GEXCON FLACS 25.2

$ 170.00

FLACS by Gexcon is advanced CFD software for explosion, fire, and gas dispersion modeling. Now with water spray and inerting system simulation. Ideal for industrial safety and QRA…

Description

FLACS 25.2 – Industry-Leading CFD Software for Explosion, Fire, and Gas Dispersion Risk Analysis

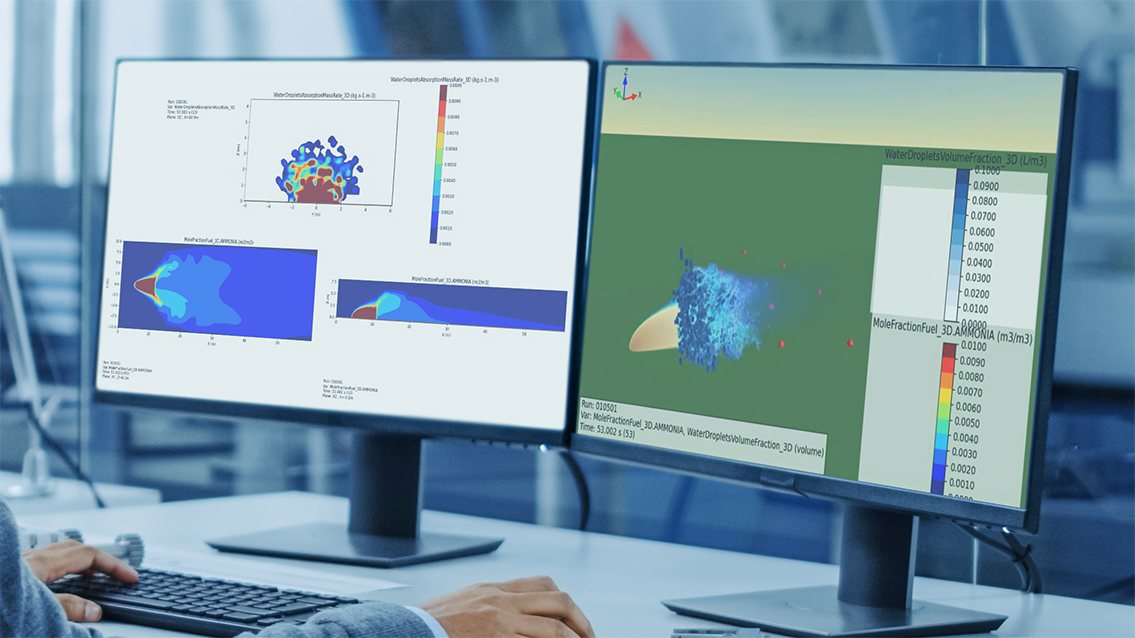

FLACS 25.2 by Gexcon is the latest release of the world-renowned CFD (Computational Fluid Dynamics) software used for simulating and analyzing explosion hazards, fire scenarios, and toxic or flammable gas dispersion in industrial environments. Built specifically for engineers, safety consultants, and risk analysts, FLACS is widely adopted across the oil & gas, chemical processing, energy, and marine sectors to ensure regulatory compliance and safeguard operations from catastrophic events.

With FLACS 25.2, Gexcon introduces significant upgrades that deliver more accurate, dynamic, and high-performance modeling than ever before. This version is ideal for safety professionals who require high-fidelity modeling of complex real-world environments and scenarios involving explosion and fire dynamics.

