Simcenter Testlab Neo 2506

$ 175.00

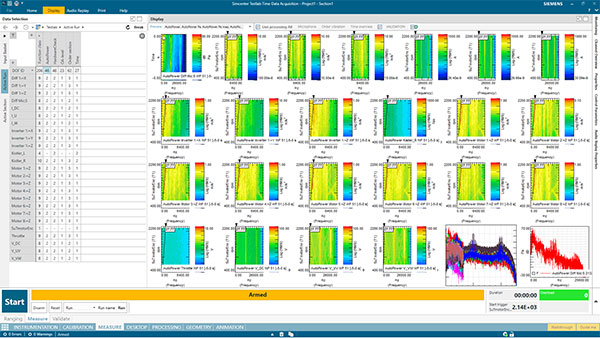

Simcenter Testlab 2506 is Siemens’ latest integrated test and measurement software designed for faster, smarter NVH testing, transfer path analysis (TPA), and component characterization. With advanced automation, AI-assisted workflows, and seamless hardware integration, Testlab 2506 helps engineers reduce test preparation time by up to 40%, improve data accuracy, and accelerate design validation. Ideal for automotive, aerospace, and industrial applications, it delivers powerful capabilities in noise, vibration, and durability testing while enabling closer collaboration between simulation and physical testing…

Description

Simcenter Testlab 2506 – Advanced Test & Measurement Software

Simcenter Testlab 2506 is the latest release of Siemens’ powerful test and measurement platform, built to accelerate noise, vibration, and harshness (NVH) testing, transfer path analysis (TPA), and durability engineering. This version introduces next-generation automation, AI-driven workflows, and enhanced hardware integration that significantly reduce manual work while delivering faster, more accurate results. Designed for the automotive, aerospace, rail, and industrial machinery industries, Simcenter Testlab 2506 helps engineering teams bridge the gap between physical testing and virtual simulation.

🚀 New Functions in Simcenter Testlab 2506

The 2506 release introduces several innovative features that take test automation and NVH analysis to the next level:

-

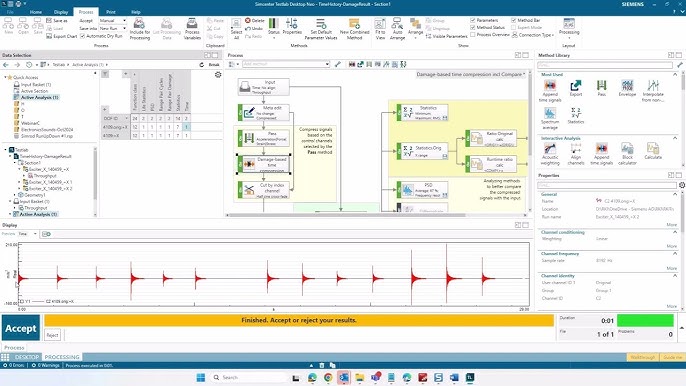

Redesigned Transfer Path Analysis (TPA): A fully automated workflow that shortens the journey from raw measurements to principal component results, saving engineers up to 40% of test preparation time.

-

Automated Component Model Extractor: A patented solution for faster blocked force measurements and NVH component characterization, making it easier to create accurate models for digital twins.

-

Parallel Analysis & Matrix Inversion: Perform multiple transfer path analyses simultaneously, reducing comparison time by nearly 30% while improving system accuracy.

-

AI-Enhanced Automation: Intelligent algorithms reduce repetitive tasks, eliminate human error, and ensure consistency across test campaigns.

-

Simcenter Testlab Neo Improvements: The next-generation Neo environment delivers better visualization, interactive analysis, and simplified in-situ TPA interpretation.

🌟 Key Highlights & Benefits

-

Accelerated NVH Testing: Run faster and more reliable measurements for vehicles, aircraft, trains, and industrial machinery.

-

Seamless Hardware Integration: Direct compatibility with Simcenter SCADAS hardware ensures high-quality, synchronized data acquisition.

-

Open Data Ecosystem: Easily export, import, and integrate test results with simulation tools for full test-simulation synergy.

-

Reduced Time-to-Market: Automated workflows free up engineers from manual tasks, helping companies shorten development cycles.

