MiriSys Software Suite (all modules\tools)

$ 230.00

Our software products are developed with using latest and modern development tools. Very close cooperation with our partners and users helps us to improve functionality and ergonomy of our products.

- Supported machines: CNC-cutters, CNC-lasers, CNC-routers, WaterJet, Milling centers, Roll-press

- Compatibility with standard data formats, like DXF, AAMA, ASTM, ISO

- Wide list of support hardware devices, like digitizers, cameras and projectors

- Power boost thanks to multi-core processors optimizations

- Interconnection with SQL database server

- Compatibility with Microsoft Windows 10, 8.1 and 7 (32 and 64 bit versions)

- Easy-to-use interface

Description

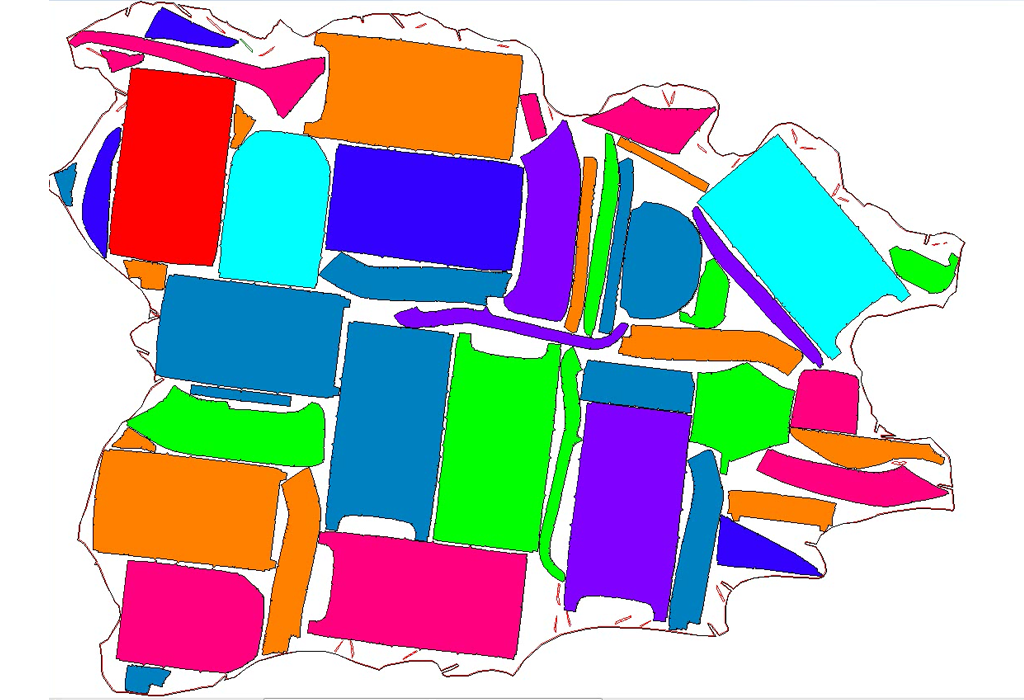

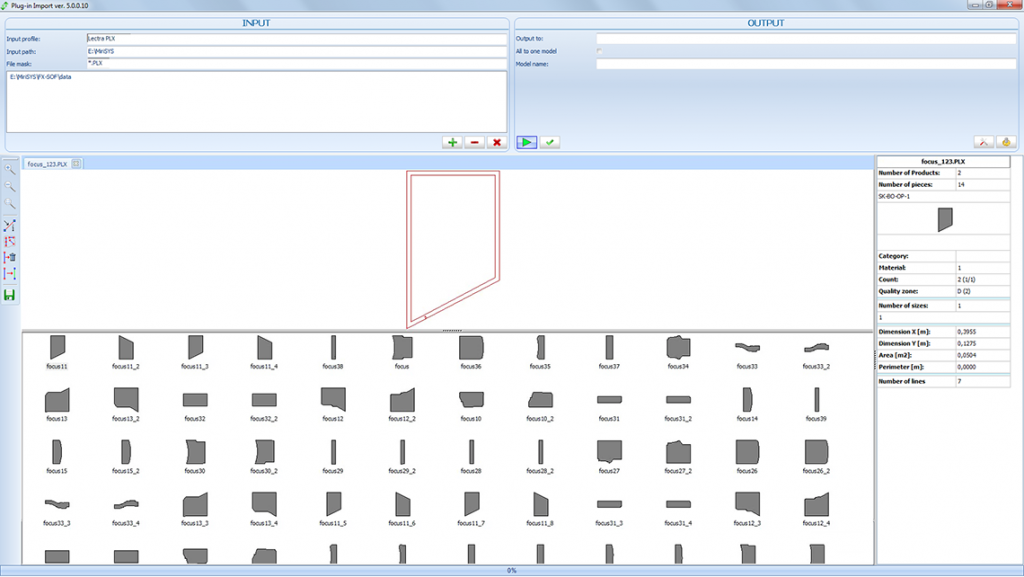

UniPDS

Universal easy-to-use CAD system used mainly in the leather and technical textile processing industry, automotive industry, upholstery industry, and similar applications.

Features:

- Creation of patterns by digitization, import or scanning

- Parameters of models, products and pieces

- Editing of pieces, lines and points

- Technological marks, sewing allowances

- Quality areas

- Available file or database version

Details:

The system contains functions which covers the creation of new models and patterns, from as early as their digitization and direct design. A fully hardware-accelerated user interface (OpenGL) allows easy and fast editing of the shape of the pieces and their parameters. With the use of additional plug-ins, users can easily import and then edit models from different data formats (use of predefined multi-operations), or scan pieces with high accuracy by digital camera.