🔄 What’s New in FLACS 25.2

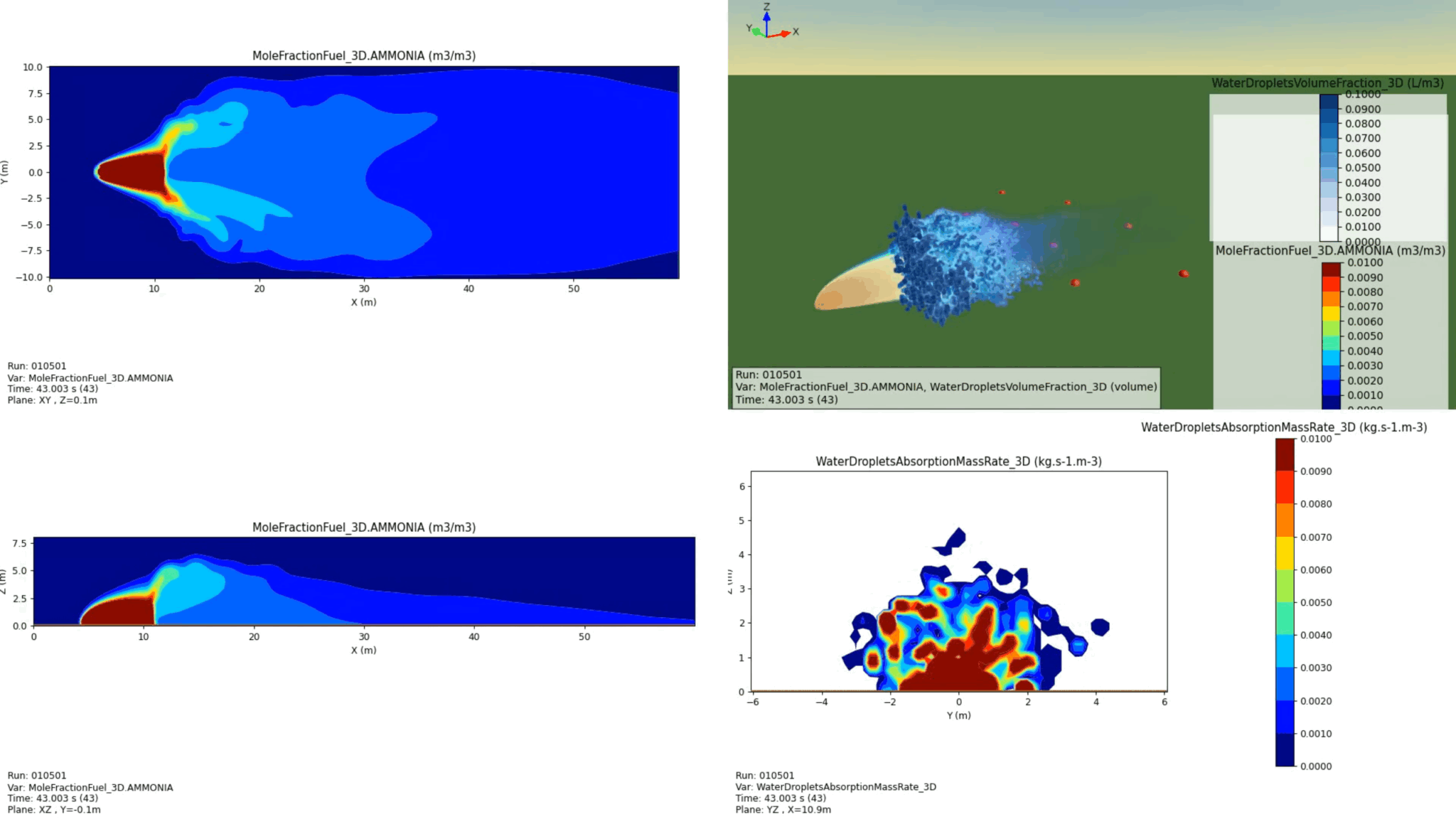

🌊 Dynamic Water Spray Modeling

One of the most anticipated features in FLACS 25.2 is the real-time simulation of water-based mitigation systems, including sprinklers, deluge systems, and fogging nozzles. Engineers can now model how water spray affects gas cloud dispersion and flame propagation. This breakthrough enables risk mitigation systems to be evaluated under realistic CFD conditions for the first time.

🧪 Inerting System Simulation

The new inert gas simulation tools allow users to model how CO₂, nitrogen, or other inert gases reduce the oxygen concentration in enclosures, piping, or vessels. This helps assess and design explosion-prevention systems for tanks, purged lines, and confined spaces where ignition must be avoided.

⚙️ Solver Performance and Stability Improvements

FLACS 25.2 brings major enhancements to its computational core, including better solver convergence, multi-core CPU optimization, and faster mesh generation. Users benefit from reduced simulation run times and greater reliability, especially when working with high-resolution geometries and large 3D models.

📊 Enhanced Visualization and Reporting

The built-in visualizer now renders more detailed 3D animations of flame fronts, pressure waves, and gas clouds with improved clarity and export features for technical reports. Output data is easier to interpret, making FLACS more powerful for communication with stakeholders, inspectors, and project teams.