-

Better Decision-Making: High-accuracy component models allow earlier validation of product performance, even before physical prototypes are fully available.

🖥️ System Requirements for Simcenter Testlab 2506

To guarantee reliable performance, Siemens recommends the following system configuration:

-

Operating System: Windows 10 (64-bit) or Windows 11 Professional

-

Processor: Intel® Core™ i7 or equivalent AMD Ryzen (multi-core strongly recommended)

-

RAM: Minimum 16 GB (32 GB or higher for large NVH and durability datasets)

-

Storage: SSD with 50 GB of free disk space (NVMe recommended for large projects)

-

Graphics: DirectX 11 compatible graphics card with 2 GB dedicated VRAM or higher

-

Connectivity: USB/Ethernet for seamless SCADAS hardware connection

-

Additional Software: Microsoft Office 2019/365 for reporting and Excel data exchange

🔧 Bug Fixes & Performance Improvements

The Simcenter Testlab 2506 release also delivers a wide range of bug fixes, stability improvements, and optimizations:

-

Fixed instability issues when handling very large NVH datasets.

-

Improved memory management during long-duration durability tests.

-

Corrected occasional crashes in Process Designer workflows and Neo visualization.

-

Enhanced support for third-party file formats and simulation model integration.

-

More accurate matrix inversion calculations in transfer path analysis.

-

Faster and more reliable data export to external reporting tools.

🔑 Why Upgrade to Simcenter Testlab 2506?

With the growing demand for faster product development cycles, reduced prototyping costs, and improved product performance, Simcenter Testlab 2506 is designed to meet modern engineering challenges. By combining cutting-edge test automation, AI-enhanced analysis, and seamless SCADAS hardware integration, this release empowers engineers to:

-

Cut NVH test preparation time by up to 40%.

-

Run parallel analyses and get results 30% faster.

-

Build accurate component models for use in virtual prototypes and digital twins.

-

Achieve consistent, reliable results with automated workflows and reduced human error.

-

Connect physical testing with simulation environments for faster design validation.

🌍 Industries & Applications

Simcenter Testlab 2506 is trusted across industries for high-performance engineering:

-

Automotive: Vehicle NVH testing, electric vehicle sound design, transfer path analysis.

-

Aerospace & Defense: Aircraft vibration testing, cabin noise analysis, structural dynamics.

-

Railway & Transportation: Ride comfort analysis, bogie vibration studies, noise compliance.

-

Industrial Machinery & Energy: Rotating equipment diagnostics, wind turbine vibration testing, heavy-duty machinery durability validation.

✅ Conclusion

Simcenter Testlab 2506 represents a major leap in intelligent test automation and NVH engineering. With its powerful combination of automation, AI, improved TPA workflows, and enhanced hardware integration, it helps organizations reduce testing time, improve accuracy, and connect test data with digital simulation. For companies looking to stay ahead in competitive industries, upgrading to Simcenter Testlab 2506 ensures smarter, faster, and more reliable engineering testing.

⭐️⭐️⭐️⭐️⭐️5/5

As a developer and NVH engineer, I’ve been working with Simcenter Testlab 2506 for several months, and I can confidently say it is a major step forward in test and measurement software. The redesigned transfer path analysis (TPA) workflow has saved our team countless hours of manual data preparation, and the new Automated Component Model Extractor is a game changer for accurate NVH component characterization.

One of the biggest advantages is how seamlessly the software integrates with Simcenter SCADAS hardware, delivering high-quality data acquisition without compatibility issues. The AI-driven automation not only reduces repetitive tasks but also ensures consistency across different test campaigns. For large NVH datasets, the improved memory handling and stability in version 2506 have made a noticeable difference in performance.

From a development perspective, the flexibility to combine physical testing and digital simulation is invaluable. The fact that we can generate component models and immediately feed them into simulation workflows accelerates validation and supports the creation of more reliable digital twins.

Overall, Simcenter Testlab 2506 is a reliable, efficient, and forward-looking platform for anyone serious about NVH testing, durability engineering, or advanced transfer path analysis. I highly recommend it to other engineers and developers who want to cut testing time, improve accuracy, and stay ahead in a competitive industry.