Detect3D v2.70 by Insight Numerics

$ 200.00

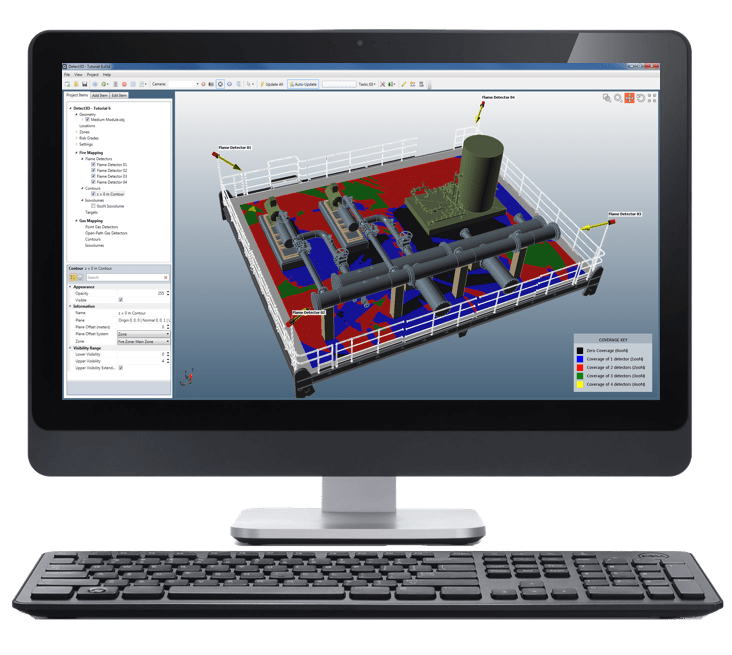

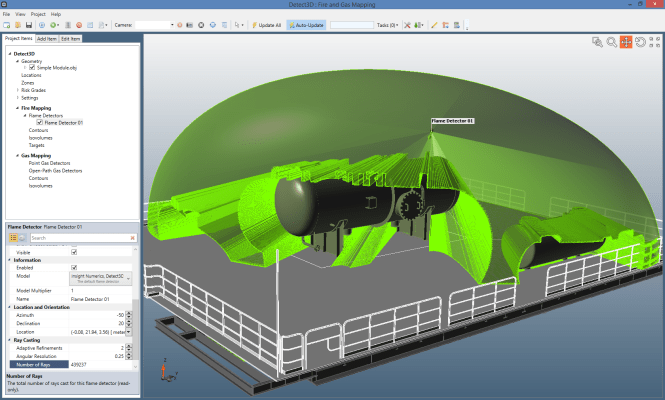

Detect3D – Advanced Fire & Gas Mapping Software by Insight Numerics

Detect3D is a leading 3D fire and gas mapping solution used by engineering firms and industrial safety teams worldwide. With high-precision modeling, intuitive workflows, and powerful optimization tools, Detect3D helps you design safer facilities and ensure full detector coverage. Ideal for oil & gas, energy, chemical, and high-risk industrial environments, this software delivers fast performance, reliable analysis, and accurate compliance reporting…

Description

Detect3D v2.70 – Advanced 3D Fire & Gas Mapping Software by Insight Numerics

The industry’s most accurate and efficient fire & gas detector positioning tool — now more powerful than ever.

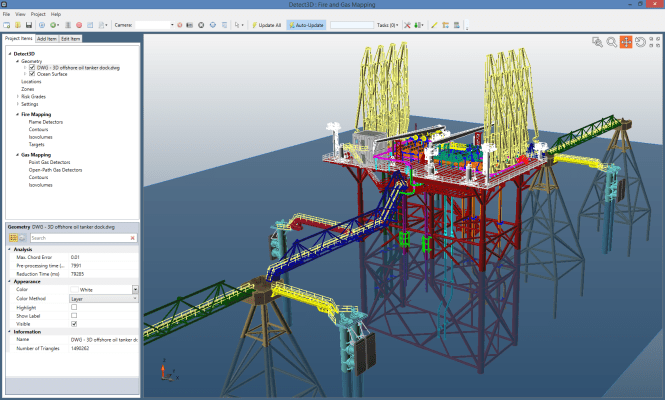

Detect3D v2.70 is the latest major release of Insight Numerics’ world-leading 3D Fire and Gas Mapping software. Built for industrial safety engineers, risk consultants, and process design teams, Detect3D delivers ultra-fast performance, true 3D ray-casting accuracy, intuitive workflows, and unmatched reporting quality — making it the preferred solution for safety-critical industries worldwide.

Designed for oil & gas, LNG, hydrogen, petrochemical, onshore/offshore facilities, FPSOs, refineries, and energy sectors, Detect3D sets the standard for modern fire & gas mapping.