Benefits:

- Easy-to-use

- Fully customizable interface

- Powerful multi-operations

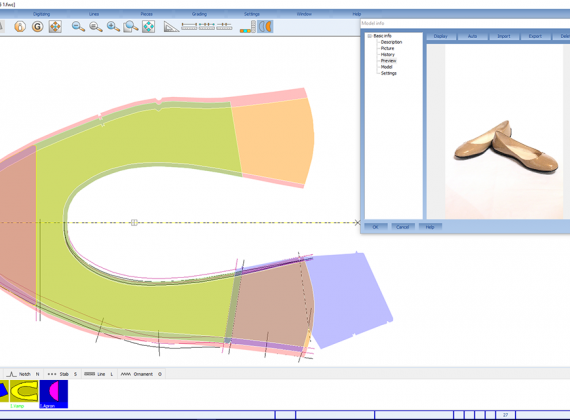

FootwearCAD

Professional 2D construction and grading system designed for producers of all kinds of shoe and leather goods.

Features:

- Creation of patterns by digitization, import or scanning

- Editing of lines and points

- Construction of pieces

- Technological marks, ornaments

- Grading

- Nesting and cutting or drawing of templates

Details:

The FootwearCAD is a perfect tool for large companies as well as for mid-sized and small companies. System markedly simplifies designers, modelers and technologists work and is ideal for a complete construction and grading of all pieces and templates of shoemaker design. The system consists of a big range of efficient functions for a modeler base digitalization through parts construction, automatic grading to the templates cutting or drawing.

Benefits:

- Higher work efficiency

- Automatization of production preparation

- Faster response to customer requirements

- Easy-to-use

GarmentCAD

Highly effective tool for garment producers. GarmentCAD covers the creation of new models, grading, templates drawing or export for nesting systems.

Features:

- Creation of patterns by digitization, import or scanning

- Editing of lines and points

- Construction of pieces

- Technological marks, ornaments

- Grading

- Nesting and cutting or drawing of templates

Details:

More information available upon the request.

Benefits:

