ESKO Cape Pack Advanced cracked version

$ 200.00

Description

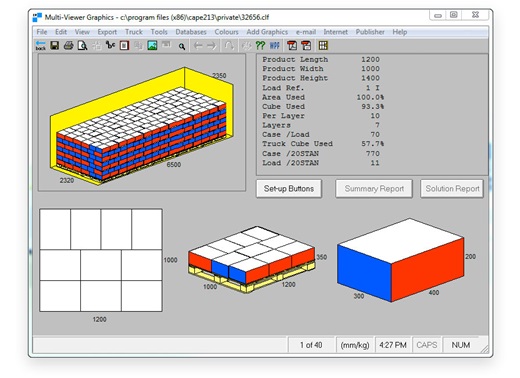

Palletization Software

Companies around the world are using Esko’s Cape Pack palletization software to reduce their ecological footprint. Cape Pack helps you:

- Design the optimum product size

- Evaluate alternative case sizes

- Maximize pallet loading

- Create a sustainable packaging supply chain

- Improve space utilization

- Cut transportation costs

- Reduce your carbon footprint

- Reduce the number of trucks on the streets

Optimized palletization

how does it work?

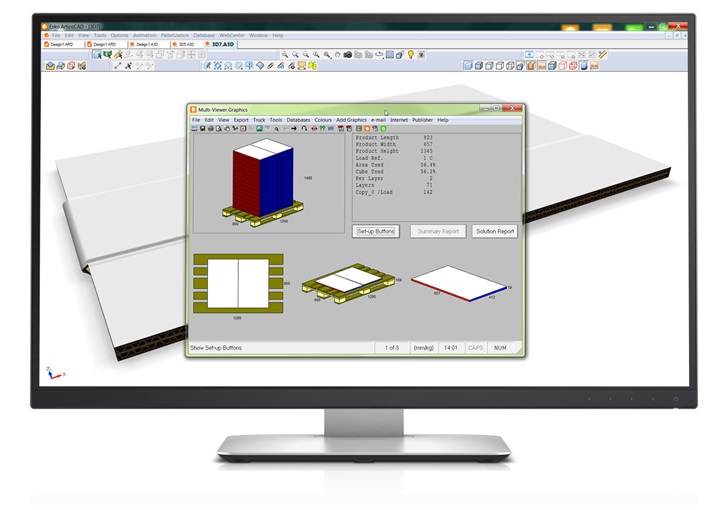

Start with an existing case size, an existing product size or use Cape Pack to determine the most appropriate size for a new product.

- Enter product dimensions.

- Specify case/tray type, pick a pallet and enter maximum load weight and height.

- Calculate and view case counts and pallet loads.

- Choose a palleting load and create a report which you can print, email, upload to the cloud or use to interface with another program application.