⭐ What’s New in Detect3D v2.70

The 2.70 release introduces a series of enhancements focused on increasing accuracy, improving workflow efficiency, and expanding compatibility with third-party engineering tools.

✔ Acoustic Detector “2ooN+” Configuration

A new feature allows acoustic gas detectors to count only toward two-out-of-N or higher coverage tiers for specific risk grades. This provides more realistic coverage calculations when combining flame, gas, toxic, and acoustic detection technologies.

✔ Full Compatibility with in:Flux 4.0

Detect3D v2.70 integrates seamlessly with in:Flux v4.0, Insight Numerics’ Computational Fluid Dynamics (CFD) package.

This enables cross-analysis of:

-

Gas dispersion

-

Ventilation efficiency

-

Smoke and fire propagation

-

Gas cloud size and frequency

-

Detector response to realistic gas cloud scenarios

✔ Improved Geometry Handling & Project Stability

-

Safer merging of projects with missing or incomplete geometry

-

Better memory handling with large + complex CAD models

-

Faster view manipulation in heavy 3D scenes

-

More robust autosave and scene caching

✔ UI Improvements & Visualization Enhancements

-

Updated detector label coloring logic

-

Cleaner detector-on/off visibility states

-

Enhancement to swept-type field-of-view calculations

-

Smoother transparency, clipping, and 3D slicing performance

-

More intuitive navigation controls

🌟 Core Features & Highlights

Detect3D is built to significantly accelerate the full lifecycle of fire & gas mapping — from initial facility modeling to optimization, analysis, and reporting.

🔥 Ultra-Accurate 3D Ray-Casting Algorithm

Detect3D simulates tens of thousands of rays for flame and gas detectors, accounting for:

-

Occlusion by equipment and structures

-

Blind spots

-

Partial coverage

-

Detector FOV shape, degradation curves, and off-axis performance

-

Refined angular sampling for high-precision results

This produces the industry’s most accurate detector coverage predictions.

🧬 Genetic Algorithm Detector Optimization

Reduce detector count while improving safety coverage.

The system automatically:

-

Tests thousands of layout combinations

-

Considers coverage targets (1ooN, 2ooN, etc.)

-

Avoids installation conflicts

-

Evaluates line-of-sight constraints

-

Optimizes for cost & risk reduction

Yet the engineer retains full visibility and control over every step.

🏗 Comprehensive CAD Integration

Import CAD from almost any engineering workflow:

-

DGN, DWG, DXF, DWF

-

IGES, STEP

-

STL, OBJ

-

Navisworks-compatible exports

-

Direct engineering model imports from EPC partners

Detect3D handles massive plant models smoothly, automatically validating geometry for ray-casting.

Built-in CAD Creator

If only 2D drawings exist, Detect3D allows users to:

-

Extrude walls

-

Create cylinders, ducts, and pipes

-

Build platforms, equipment blocks, and obstacles

-

Add custom primitives and parametric shapes

Perfect for early-stage design.

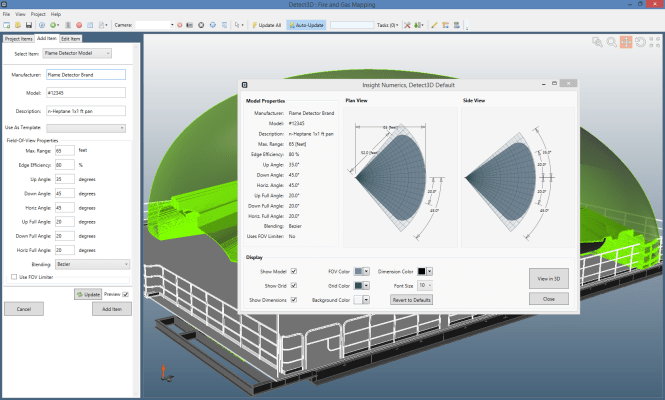

🎯 Accurate Detector Library & Customization

Detect3D includes a large manufacturer-verified database of:

-

Flame detectors

-

Gas detectors

-

Toxic sensors

-

Acoustic leak detectors

-

Point, open-path, and camera-type detectors

-

Cone, pyramid, swept, “fan,” and Bezier-defined FOVs

Users can also define completely custom fields-of-view.

📊 Advanced Coverage Visualization

Visualize coverage using:

-

3D isovolumes (colored leak zones, flame coverage clouds)

-

2D contour maps (0ooN, 1ooN, 2ooN coverage)

-

Interactive cross-sections

-

Clip planes

-

Detector contribution analysis

Engineers can isolate zones by platform, equipment type, or risk level.