- Higher work efficiency

- Automatization of production preparation

- Faster response to customer requirements

- Easy-to-use

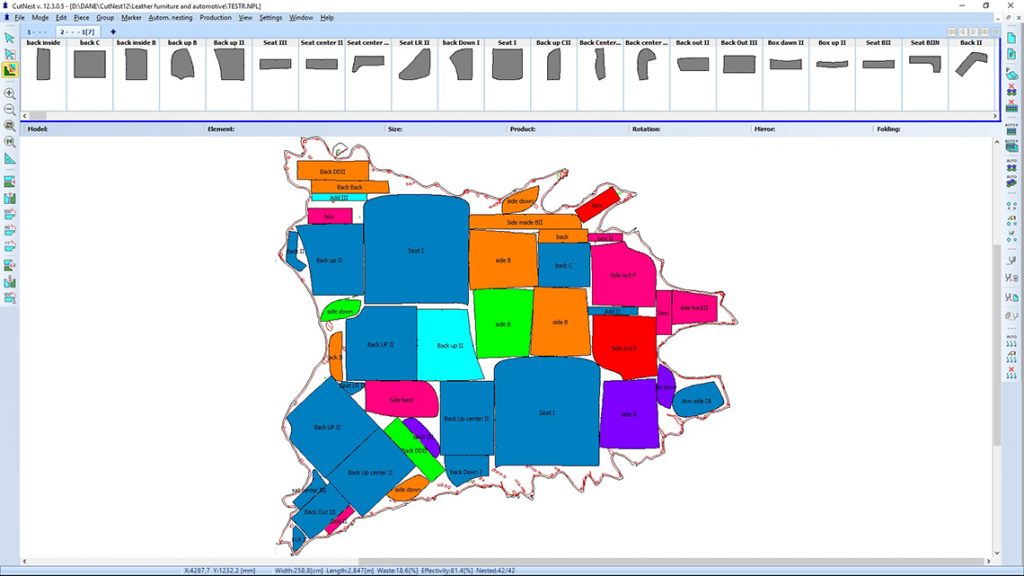

CutNest nesting and cutting system

System for nesting of pieces on textile, synthetic and leather materials with possibility of direct output to cutting and drawing machines.

Features:

- Model data from UniPDS or import from other CAD system

- Adjustment of marker and parameters of pieces

- Cutting optimization

- Automatic nesting

- Interactive nesting

- Possibility to work with leather shapes and quality areas

- Stripe and plaid matching

- Plan checking

- Direct outputs for cutting and drawing machines

Details:

The CutNest allows to create markers with use of interactive or automatic nesting of pieces on requested material size or shape. Markers can be also grouped by customer‘s order when particular number of requested models/products is entered. The CutNest enables direct communication between computer and output devices, such as large format printers, plotters and CNC-cutters.

Benefits:

- Material savings

- Improvement of productivity

- Easy-to-use

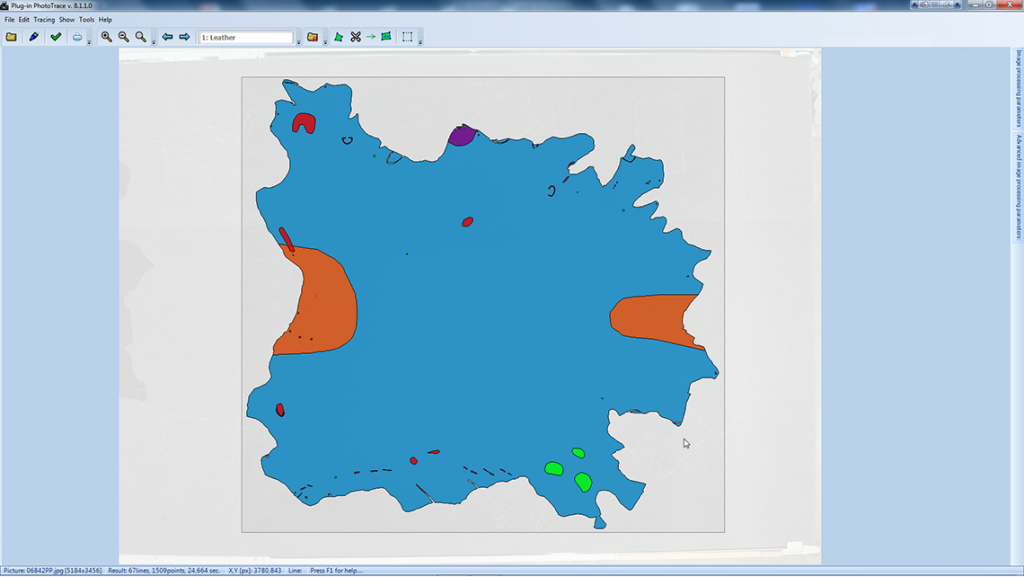

Automatic Nesting

Fully automatic nesting with the highest utilization of material.

Features:

- Nesting on leather with respecting of defects and quality areas

- Nesting on textile and other synthetic materials, including matching to stripes

- Adjustable time for nesting, adjustable number of tests per marker

- Compatible with single-layer and multi-layer cutters

- Nesting server – non-stop nesting without need of supervision

Details:

Fully automatic nesting module, which completely replaces difficult and time taking preparation of marker by method of interactive nesting, with maximal material utilization. Perfect solution for manufacturers who prepare large amounts of markers or use large amount of pieces. Connection with the CutNest enables to prepare pieces and material. According to set parameters of pieces and material, Automatic Nesting tries thousands of different variations for a set period of time and chooses the best one.

