meshing instabilities on complex part geometries.

-

✅ Optimized memory allocation for high-performance computing clusters.

-

✅ Improved CAD import/export reliability across multiple CAD formats.

-

✅ Reduced solver run-time for advanced high-strength steel (AHSS) simulations.

-

✅ Enhanced stability for batch processing and automation scripts.

🔹 Why Choose ESI BM-STAMP 2025?

The automotive industry is under pressure to deliver lighter, safer, and more cost-efficient vehicles. Stamping engineers face challenges with new materials, tighter tolerances, and reduced development cycles. BM-STAMP 2025 provides a powerful digital solution that helps organizations stay competitive by enabling virtual stamping tryouts, minimizing physical prototypes, and optimizing the entire stamping workflow.

By combining accuracy, usability, and scalability, BM-STAMP 2025 sets a new standard in stamping simulation software. Whether you are an OEM, Tier 1 supplier, or tooling company, BM-STAMP 2025 offers the right tools to design better products, reduce risks, and improve efficiency.

⭐️⭐️⭐️⭐️⭐️5/5

**“As a stamping process engineer, I’ve worked with several simulation tools, but BM-STAMP 2025 is by far the most intuitive and reliable stamping simulation software I’ve used. The new version has greatly improved defect prediction and springback simulation, which saves us weeks of physical tryouts and reduces production risks.

The Virtual Light Room feature is a game-changer for surface quality prediction, especially when working on Class-A panels. The token-based licensing is also a big plus, allowing our team to scale resources across projects without extra cost.

From a developer’s perspective, the interface is modern, easy to navigate, and integrates smoothly with our existing CAD/PLM systems. The performance on multi-core servers is excellent, and solver stability has noticeably improved compared to previous releases.

If you’re in automotive body manufacturing or sheet metal forming, BM-STAMP 2025 is an essential tool. It combines accuracy, speed, and usability in one package. Highly recommended.”**

— Senior Developer / Stamping Process Engineer

Related products

-

Metamation MetaCAM Enterprise 2017 with all modules

$ 170.00 Add to cart Quick View -

MasterCam 2025 full cracked release

$ 150.00 Add to cart Quick View -

Autoship 10.3.0 cracked release

$ 175.00 Add to cart Quick View -

GO2cam and GO2dental v6.11 cracked release

$ 200.00 Add to cart Quick View -

SheetWorks Series v19 sp3.0 (full cracked software)

$ 150.00 Add to cart Quick View -

PROCAM DIMENSIONS 5.4 cracked software download

$ 160.00 Add to cart Quick View -

AC-Tek Sidewinder 9.72 full cracked version

$ 160.00 Add to cart Quick View -

CAMTOOL V19.1.2 cracked release

$ 140.00 Add to cart Quick View -

Camtek PEPS CAD/CAM System 2024 cracked release

$ 160.00 Add to cart Quick View -

inLab SW 20.0 cracked license software

$ 200.00 Add to cart Quick View