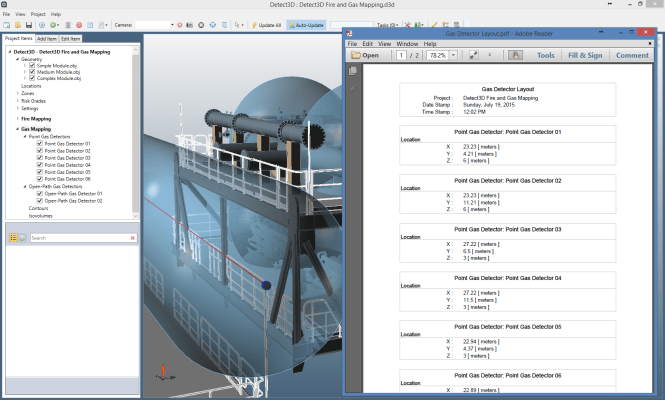

📝 Powerful Reporting Tools

Generate professional reports instantly:

-

Excel spreadsheets with detector summaries

-

PDF coverage reports

-

High-resolution 3D images

-

Detector ranking tables

-

Zone-by-zone coverage grading

-

Exportable tables and graphics for HAZOP / SIL reviews

Everything is ready for clients, regulators, or EPC partners.

🔒 Risk-Grade-Based Sub-Zoning

Automatically create sub-zones around:

-

Pumps

-

Compressors

-

Turbines

-

Vessels

-

Well bays

-

Process skids

Then tie coverage targets directly to risk categories for compliance purposes.

🤝 Collaboration & Review Tools

Detect3D offers:

-

Free Viewer Mode (no license required)

-

Project versioning

-

Easy sharing of .d3d files

-

Clean scene snapshots for presentations

-

Annotation and labeling options

⚙ System Requirements

Minimum Requirements

-

Windows 10 or newer (64-bit)

-

~1.5 GHz x64 CPU

-

8 GB RAM

-

Integrated graphics GPU

-

~2 GB free disk space

-

Microsoft .NET Framework 4.8

Recommended for Large Projects

-

2.3+ GHz multi-core processor

-

16–32 GB RAM

-

Dedicated GPU (2 GB VRAM or higher)

-

SSD for storage

-

Dual-monitor setup for CAD + analysis

🐞 Bug Fixes in v2.70

-

Fixed merging issues when geometry is missing

-

Resolved a rare swept-FOV coverage calculation error

-

Corrected label coloring inconsistencies in detector visibility toggle

-

Improved stability when importing large or malformed CAD files

-

Smoother GPU-based rendering during clipping and slicing

-

Various UI refinements and stability patches

📌 Why Detect3D Is Trusted Worldwide

-

Used by Shell, BP, Chevron, TotalEnergies, Maersk, Wood, McDermott, Worley, and many more

-

Designed for both offshore + onshore facilities

-

Helps companies reduce mapping study costs by up to 70%

-

Fully validated and accepted in global regulatory environments

-

Supported by extensive tutorials and training

-

Integrates directly with CFD analysis via in:Flux

🚀 Why Choose Detect3D v2.70?

Detect3D v2.70 delivers:

-

More accurate mapping than manual methods

-

Far faster analysis than legacy tools

-

Better visualization for decision-making

-

Clear documentation for audits and compliance

-

Significant cost savings through optimization

-

Stable, modern architecture built for huge CAD models

-

Tight integration with CFD for deeper safety analysis

It is the gold standard for modern fire & gas mapping.

⭐⭐⭐⭐⭐ “Outstanding Fire & Gas Mapping Tool — Essential for Any Safety Engineering Workflow”

As a developer and safety engineering specialist who has integrated Detect3D into multiple design and analysis workflows over the past several years, I can say with confidence that this software remains the most reliable, accurate, and developer-friendly fire and gas mapping solution on the market.

From a technical standpoint, Detect3D’s ray-casting engine, genetic-algorithm optimization, and CAD integration capabilities deliver performance that is consistently precise, stable, and incredibly efficient — even when working with extremely large and complex 3D facility models. The latest version (v2.70) introduces meaningful improvements, especially in acoustic detector handling, in:Flux compatibility, and visualization stability, all of which contribute to smoother, faster project execution.

What I appreciate most as a developer is the software’s predictable architecture, clean data structure, and reliable workflow automation, which make it easy to maintain consistent results across teams. The reporting system is also exceptionally polished — producing clear, audit-ready Excel and PDF outputs without manual cleanup.

Detect3D continues to be an absolute asset for projects requiring high-precision fire & gas coverage, 3D modeling accuracy, and compliance-focused documentation. It has dramatically reduced both analysis time and the number of detectors required in several of our industrial layouts, directly improving safety performance and project economics.