🌟 Core Highlights & Key Features

-

✔️ Simulates gas explosions, BLEVE, deflagration-to-detonation transitions (DDT), and flash fires

-

✔️ Accurate gas dispersion and ventilation studies in open or congested environments

-

✔️ Validated against over 40 years of experimental explosion and fire data

-

✔️ Integration with QRA tools like EFFECTS, RISKCURVES, and FLACS2RC

-

✔️ User-friendly 3D modeling interface for complex industrial facilities

-

✔️ Fully documented technical library with over 100 modeling examples

-

✔️ Suitable for onshore and offshore platforms, refineries, process plants, LNG terminals, and storage facilities

💻 System Requirements

To run FLACS 25.2 efficiently, your system should meet the following specifications:

| Component | Minimum Requirements | Recommended Specs |

|---|---|---|

| OS | Windows 10 / 11 (64-bit) | Windows 11 Pro (64-bit) |

| CPU | Intel Core i7 / AMD Ryzen 7 | Intel Core i9 / AMD Ryzen 9 |

| RAM | 16 GB | 32–64 GB |

| Storage | 10 GB free space | SSD with 50+ GB available |

| Graphics | OpenGL-compatible, 2 GB VRAM | NVIDIA GeForce RTX 3060 or better |

| Display | 1920×1080 resolution | 2560×1440 or 4K UHD display |

| Dependencies | .NET Framework 4.8, Visual C++ Redistributables | Same, fully updated system drivers |

🐛 Bug Fixes & Performance Enhancements in FLACS 25.2

Gexcon addressed several user-reported issues to improve reliability and performance:

-

✅ Fixed mesh boundary errors that caused instability during indoor explosion simulations

-

✅ Resolved flame front inaccuracies in scenarios with rapid pressure changes

-

✅ Improved post-processing stability for large, high-resolution models

-

✅ Fixed graphical user interface (GUI) bugs on high-DPI displays

-

✅ Enhanced visualization accuracy of water spray and inert gas effects

-

✅ Corrected inconsistencies in transient simulation outputs when water mist was present

👥 Who Should Use FLACS 25.2?

FLACS 25.2 is essential for:

-

Process Safety Engineers modeling worst-case explosion or gas dispersion scenarios

-

CFD Specialists seeking high-fidelity, validated software for hazard modeling

-

Risk Analysts performing quantitative risk assessments (QRA)

-

HSE Teams designing mitigation strategies involving water spray or inerting

-

Design & EPC Firms needing to validate facility layouts against explosion pressures

-

Regulatory Consultants working in line with Seveso, OSHA, or ATEX guidelines

🎯 Why Choose FLACS 25.2?

-

🔬 Over 40 years of validation and global industry trust

-

🚀 Powerful modeling of real-world, high-risk industrial environments

-

📈 Enhanced features specifically tailored for modern process safety challenges

-

🌍 Trusted by major oil, gas, chemical, and energy companies worldwide

⭐️⭐️⭐️⭐️⭐️

“FLACS 25.2 is a major leap forward for industrial CFD modeling”As a process safety engineer working extensively in explosion modeling and gas dispersion analysis, I’ve used several CFD tools over the past decade. FLACS 25.2 stands out as one of the most robust, accurate, and application-specific solutions currently available in the industry.

The new dynamic water spray modeling feature is a game-changer. It allows me to simulate realistic mitigation systems, such as deluge and sprinkler networks, and see their true effect on gas cloud behavior and explosion overpressure. This is crucial for validating risk reduction measures in hazardous zones.

The improved support for inerting systems—including modeling the effects of nitrogen and CO₂—is incredibly valuable for confined space protection and assessing ignition prevention strategies. Combined with the faster solver performance and enhanced visualization tools, FLACS 25.2 offers both technical depth and practical usability.

Whether for detailed consequence modeling, QRA integration, or toxic gas dispersion studies, FLACS provides a validated and scalable platform that meets real-world engineering needs. The documentation is clear, and Gexcon’s support has been consistently responsive and knowledgeable.

If you’re serious about explosion safety and high-fidelity CFD, FLACS 25.2 is absolutely worth the investment.

Highly recommended. Five stars.

– Senior CFD Engineer, Energy Sector