Three versions of Plugin AutoNest:

- AutoNest Leather – for leather hides

- AutoNest Textile – for textile and other synthetics materials

- AutoNest Insole – optimized for shoe insoles

Benefits:

- Significant material savings

- Fully automatic nesting

- Easy-to-use

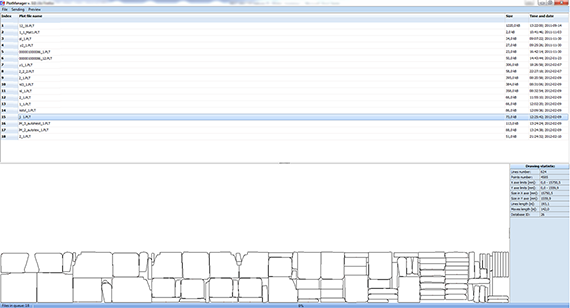

PlotManager

Management of a queue of data for cutting and enables direct connection and data-transfer between computer and CNC-cutter.

Features:

- Use of models from MiriSys CAD systems or import from other CAD systems

- Data-transfer between computer and CNC-cutter

- Controlling of a queue of data for cutting

- Monitoring of the communication

- Record of statistic information

Details:

PlotManager provides data connection between computer and a CNC-cutter.

It is used for CNC-cutters, which are directly connected with the computer via serial or parallel cable. PlotManager enables to manage a queue of cutting data: start of cutting, pause or cancel data sending. It is possible to record statistic data of production. This data can be monitored online from a remote workplace and transfer them into MRP System for purpose of monitoring and managing the production.

Benefits:

- Various connection types: COM, LPT, Ethernet

- Preview of HPGL data

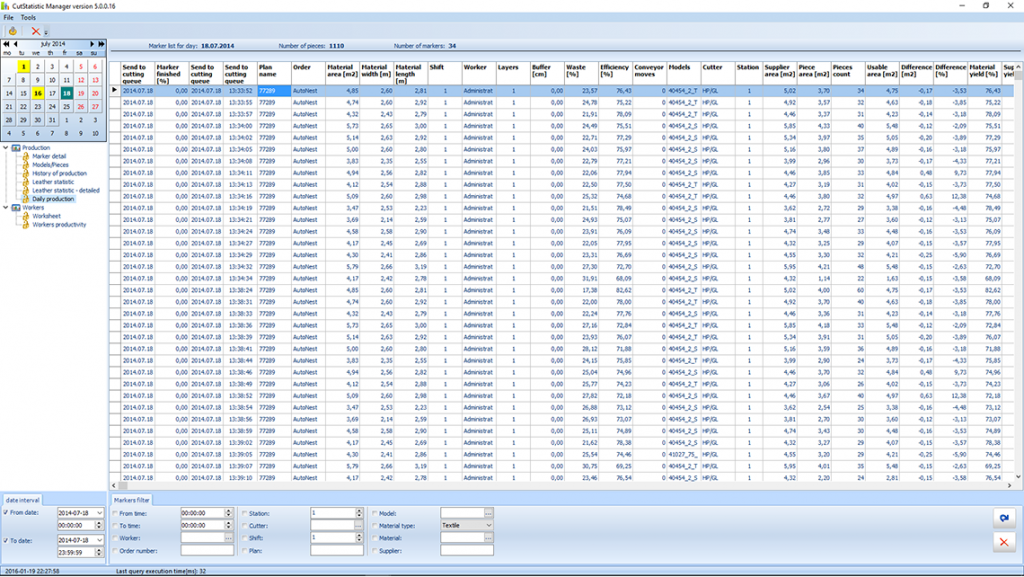

CutStatistic

Evaluation of recorded statistic data of production on cutters.

Features:

- Recording of statistic information about cut plans into database

- Reports (tables and charts) for selected time interval

- Report of production history

- Report of number of models, pieces, workers, productivity, etc.

- Printouts of reports

Details:

CutStatistic system records the statistic data into database. The source of data is CutNest system, which gathers following information: names of cut plans and models, list and quantity of pieces, time of cutting, material area, waste, efficiency, picture of marker, etc. The CutStatistic application enables to work with database and create reports for selected time interval, shift, worker, materials, models, etc. Following reports are available: History of production, Marker (plan) details, Models/pieces, Worksheet, Workers productivity. All reports can be customized and additional reports can be prepared.

Benefits:

- Online monitoring of production

- Remote access to database

- Export to Excel or other data formats