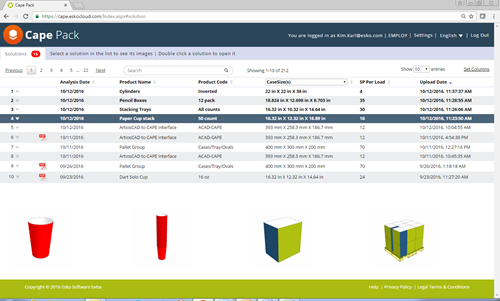

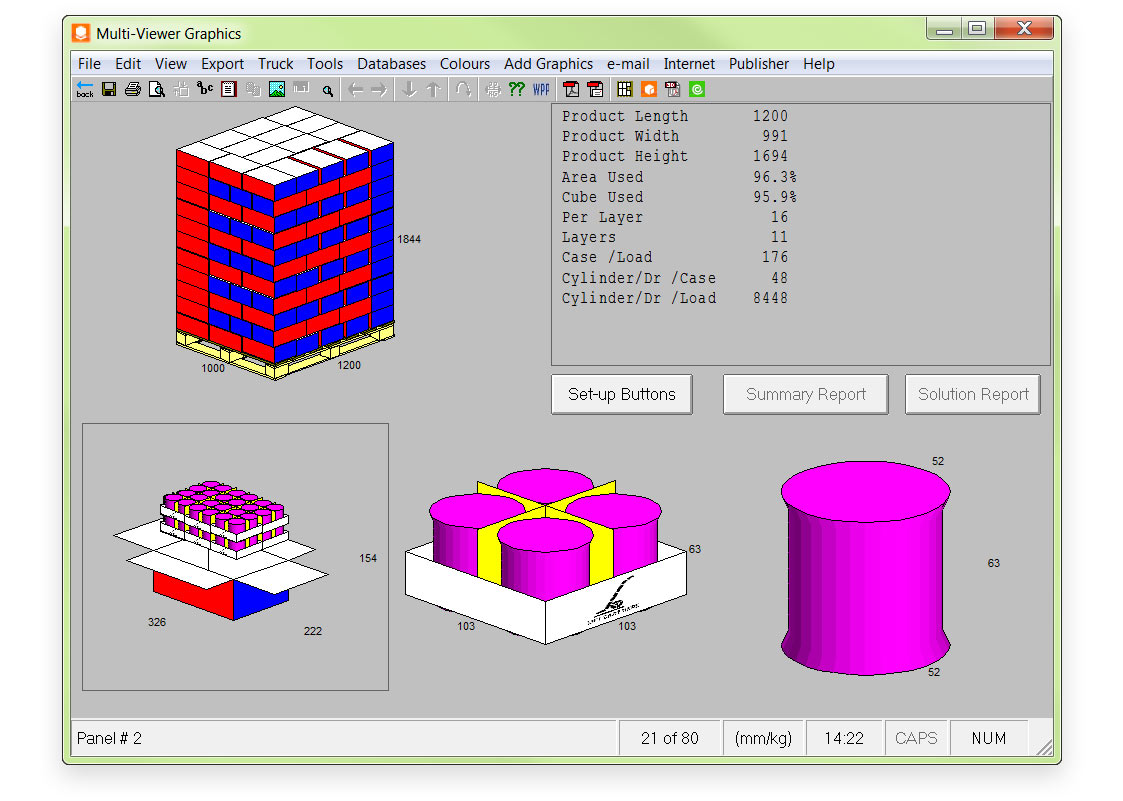

Cape Pack in the Cloud

Cape Pack users can upload critical up-to-the-minute information with colleagues around the corner or around the globe to speed up design and approval processes. Sharing palletization designs directly in the cloud cuts cycle times and delivers faster time to market.

Cape Pack Cloud makes it very easy to upload designs for folding cartons, cases and pallets. The pallet software supports cartons, cylinders and trapezoids as well as trays and bundles.

Cape Pack in the Cloud

Cape Pack users can upload critical up-to-the-minute information with colleagues around the corner or around the globe to speed up design and approval processes. Sharing palletization designs directly in the cloud cuts cycle times and delivers faster time to market.

Cape Pack Cloud makes it very easy to upload designs for folding cartons, cases and pallets. The system supports cartons, cylinders and trapezoids as well as trays and bundles.

Palletization

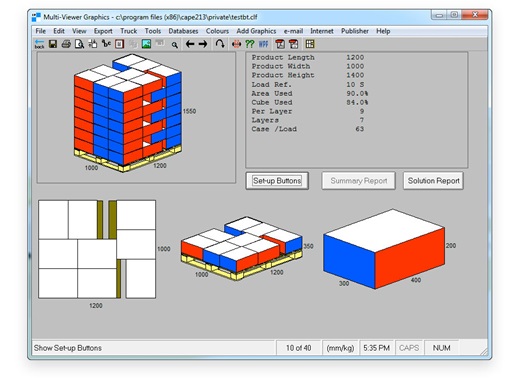

This program calculates pallet patterns for fixed or known secondary package sizes.

You enter the size of the bottle, box, tray, case, bag, etc. that is to be placed directly onto the pallet. It will allow you to calculate pallet patterns on 3 different sets of pallet restrictions at one time in order to compare efficiencies.

Mixed Loading

A separate program will allow you to create Display Pallets with mixed case or tray sizes.

You can use this program for a single mixed load or you can fill a full order of items with the Order Fulfillment option.

KDF for Corrugated manufacturers

Our Knocked-Down-Flat program is perfect for helping estimate full loads of flat cases that are to be shipped to your customer.

Packaging Design

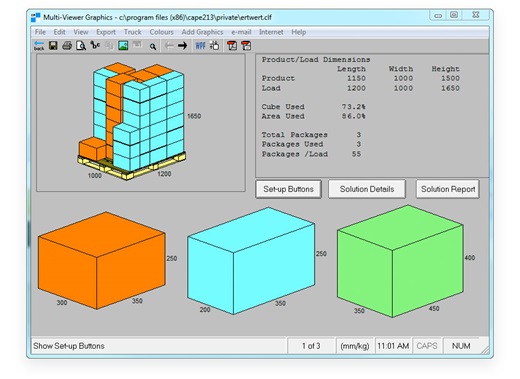

Cape Pack Advanced allows you to start with your known primary package or product size, and then design alternative shipper, tray or case sizes based on quantity, pack arrangement, orientation, and bundle requirements. You can evaluate your results including different bundle arrangements, case arrangements, divider styles and pallet loading options. This information can then be sent to ArtiosCAD or WebCenter through direct interface features.

Product Design

In addition to designing packaging for your products, Cape Pack Advanced program can also help you design or redesign your Product sizes. Starting from a known size, you can evaluate dimensional changes in your product sizing, with or without changing the volume of the product, to maximize your packaging and shipping space. Ship dramatically more in the same space.

Folding Carton Arrange

The Advanced program also includes our Folding Carton Arrange program which is designed to give Folding Carton makers a tool to help design cases for their flat folded cartons.

The numbers don’t lie

Companies around the world are using Esko’s Cape Pack and Cape Truckfill to reduce their ecological footprint. Cape Pack is dedicated palletizing software that allows you to improve product sizing and to create new case sizes, build the most efficient pallet design; and improve material and cube utilization.

Using Cape Pack software, one of the world’s largest pre-packaged food companies optimized its packaging and pallet layout. The results speak for themselves:

- The new, improved, package uses 78% less material by weight

- It uses 66% less corrugate or 778 fewer trees (114 tons) per 1000 pallets of product

- The new design saves 933 million BTU’s per 1000 pallets

- Saves 184,943 lbs (83888.73kg) of CO2 per 1000 pallets

- Saves 465,281 gallons (1761,28 m³) of waste water per 1000 pallets

- Saves 51,670 lbs (23437,11kg) of solid waste per 1000 pallets

- The new package offers 32% reduction of fossil fuel consumption & GHG emissions over the old package